by Bruce Wells | Nov 6, 2024 | Offshore History

The U.S. offshore drilling for oil began in the late-19th century on lakes and at the ends of Pacific Ocean piers. Until an innovative Kerr-McGee drilling platform in 1947, no offshore drilling company had ever risked drilling beyond the sight of land.

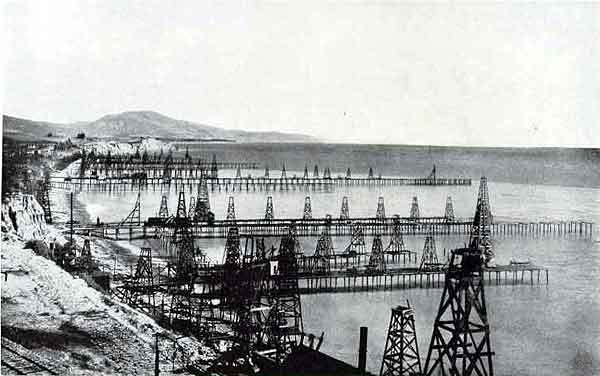

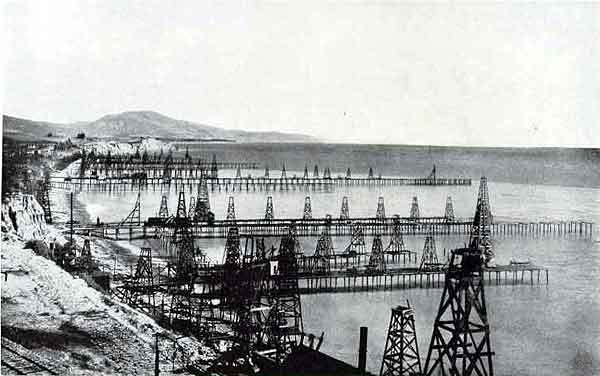

Many of the earliest offshore oil wells were drilled from piers at Summerland in Santa Barbara County, California. Circa 1901 photo by G.H. Eldridge courtesy National Oceanic & Atmospheric Administration.

In 1896, as enterprising businessmen pursued California’s prolific Summerland oilfield all the way to the beach, the lure of offshore production enticed Henry L. Williams and his associates to build a pier 300 feet out into the Pacific — and mount a standard cable-tool rig on it. (more…)

by Bruce Wells | Jul 28, 2024 | Offshore History, Petroleum in War

Shipwrecks revealed during routine scan of Gulf of Mexico seabed for new pipelines.

During World War II, U-boats prowled the Gulf of Mexico to disrupt the flow of oil carried by tankers departing ports in Louisiana and Texas. Sixty years later, seabed surveys found U-166 — and its last victim.

Petroleum exploration and production companies operating in the Gulf of Mexico’s outer continental shelf routinely provide government scientists with sonar data for areas with potential archaeological value. (more…)

by Bruce Wells | Jun 7, 2024 | Offshore History

Mr. Charlie originated with Navy World War II veteran Alden “Doc” LaBorde, who believed a self-sufficient oil rig could be placed on a barge for deeper offshore drilling. LaBorde’s Mr. Charlie — the world’s first mobile offshore drilling unit (MODU) — has since served as a “glimpse into the past” of the modern energy industry. (more…)

by Bruce Wells | Jun 4, 2024 | Offshore History

America’s offshore petroleum industry began with drilling and production from platforms constructed on lakes in Ohio and Louisiana, and on California oil piers. In Ohio, state geologists reported oil wells drilled on Grand Lake as early as 1891. Dozens of wells on Louisiana’s Caddo Lake also produced oil in 1911.

By 1897, Henry Williams had successfully pursued the giant Summerland, California, oilfield to the scenic cliff side beaches of Santa Barbara.

California Oil Piers

With reports of “tar balls” on the beaches from natural offshore oil seeps, Williams recognized that the highly productive field extended into the Pacific Ocean. He and his associates constructed a 300 foot pier, mounted a cable-tool derrick, and began drilling. (more…)

by Bruce Wells | Apr 25, 2024 | Offshore History

Thomas Rowland’s Continental Iron Works produced gas fittings, welded oil storage tanks, and a famous ironclad.

The origins of the modern offshore oil exploration and production industry must include the 1869 offshore rig patent “Rock Drill” design of a skilled New York engineer.

On May 4, 1869, Thomas Fitch Rowland, owner of Continental Iron Works in Greenpoint, New York, received a U.S. patent for an unusual “submarine drilling apparatus.” His patent (No. 89,794) for a fixed, offshore drilling platform came just 10 years after America’s first commercial oil discovery in Titusville, Pennsylvania.

(more…)

by Bruce Wells | Mar 1, 2024 | Offshore History

Thousands of offshore petroleum structures provide energy — and marine habitats.

Offshore petroleum platforms act as artificial reefs, creating important marine habitats, according to scientists. Beginning with an Exxon experimental subsea structure in 1979, the U.S. government’s “Rigs to Reefs” program established the largest artificial habitat in the world.

The Gulf of Mexico, both onshore and offshore, has continued to be a key contributor to U.S. oil and natural gas resources and energy infrastructure. Federal offshore oil production in 2023 accounted for 15 percent of total U.S. crude oil and five percent of natural gas production, according to the U.S. Energy Information Administration (EIA).

Offshore platforms make good artificial reefs. The open design attracts fish — and divers — where they can swim easily through the circulating water. Photo courtesy U.S. Bureau of Safety and Environmental Enforcement.

(more…)