by Bruce Wells | Feb 23, 2024 | Petroleum Technology

Reversing an earlier ban, voters in Long Beach, California, in 1962 approved petroleum exploration in their harbor. Five major oil companies formed a company called THUMS and built four artificial islands to produce the oil.

California’s headline-making 1921 oil discovery at Signal Hill launched a drilling boom that transformed the quiet residential area. So many derricks sprouted it became known as “Porcupine Hill.”

Island Grissom, one of the four THUMS islands at Long Beach, California, was named after NASA astronaut Col. Virgil “Gus” Grissom, who died in 1967 in the Apollo spacecraft fire. Photo courtesy U.S. Department of Energy.

With many homeowners aspiring to become drillers and oilfield speculators, much of Signal Hill’s land was sold and subdivided in real estate lots of a size described as “big enough to raise chickens.”

Derricks were so close to one cemetery that graves “generated royalty checks to next-of-kin when oil was drawn from beneath family plots,” noted one historian. Neighboring Long Beach joined the drilling boom.

By 1923, oil production reached more than one-quarter million barrels of oil per day. When Long Beach instituted a per-barrel oil tax, Signal Hill residents voted to incorporate in 1924.

At the time, “the law of capture” for petroleum production ensured the formerly scenic landscape would be transformed. Competing exploration and production companies crowded around newly completed wells and chased any signs of oil to the Pacific Ocean.

The islands are among the most innovative oilfield designs in the world. Circa 1965 illustration courtesy Oxy Petroleum.

By the early 1930s, the massive Wilmington oilfield extended through Long Beach as reservoir management concerns remained in the future. Naturally produced California oil seeps had led to many discoveries south of the 1892 Los Angeles City field.

Onshore and offshore tax revenues generated by production of more than one billion barrels of oil and one trillion cubic feet of natural gas helped underwrite much of the Los Angeles area’s economic growth. But not without consequences.

Long Beach: A Sinking City

The U.S. Army Corps of Engineers reported, “Subsidence, the sinking of the ground surface, is typically caused by extracting fluids from the subsurface.”

Petroleum reserves brought drilling booms to southern California. By 1923, oil production reached more than one-quarter million barrels of oil per day from Signal Hill, seen in the distance in this detail from a panorama from the Library of Congress.

Californians had a lot of experience dealing with groundwater induced subsidence and the building damage it caused, but by 1951, Long Beach was sinking at the alarming rate of about two feet each year.

Earth scientists noted that between 1928 and 1965, the community sank almost 30 feet. TIME magazine call the bustling port “America’s Sinking City.”

After decades of prospering from petroleum production, the city prohibited “offshore area” drilling to slow the subsidence as the community looked for a solution.

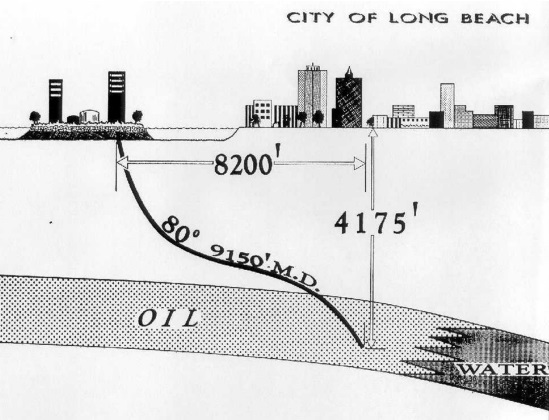

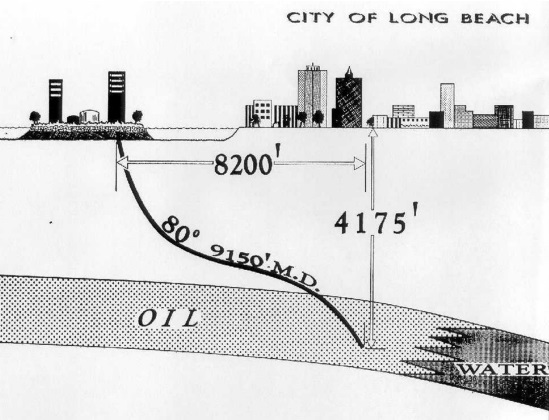

On February 27, 1962, Long Beach voters approved “controlled exploration and exploitation of the oil and gas reserves” underlying their harbor. The city’s charter had prohibited such drilling since a 1956 referendum. Advancements in oilfield technologies enabled Long Beach to stay afloat.

Directional drilling and water injection opened another 6,500 acres of the Wilmington field — and saved the sinking city.

THUMS: Texaco, Humble, Union and Shell

Five oil companies formed a Long Beach company called THUMS: Texaco (now Chevron), Humble (now ExxonMobil), Union Oil (now Chevron), Mobil (now ExxonMobil) and Shell Oil Company. They built four artificial islands at a cost of $22 million in 1965 (more than $200 in 2024 dollars).

The islands — named in 1967 Grissom, White, Chaffee, and Freemen in honor of lost NASA astronauts would include 42 acres for about 1,000 active wells producing 46,000 barrels of oil and 9 million cubic feet of natural gas a day.

The prospering but “sinking city” of Long Beach would solve its subsidence problem with four islands and advanced drilling and production technologies. Photo by Roger Coar, 1959, courtesy Long Beach Historical Society.

