“Conundrums” spooled petroleum pipelines across the English Channel after D-Day.

Secret pipelines unwound from massive spools to reach French ports and transport vital oil across the English Channel after the June 6, 1944, D-Day landings.

Wartime planners knew that following the Normandy invasion, Allied forces would need vast quantities of petroleum to continue the advance into Europe. The Allies also knew any tankers trying to reach French ports would be vulnerable to Luftwaffe attacks. A secret plan relied on new undersea pipeline technologies.

To prevent fuel shortages from stalling the invasion, the top-secret “Operation PLUTO” — Pipe Line Under The Ocean — became a key Allied strategy. It would fuel victory with oil production from the U.S. petroleum industry.

The Royal Air Force in 1944 produced a film including Disney’s dog Pluto and a “conundrum.” Image courtesy Imperial War Museum.

Although by 1942 the industry had laid thousands of pipe miles across all manner of terrain, to span the English Channel would require an unprecedented leap in technology. The channel was deep, the French ports distant, and the hazards unpredictable. In great secrecy, two approaches were developed.

Undersea Pipeline Technology

The first PLUTO system required a new kind of pipe that looked more like an undersea communications cable than an oil pipeline. It exploited existing subsea cable technology, but instead of a bundle of wiring at its core, a three-inch flexible lead pipe would carry fuel.

Each mile of this new pipe would use over 46 tons of lead, steel tape and armored wire – crossing almost 70 miles from Isle of Wight to Cherbourg.

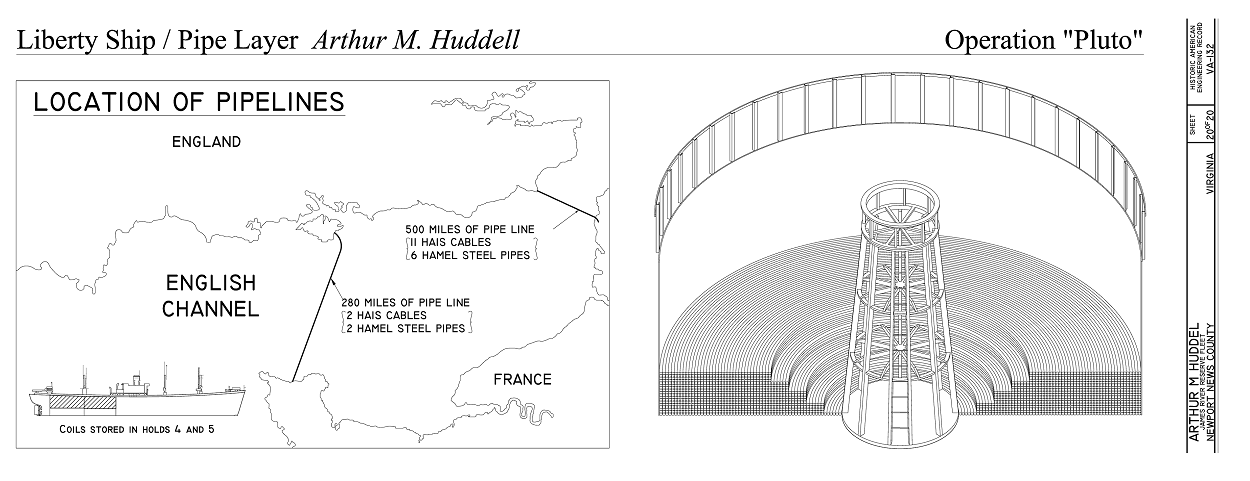

Modified to carry pipelines for Operation PLUTO, the Liberty-class ship Arthur M. Huddell later laid communication cables and a secret sound surveillance system. U.S. Maritime Administration drawing courtesy Library of Congress.

Unique ships would be needed to lay this new pipe under the channel. No existing communications cable-laying ship could do it.

Described as the workhorses of World War II, Liberty ships included the Arthur M. Huddell, modified to carry pipelines for use in Operation PLUTO. The vessel later laid communication cables for the American Telephone and Telegraph Company (ATT) and the Cold War’s secret Sound Surveillance System (SOSUS).

A civilian passenger vessel, London, was the first to be modified to accommodate a huge spool around which the new pipe would be coiled. The first pipeline from Isle of Wight to Cherbourg was laid on August 14, 1944, with another to follow.

Floating Conundrums

An alternative approach proved even more successful. This method used three-inch steel pipe, which had proven to be flexible and durable in the oilfields of Iraq and Burma. The steel pipe could be wrapped around giant drums.

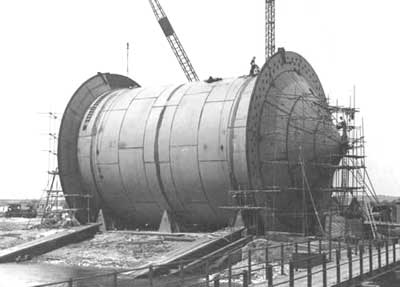

Pipeline was wound onto enormous floating “conundrums” designed to spool off the pipe when towed. As the spools unwound, the pipe settled to the bottom of the English Channel.

