by Bruce Wells | Jan 21, 2025 | Offshore History

Post-WWII offshore technologies advanced petroleum exploration and production.

Following World War II, the U.S. offshore oil and natural gas industry achieved an important technological milestone in the Gulf of Mexico when Kerr-McGee drilled the first well out of sight of land.

The Kerr-McGee Kermac No. 16 platform began drilling 10 miles from the Louisiana shore on September 10, 1947, in continental shelf waters just 20 feet deep. With the season’s biggest hurricane arriving a week later, the experimental platform constructed by Brown & Root withstood 140 mph winds — another of its contributions to offshore technology. (more…)

by Bruce Wells | Jan 6, 2025 | Offshore History

As the turn of the century approached, oil producing Ohio wells drilled far out over a reservoir mark the beginning of America’s offshore petroleum industry, according to Mercer County historians.

America’s first offshore drilling once was generally acknowledged to be over Louisiana’s Caddo Lake in 1911 – until researchers in Mercer and Auglaize counties in Ohio said otherwise.

Oil patch sleuths pointed to Mercer County documents recording wells producing oil above the waters of Grand Lake St. Marys at least 20 years before drillers ventured over the waters of Caddo Lake above the giant Caddo-Pine Island field. (more…)

by Bruce Wells | Nov 6, 2024 | Offshore History

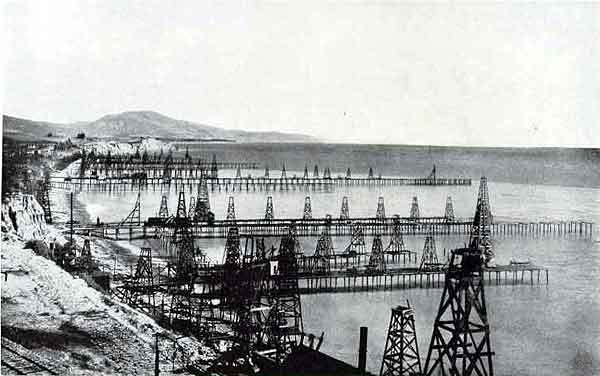

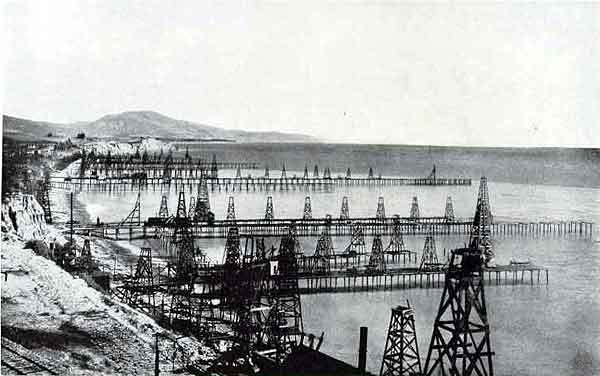

The U.S. offshore drilling for oil began in the late-19th century on lakes and at the ends of Pacific Ocean piers. Until an innovative Kerr-McGee drilling platform in 1947, no offshore drilling company had ever risked drilling beyond the sight of land.

Many of the earliest offshore oil wells were drilled from piers at Summerland in Santa Barbara County, California. Circa 1901 photo by G.H. Eldridge courtesy National Oceanic & Atmospheric Administration.

In 1896, as enterprising businessmen pursued California’s prolific Summerland oilfield all the way to the beach, the lure of offshore production enticed Henry L. Williams and his associates to build a pier 300 feet out into the Pacific — and mount a standard cable-tool rig on it. (more…)

by Bruce Wells | Jul 28, 2024 | Offshore History, Petroleum in War

Shipwrecks revealed during routine scan of Gulf of Mexico seabed for new pipelines.

During World War II, U-boats prowled the Gulf of Mexico to disrupt the flow of oil carried by tankers departing ports in Louisiana and Texas. Sixty years later, seabed surveys found U-166 — and its last victim.

Petroleum exploration and production companies operating in the Gulf of Mexico’s outer continental shelf routinely provide government scientists with sonar data for areas with potential archaeological value. (more…)