To counter subsidence, five 1,750-horsepower motors on White Island drive water injection pumps to offset extracted petroleum, sustain reservoir pressures, and extend oil recovery. The challenge was once described as “a massive Rubik’s Cube of oil pockets, fault blocks, fluid pressures and piping systems.”

Meanwhile, all of this happens amidst the scenic boating and tourist waters in Long Beach Harbor.

The California Resources Corporation operates the offshore part on the islands of the Wilmington field, the fourth-largest U.S. oilfield, according to the Los Angeles Association of Professional Landmen, whose members toured the facilities in November 2017.

Producing in Plain Sight

“Most interestingly, the islands were designed to blend in with the surrounding coastal environment,” explained LAAPL Education Chair Blake W.E. Barton of Signal Hill Petroleum.

“The drilling rigs and other above-ground equipment are camouflaged and sound-proofed with faux skyscraper skins and waterfalls,” Barton noted.

Most people simply do not realize the islands are petroleum production facilities. From the shore, the man-made islands appear occupied by upscale condos and lush vegetation. Many of the creative disguises came courtesy of Joseph Linesch, a pioneering designer who helped landscape Disneyland.

The THUMs islands required exceptional designs, and “the people who were involved at the time were very creative visionaries,” said Frank Komin, executive vice president for southern operations of the California Resources Corporation (CRC), owner of the islands.

About 80 percent of the company’s properties would overlie the Wilmington oilfield, according to CRC, noting that from 2003 to 2018, CRC operations generated over $5.2 billion in revenues, taxes and fees for the City of Long Beach and the state.

THUMS Island White, named for Col. Edward White II, the first American to walk in space, who died in 1967 along with NASA astronauts “Gus” Grissom and Roger B. Chaffee. A fourth island was named for NASA test pilot Ted Freeman, who in 1963 was the first fatality among the astronauts. Photo courtesy UCLA Library.

“Even today, those islands are viewed as one of the most innovative oil field designs in the world,” CRC executive Komin declared in a 2015 Long Beach Business Journal article. “The islands have grown to become icons in which the City of Long Beach takes a great deal of pride.”

The Journal explained that 640,000 tons of boulders, some as large as five tons, were mined and placed to build up the perimeters of the islands. “Concrete facades constructed for aesthetic purposes also divert industrial noise away from nearby residents,” the article added. For more noise abatement, electricity has provided nearly all the power for the islands.

The THUMS aesthetic integration of 175-foot derricks and production structures has been described by the Los Angeles Times as, “part Disney, part Jetsons, part Swiss Family Robinson.”

_______________________

Recommended Reading: An Ocean of Oil: A Century of Political Struggle over Petroleum Off the California Coast (1998); Black Gold in California: The Story of California Petroleum Industry  (2016); Early California Oil: A Photographic History, 1865-1940

(2016); Early California Oil: A Photographic History, 1865-1940 (1985). Your Amazon purchases benefit the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

(1985). Your Amazon purchases benefit the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

_______________________

The American Oil & Gas Historical Society (AOGHS) preserves U.S. petroleum history. Become an AOGHS annual supporting member and help maintain this energy education website and expand historical research. For more information, contact bawells@aoghs.org. Copyright © 2023 Bruce A. Wells. All rights reserved.

Citation Information – Article Title: “THUMS – California’s Hidden Oil Islands.” Authors: B.A. Wells and K.L. Wells. Website Name: American Oil & Gas Historical Society. URL: https://aoghs.org/technology/thums-california-hidden-oil-islands. Last Updated: February 23, 2024. Original Published Date: March 8, 2018.

by Bruce Wells | Jan 28, 2024 | Offshore History

Post-WWII offshore technologies advanced petroleum exploration and production.

Following World War II, the U.S. offshore oil and natural gas industry achieved an important technological milestone in the Gulf of Mexico when Kerr-McGee drilled the first well out of sight of land.

The Kerr-McGee Kermac No. 16 platform began drilling 10 miles from the Louisiana shore on September 10, 1947, in continental shelf waters just 20 feet deep. With the season’s biggest hurricane arriving a week later, the experimental platform constructed by Brown & Root withstood 140 mph winds — another of its contributions to offshore technology.