Welders assembled 20-foot sections of pipe into 4,000-foot lengths. The pipeline was wound onto enormous floating “conundrums” that were designed to spool off the pipe when towed.

Gen. Dwight Eisenhower declared Operation PLUTO, “Second in daring only to the artificial ‘Mulberry’ harbors”

These deployment systems weighed 1,600 tons each and were pulled by three tugboats from the British site at Dungeness to the French port of Boulogne, 31 miles away. As the spools unwound, the pipe settled to the bottom of the English Channel.

Ultimately, using both pipelaying methods, 17 pipelines supplied thousands of gallons of fuel to Boulogne. By March 1945, one million gallons of fuel were being delivered each day and Allied success was assured.

Among the collections of the Imperial War Museums is a secret Operation PLUTO film produced by the Royal Air Force in 1944, “with detailed coverage of the network of pipes and pumping stations on the English coast, the manufacturing process of the main types of undersea pipeline used and coverage of various sea trials of pipeline laying equipment.”

An earlier project to fuel the Allied war effort led to the longest U.S. pipeline construction project ever undertaken – two lines spanning 1,200 miles from Texas oilfields to eastern refineries (see Big Inch Pipelines of WW II).

The end of World War II brought a hiatus to development of undersea pipeline technology. In the shallow Gulf of Mexico, the petroleum industry continued laying pipe by welding individual lengths of oil and gas pipe together aboard barges. The process required frequent halts for new sections to be added.

But by the 1960s, the World War II engineering feat of reel-laying began to reappear in the offshore industry. Operation PLUTO precedents can be seen in modern pipe-laying vessels unrolling coiled pipe to remarkable lengths.

The massive, towed drums have receded into history. Coiled pipe reels now ride aboard specialized vessels — constructing a subsea infrastructure that safely connects oil and natural gas production platforms with refineries on shore.

The MV Solitaire set a world record in 2007 for an ultra-deep pipeline installation that reached depths of 9,100 feet.

In 2007, the Mitsubishi-built MV Solotaire laid pipe to a record-setting depth of 9,100 feet. Capable of holding more than 22,000 tons of 60-inch diameter pipe, the ship can lay down almost six miles in a day.

D-Day Jack-Up Rigs: Mulberrys

“Second in daring only to the Mulberry Harbours, was PLUTO.” – Gen. Dwight D. Eisenhower.

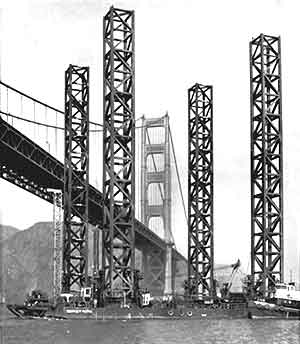

The D-Day logistics of supplying troops put ashore on Omaha and Gold beaches in June 1944 included highly classified construction of artificial harbors, codenamed Mulberrys – employing the ancestors of today’s jack-up rigs.

Mulberrys used barges 200 feet long and 60 feet wide – each with four retractable 60-foot pylons to provide platforms to support floating causeways that extended to the beaches. Tons of supplies and equipment came ashore in the massive effort. Offshore drilling companies adopted this jack-up pier technology after the war.

San Francisco, December 15, 1958: “Seemingly towering above the Golden Gate Bridge, this ungainly barge with towering legs proceeds on its way towards the open sea. The towers, which will eventually serve as legs reaching to the ocean floor, were raised again after passing the bridge.”

Offshore exploration advanced rapidly after Kerr McGee’s 1947 success with the first producing well out of sight of land, the KerrMac No. 16, which stood in only 20 feet of water in the Gulf of Mexico. Surplus World War II tenders supplied these drilling operations.

Within ten years, in addition to tender-serviced platforms in shallow waters, jack-up rigs equipped with much larger pylons were operating successfully to depths of more than 150 feet.

Pylons grew in length from the original 60 feet to almost 300 feet. Col. Leon B. DeLong of the U.S. Army Corps of Engineers continued developing D-Day’s jack-up rig concept. After the war, DeLong designed platforms that began operating as Modular Offshore Drilling Units (MODU) miles from shore (see Offshore Oil History).

Learn about another top-secret World War II “English Project” in Roughnecks of Sherwood Forest.

_______________________

Recommended Reading: Code Name MULBERRY: The Planning Building and Operation of the Normandy Harbours (1977). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

_______________________

The American Oil & Gas Historical Society (AOGHS) preserves U.S. petroleum history. Please become an AOGHS annual supporter and help maintain this energy education website and expand historical research. For more information, contact bawells@aoghs.org. © 2025 Bruce A. Wells.

Citation Information – Article Title: “PLUTO, Secret Pipelines of WW II.” Authors: B.A. Wells and K.L. Wells. Website Name: American Oil & Gas Historical Society. URL: https://aoghs.org/petroleum-in-war/secret-pipelines. Last Updated: June 7, 2025. Original Published Date: February 3, 2010.