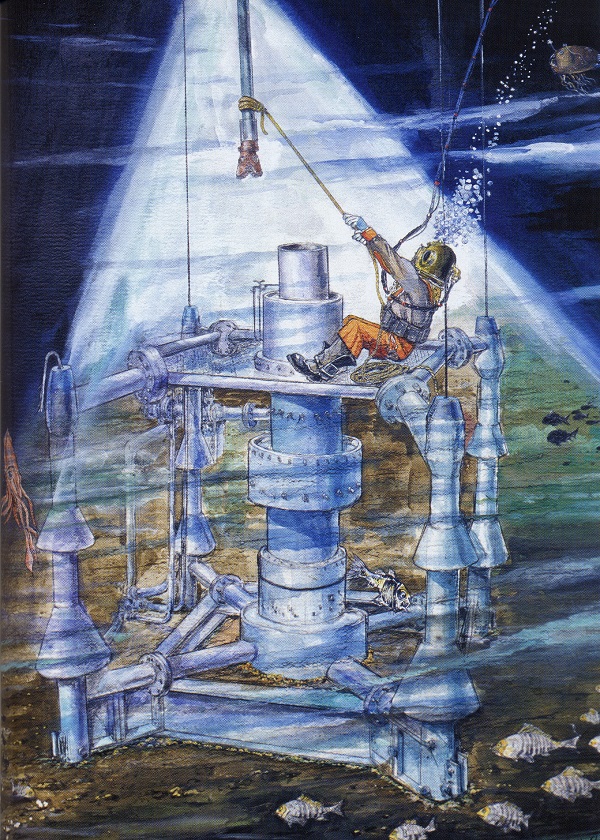

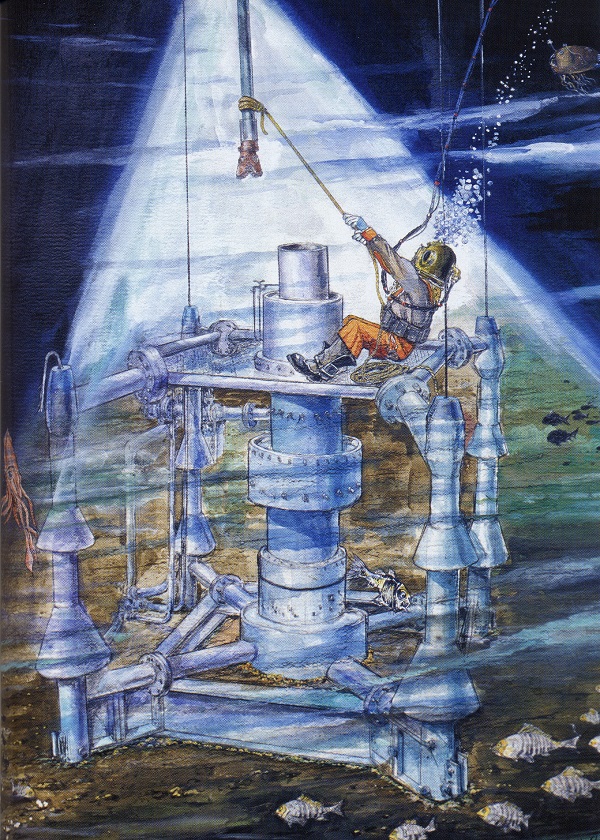

“Stabbing in,” once a deadly hazard for offshore divers, has been replaced with technologies like remotely operated vehicles. Painting by Clyde Olcott from the 2007 book, “The History of Oilfield Diving: An Industrial Adventure,” by Christopher Swann.

The pursuit of offshore oil demanded technological innovation as exploration led to deeper and more inhospitable waters. Offshore divers faced new challenges, including one hazard called “stabbing in” a drill bit at the well.

“Because re-inserting a drill pipe from a moving, heaving barge into the subsea wellhead was a difficult maneuver, each time a worn bit had to be replaced, a diver had to be called,” noted Underwater magazine in a May 2000 article.

“The hard-hat diver effected the ‘stab-in’ by straddling the top of the 24-inch hole between his legs, physically pulling the drill string over the target and at just the right moment instructing the drill floor, 250 feet overhead, to ‘let go.’”

Modern deep sea roughneck technology spares divers this dangerous task, reported Christopher Swann, author of The History of Oilfield Diving, published in 2007. Instead of air, divers began breathing mixtures of helium and oxygen during deep descents and carefully managed decompression ascents.

Swann’s 2007 book includes a painting by Clyde Olcott showing a diver guiding a drill pipe into the wellhead — “stabbing in.”

As an illustrator of pioneering underwater operations, Olcott (1927 – 2009) produced accurate images of commercial divers at work. His artwork documented diving technologies, beginning in the late 1950s at Santa Barbara, California, including oxygen-helium diving.

With many diving companies originating on the U.S. West Coast, Olcott’s illustrations have appeared worldwide in technical manuals, advertisements, company brochures — and as art on boardroom walls. His artwork for company presentations often introduced new offshore diving concepts, according to Leslie Leaney, a past president of the Historical Divers Society.

“When future historians want to review what was happening underwater during the pioneering days of oilfield diving, Clyde’s paintings will be ‘the picture that is worth a thousand words’,” Leaney noted in the Spring 2009 issue of the Journal of Diving History.

Saturation diving and decompression chambers were developed by the offshore industry to further increase bottom times and improve safety. With deep saturation diving, every 100 feet of depth required 24 hours of decompression and like today, time was money.

The extreme cold of deep water prompted Taylor Diving & Salvage of Belle Chasse, Louisiana, to adapt space suits designed for Nasa astronaut John Glenn to deep sea diving. Hot water pumped down from the surface and through dive-suit tubing extended bottom times.

Deep sea diving companies adapted space suits designed for astronaut John Glenn in Friendship 7 capsule. Photo courtesy NASA.

Taylor also developed an underwater welding habitat pressurized with nitrogen that greatly facilitated the critical business of laying pipeline, tie-ins and repairs.

In 1948, Shell Oil Company and others pioneered the use of underwater television cameras for survey, inspection, and repair work. The Navy also developed deep sea technologies for submarine rescue. Technologies for underwater robots began to evolve.

By the early 1960s, Hughes Aircraft Company had built the first marine “Manipulator Operated Robot” — MOBOT — for Shell Oil Company. The underwater robot used sonar and television cameras for navigation, propellers for propulsion, and an umbilical cable for control. For more about MOBOT, see ROV – Swimming Socket Wrench.

Despite state-of-the-art robotics, offshore petroleum industry and scientific needs for manned deep sea diving continued.

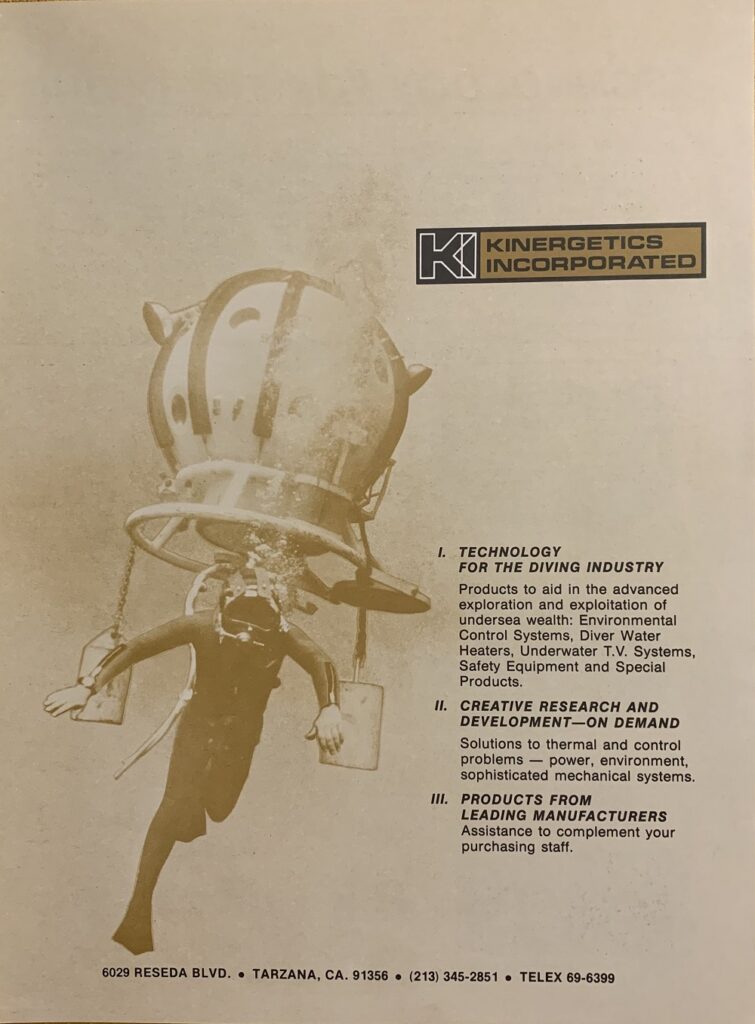

Diving technologies evolved to meet petroleum industry needs as drilling depths increased in the 1960s. Ad image courtesy JoAnn Cowans.

Hughes Aircraft engineer Ken Cowen in the 1960s analyzed heat domes of missiles traveling at speeds of up to Mach 3. After more cryogenics work related to heat transfer, he established offshore technology company Kinergetics, where he worked with NASA astronaut-turned-aquanaut Scott Carpenter.

As Cowans’ wife JoAnn painted award-winning oilfield scenes of Southern California (see Petroleum & Oilfield Artists), he patented sub-sea products, including diving safety equipment. The Kinergetics “Stranded Bell Diver Survival System” provided life-prolonging survival in a cold hyperbolic environment.

Early Technologies and CUSS

Along California’s coastline, the need for divers (man or mechanical) had begun as petroleum exploration followed known oilfields offshore. Drilling contractors developed special platforms and constructed drilling piers, but productive fields extended into Pacific Ocean depths far from the shoreline.

Until remotely operating devices were invented, drilling in depths of 200 feet and beyond required the endurance and capabilities of experienced hard-hat divers.

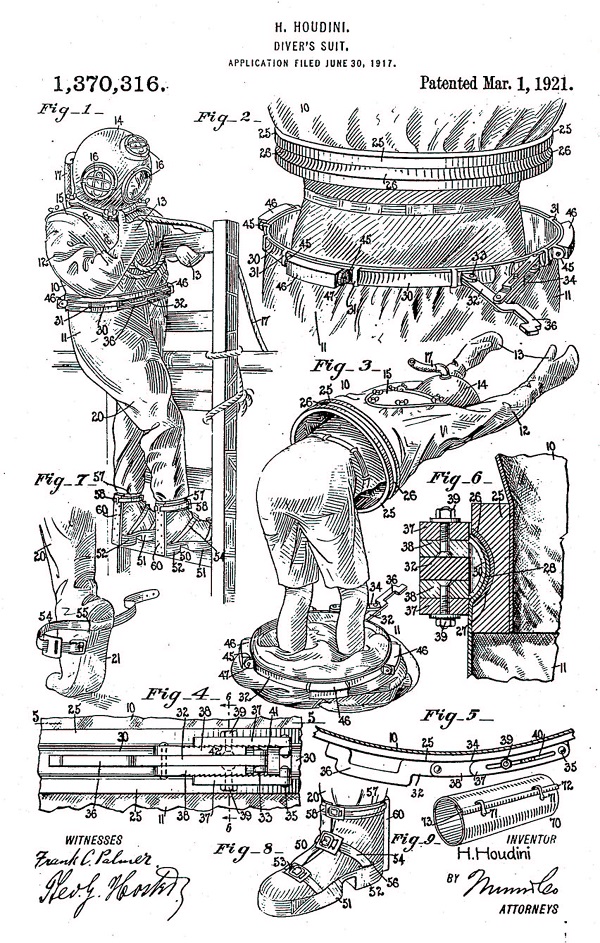

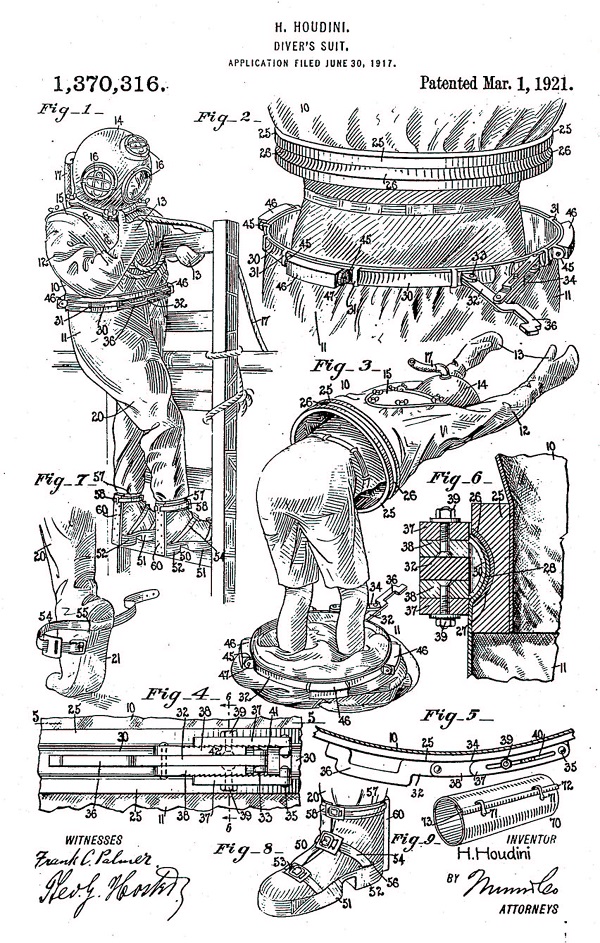

The dangers of deep sea diving prompted famed magician and escape artist Harry Houdini to patent his 1921 invention of a quick release mechanism to help divers exit their cumbersome suits.

Production methods and equipment would demand new technologies invented by offshore pioneers — including a diver’s suit patented by escape artist Harry Houdini.

In the early days of West Coast petroleum exploration, Albacore divers found new opportunities around numerous California oil seeps, especially at Santa Barbara. The geologic region there has remained active because of the movement of the San Andreas and other faults. The numerous oil seeps led to discovery of the Los Angeles City oilfield in 1892.

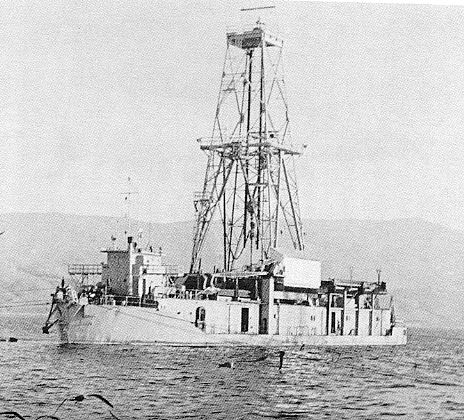

Faced with developing new and expensive offshore technologies, in 1948, Continental Oil Company (today’s Conoco-Phillips) partnered with Union Oil, Shell Oil and Superior Oil in a joint venture – using company initials to form the CUSS Group.

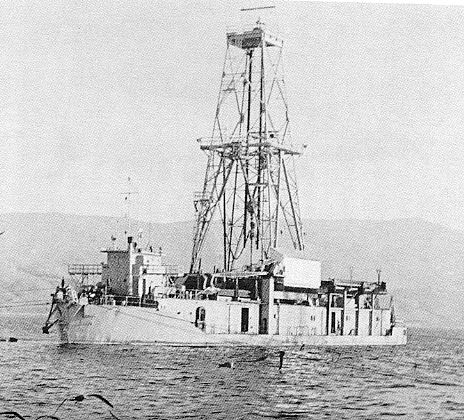

The CUSS objective was to pursue deep-water drilling and for the first time develop motion-restricted drilling ships. Experiments began with Submarex, a modified U.S. Navy submarine chaser, followed in 1956 by the CUSS I, a converted World War II barge 260 feet long with a 48 -foot beam.

CUSS I pioneered the use of underwater television cameras to assist in survey, inspection and repair work. In 1965, the vessel drilled a well in 635 feet of water, setting and cementing multiple strings of casing without using divers.

However, most offshore petroleum work still required the skills of traditional hard-hat divers.

Highly advanced at the time, CUSS I used four steering propellers and six mooring buoys to hold the ship in position. During this same period, the U.S. Navy was developing its own deep sea technology for both submarine rescue and Cold War antisubmarine purposes.

Tethered to a mother ship by umbilical cables, remotely operated underwater vehicles (ROVs) in 1963 helped find the the nuclear attack submarine USS Thresher, which had sunk with all hands during deep a diving test. The recovery vessel included a 95-foot derrick amidships over a diamond shaped sea opening, still known today as a “moon pool.”

Offshore Engineering

Tapping into the prolific oilfields that extended offshore from popular California beaches brought strict state regulations.

“With leasing from the state of California to explore and produce oil and gas, well control and the ability to run multiple strings of casing became mandatory and required a totally new, unproven technology,” explained the Society of Petroleum Engineers (SPE) in a 1987 study.

Built in 1956 by a partnership of four companies, Continental, Union, Shell, and Superior, the offshore drilling vessel CUSS 1 was a converted World War II barge.

“The first floating drilling rig to use subsea well control was the Western Explorer owned by Chevron, which spudded its first well in 1955 in the Santa Barbara Channel,” the society noted.

Other offshore drilling rigs and production platform innovations followed. Petroleum engineers developed technologies to allow deep drilling in the roughest weather. But even with advanced undersea robotics, the petroleum industry has continued to rely on manned diving.

Modern atmospheric diving systems enclose the operator at one-atmosphere pressure, regardless of depth, thereby eliminating the necessity for decompression.

The modern deep sea “Hardsuit 2000” includes 16 rotary joints and two thrusters for mobility.

The “Hardsuit 2000” with 16 rotary joints and two thrusters for mobility, bears little resemblance to its traditional hard-hat ancestors. The suit can operate at depths up to 2,000 feet and remain for six hours on the bottom with no decompression required.

Women Pioneers

As the offshore petroleum industry continued to expand worldwide, it needed all the skilled workers it could find — of any gender. Journalist and professional landman Rebecca Ponton in 2019 published a collection of personal accounts from women who challenged oil industry stereotypes.

Ponton interviewed a diverse collection of energy professionals for Breaking the Gas Ceiling: Women in the Offshore Oil and Gas Industry, preserving the underrecognized accomplishments of “WOW — Women on Water,” her introductory chapter’s title.

Among the stories are experiences of an offshore helicopter pilot, logistics superintendent, photographer, federal agency director, and mechanical and chemical engineers. Among her sources, Ponton interviewed Marni Zabarski, who in 2001 became the first female saturation diver in the Gulf of Mexico.

Offshore safety pioneer Margaret McMillan in the late 1980s helped establish the Marine Survival Training Center at the University of Louisiana at Lafayette. In 2004, McMillan was the first woman to be inducted into the Houston-based Oilfield Energy Center’s Hall of Fame.

Pursuit of U.S. offshore oil and natural gas has continued to generate advanced technologies. Innovators and underwater oil patch roughnecks continue to push both science and offshore industry to new, deeper frontiers.

By 2011, more than 4,500 offshore petroleum platforms supplied 25 percent of the United States’ production of natural gas and 10 percent of its oil. An industry-government partnership has used offshore structures no longer producing to form the world’s largest artificial reef complex (see Rigs to Reefs).

Learn more about the evolution of offshore exploration and production technologies in Offshore Petroleum History.

_______________________

Recommended Reading: Diving & ROV: Commercial Diving offshore (2021); Breaking the Gas Ceiling: Women in the Offshore Oil and Gas Industry (2019); The History of Oilfield Diving: An Industrial Adventure (2007); The Offshore Imperative: Shell Oil’s Search for Petroleum in Postwar America (2009); Offshore Pioneers: Brown & Root and the History of Offshore Oil and Gas

(2009); Offshore Pioneers: Brown & Root and the History of Offshore Oil and Gas (1997). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

(1997). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

_______________________

The American Oil & Gas Historical Society (AOGHS) preserves U.S. petroleum history. Become an AOGHS annual supporting member and help maintain this energy education website and expand historical research. For more information, contact bawells@aoghs.org. Copyright © 2024 Bruce A. Wells. All rights reserved.

Citation Information – Article Title: “Deep Sea Roughnecks.” Authors: B.A. Wells and K.L. Wells. Website Name: American Oil & Gas Historical Society. URL: https://aoghs.org/offshore-history/deep-sea-roughnecks. Last Updated: February 1, 2024. Original Published Date: January 13, 2011.

by Bruce Wells | Jan 27, 2024 | Petroleum History Almanac

Advanced 1970s offshore technologies, Howard Hughes, and the CIA project to raise a lost Soviet submarine.

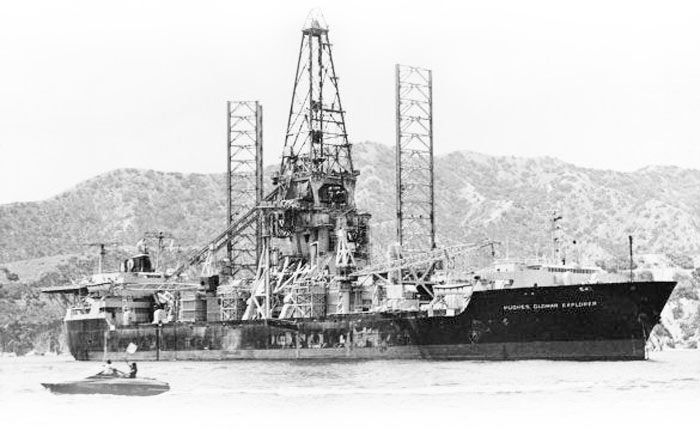

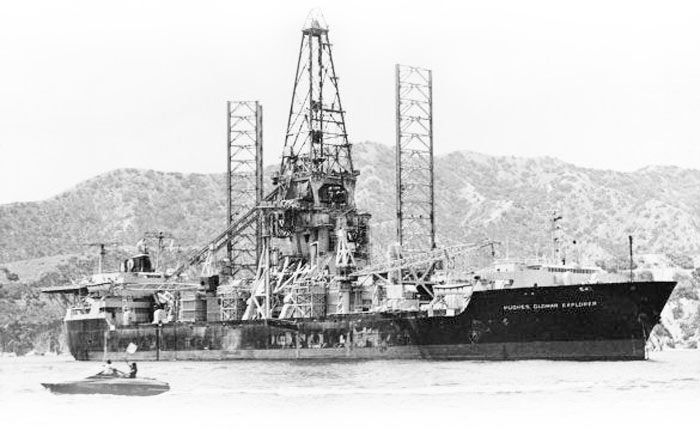

The Glomar Explorer left behind two remarkable offshore exploration histories — a clandestine submarine recovery vessel and the world’s most advanced deep water drill ship for the petroleum industry. The CIA’s former “ocean mining” vessel ended its offshore career in a Chinese scrap yard in 2015.

Considered the pioneer of modern drill ships, the Glomar Explorer was decades ahead of its time working at extreme depths for the U.S. offshore petroleum industry. Relaunched in 1998 as an offshore technological phenomenon, the original Glomar Explorer had been constructed as a top-secret project of the Central Intelligence Agency.

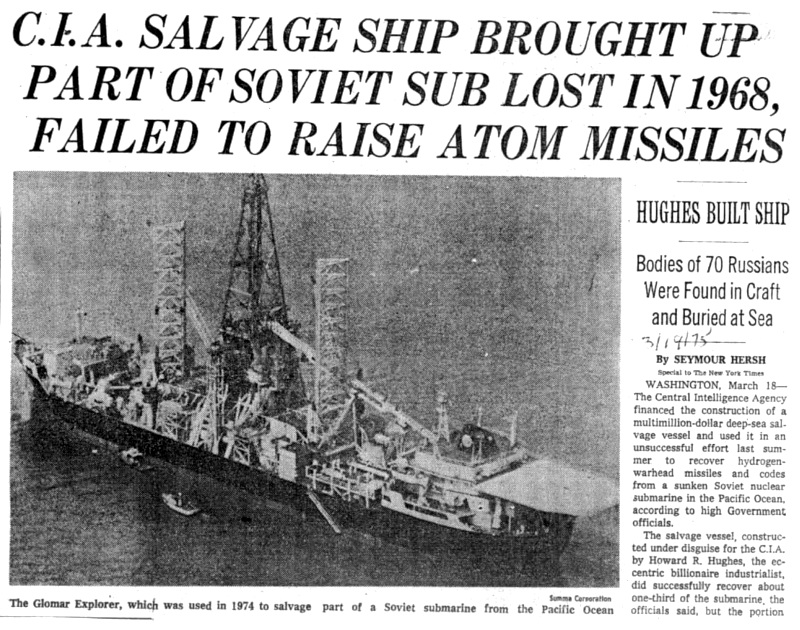

The Central Intelligence Agency’s Hughes Glomar Explorer, a custom-built “magnesium mining vessel,” in 1974 recovered part of a Soviet submarine that had sunk off Hawaii in 1968. Photo courtesy American Society of Mechanical Engineers.

CIA Project Azorian began soon after the U.S.S.R. ballistic missile submarine K-129 mysteriously sank somewhere in the deep Pacific Ocean northeast of Hawaii on March 8, 1968. The wreckage of the lost sub could never be found — or so it seemed.

Unknown to the Soviets, sophisticated U.S. Navy sonar technology would locate the K-129 on the seabed at a depth of 16,500 feet. But a salvage operation more than three miles deep was impossible with any known technology (see ROV – Swimming Socket Wrench).

The K-129 sinking presented the CIA with such an espionage opportunity that the agency convinced President Richard Nixon to approve a secret operation to attempt raising the vessel — intact — from the ocean floor.

Secretive billionaire Howard Hughes Jr. of Hughes Tool Company joined the mission, code-named Project Azorian (mistakenly called Project Jennifer in news media accounts).

The recovery effort would involve years of deception: Deep ocean mining would be the cover story for construction of the Hughes Glomar Explorer.

Hughes and Ocean Mining

Scientists and venture capitalists had long seen potential in ocean mining, but when Hughes appeared to take on the challenge, the world took notice. The well-publicized plan described harvesting magnesium nodules from record depths with a custom-built ship that would push engineering technology to new limits, typical of Hughes’ style. The story spread.

But from concept to launch, the Hughes Glomar Explorer really had only one purpose: raise the sunken Soviet Golf-II class submarine from 1968 – and any ballistic missiles. In 1972, construction began in a Delaware River dry-dock south of Philadelphia. The $350 million (about $2.37 billion in 2023), Hughes’ high-tech ship was ostensibly built to mine the sea floor.

On August 8, 1974, the “magnesium mining vessel” secretly raised part of the 2,000-ton K-129 through a hidden well opening in the hull and a “claw” of mechanically articulated fingers that used sea water as a hydraulic fluid. News about Project Azorian leaked within six months.

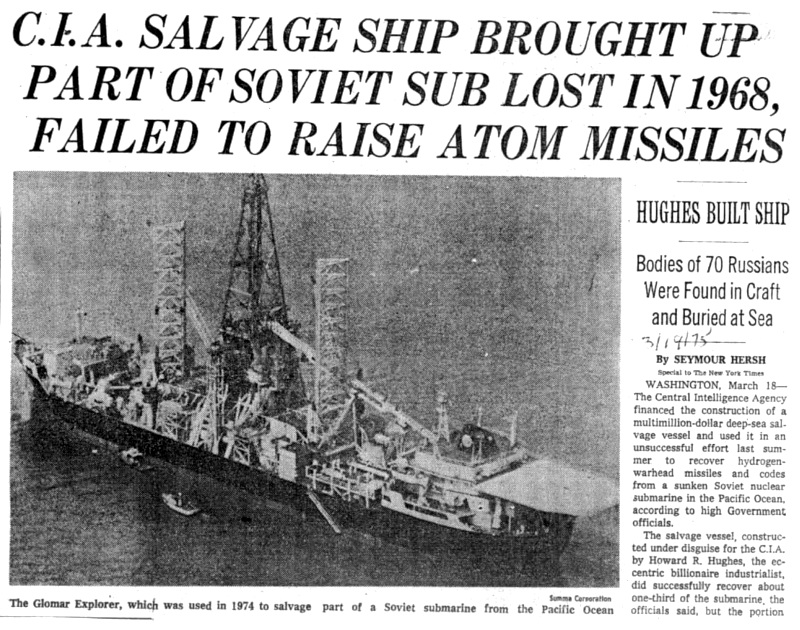

On February 7, 1974, the Los Angeles Times broke the story: “CIA Salvage Ship Brought Up Part Of Soviet Sub Lost In 1968, Failed To Raise Atom Missiles.”

The L.A. Times article by Pulitzer-Prize winning journalist Seymour Hersh ended the high-tech vessel’s spying career. The government transferred Hughes Glomar Explorer to the Navy in 1976 for an extensive $2 million preparation for storage in dry dock. With its CIA days over, Hughes Glomar Explorer spent almost two decades mothballed at Suisun Bay, California.

Seymour Hersh of the Los Angeles Times revealed the clandestine project on February 7, 1974. An investigative reporter, he had won the Pulitzer Prize in 1970 for exposing the My Lai massacre.

Pioneer Drill Ship

London-based Global Marine had converted the CIA vessel for commercial use. The company hired Electronic Power Design of Houston, Texas, to work on the advanced electrical system. After almost 20 years in storage, condition of equipment inside the ship surprised Electronic Power Design CEO John Janik.

“Everything was just as the CIA had left it,” Janik explained, “down to the bowls on the counter and the knives hanging in the kitchen. Even though all the systems were intact, this was by no means an ordinary ship.”

Janik noted in 2015 for The Maritime Executive that his company’s retrofit was “a tough job because the ship’s wiring was unlike anything we had ever seen before,” although preservation had been helped by nitrogen pumped into the ship’s interior for two decades.

Conversion work later included a Mobile, Alabama, shipyard adding a derrick, drilling equipment, and 11 positioning thrusters capable of a combined 35,200 horsepower.

Completed in 1998 as the world’s largest drillship, Glomar Explorer began a long-term lease from the U.S. Navy to Global Marine Drilling for $1 million per year.

The advanced drilling ship spent the next 17 years working in deep-water sites around the globe, including Africa’s Nigerian delta, the Black Sea, offshore Angola, Indonesia, Malta, Singapore, and Malaysia.

Following a series of corporate mergers, Glomar Explorer became part of the largest offshore drilling contractor, the Swiss company Transocean Ltd. When it entered that company’s fleet, the ship was renamed GSF Explorer, and in 2013 was re-flagged from Houston to the South Pacific’s Port Vila in Vanuatu.

The formerly top secret CIA vessel Glomar Explorer began a record-setting career in 1998 as a technologically advanced deep water drill ship. Photo courtesy American Society of Mechanical Engineers.

When GSF Explorer arrived at the Chinese ship breaker’s yard in 2015, many offshore industry trade publications took notice of the ship’s demise after years of exceptional deep drilling service. The ship was “decades ahead of its time and the pioneer of all modern drill ships,” declared the Electronic Power Design CEO in The Maritime Executive article.

“It broke all the records for working at unimaginable depths and should be remembered as a technological phenomenon,” Janik concluded.

Soon after the former Glomar Explorer was sold for scrap, Tom Speight of the engineering firm O’Reilly, Talbot & Okun, reflected in a company post, “This is a shame, not only because of the ship’s nearly unbelievable history, but also because in 2006 the American Society of Mechanical Engineers designated this technologically remarkable ship a historic mechanical engineering landmark.”

The ASME award ceremony, which took place on July 20, 2006, in Houston, included members of the original engineering team and ship’s crew among the attendees. Past President Keith Thayer noted the important contributions the ship made to the development of mechanical engineering and innovations in offshore drilling technology.

The historic ship’s name will be forever be linked to the ship’s CIA brief service during the Cold War. For many veteran journalists, the agency’s chronic response to inquiries, “We can neither confirm nor deny,” is still known as the “Glomar response.”

_______________________

Recommended Reading: The CIA’s Greatest Covert Operation: Inside the Daring Mission to Recover a Nuclear-Armed Soviet Sub (2012); Project Azorian: The CIA and the Raising of the K-129 (2012). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

_______________________

The American Oil & Gas Historical Society (AOGHS) preserves U.S. petroleum history. Become an AOGHS annual supporting member and help maintain this energy education website and expand historical research. For more information, contact bawells@aoghs.org. Copyright © 2024 Bruce A. Wells. All rights reserved.

Citation Information – Article Title: “Secret Offshore History of Drill Ship Glomar Explorer.” Authors: B.A. Wells and K.L. Wells. Website Name: American Oil & Gas Historical Society. URL: https://aoghs.org/oil-almanac/secret-offshore-history-of-the-glomar-explorer. Last Updated: January 25, 2024. Original Published Date: February 8, 2020.

by Bruce Wells | Apr 19, 2023 | AOGHS Newsletter

(2016); Early California Oil: A Photographic History, 1865-1940

(1985). Your Amazon purchases benefit the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.