by Bruce Wells | Dec 5, 2024 | Petroleum Technology

Government scientists experimented with atomic blasts to fracture natural gas wells.

Project Gasbuggy was the first in a series of Atomic Energy Commission downhole nuclear detonations to release natural gas trapped in shale. This was “fracking” late 1960s style.

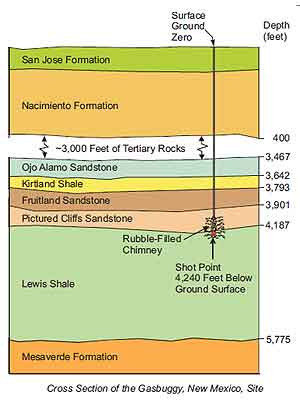

In December 1967, government scientists — exploring the peacetime use of controlled atomic explosions — detonated Gasbuggy, a 29-kiloton nuclear device they had lowered into an experimental well in rural New Mexico. The Hiroshima bomb of 1945 was about 15 kilotons.

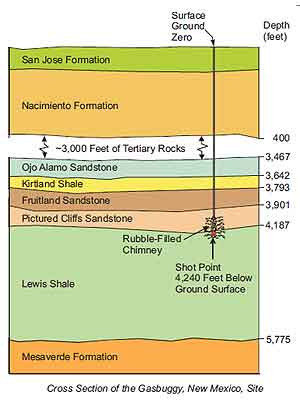

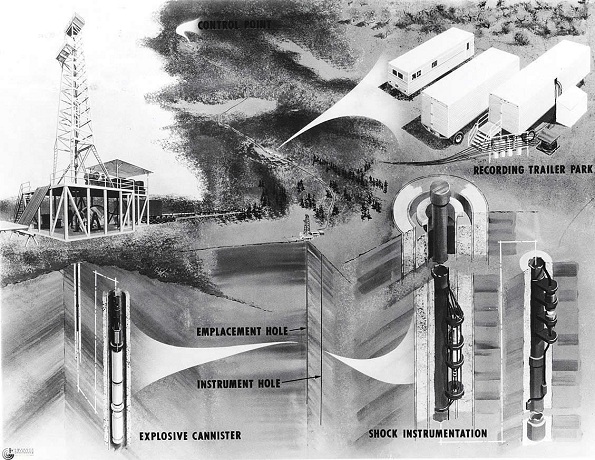

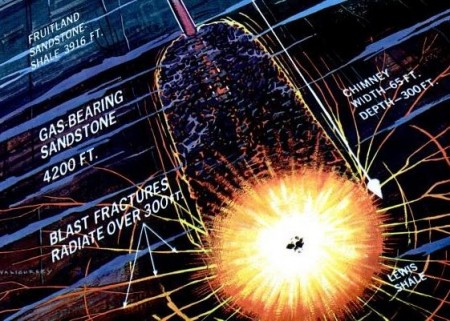

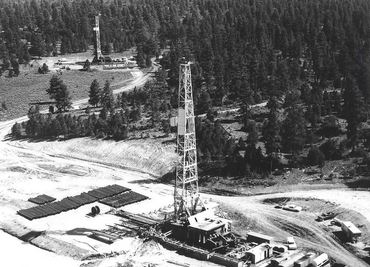

Scientists lowered a 13-foot by 18-inch diameter nuclear device into a New Mexico gas well. The experimental 29-kiloton Project Gasbuggy bomb was detonated at a depth of 4,240 feet. Photo courtesy Los Alamos Lab.

The Project Gasbuggy team included experts from the Atomic Energy Commission, the U.S. Bureau of Mines, and El Paso Natural Gas Company. They sought a new, powerful method for fracturing petroleum-bearing formations.

Near three low-production natural gas wells, the team drilled to a depth of 4,240 feet — and lowered a 13-foot-long by 18-inch-wide nuclear device into the borehole.

Plowshare Program: Peaceful Nukes

The 1967 experimental explosion in New Mexico was part of a wider set of experiments known as Plowshare, a program established by the Atomic Energy Commission in 1957 to explore the constructive use of nuclear explosive devices.

“The reasoning was that the relatively inexpensive energy available from nuclear explosions could prove useful for a wide variety of peaceful purposes,” noted a report later prepared for the U.S. Department of Energy.

From 1961 to 1973, researchers carried out dozens of separate experiments under the Plowshare program — setting off 29 nuclear detonations. Most of the experiments focused on creating craters and canals. Among other goals, it was hoped the Panama Canal could be inexpensively widened.”

In the end, although less dramatic than nuclear excavation, the most promising use for nuclear explosions proved to be for stimulation of natural gas production,” explained the September 2011 government report.

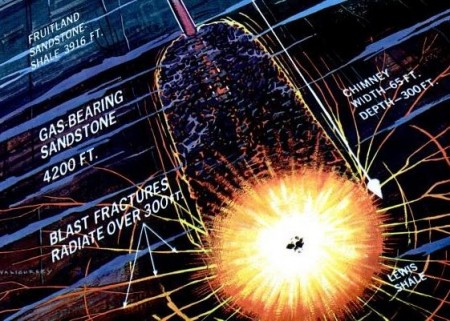

Detonated 60 miles from Farmington in 1967, the first nuclear detonation created a “Rubble Filled Chimney,” producing 295 million cubic feet of natural gas — and deadly Tritium radiation.

Tests, mostly conducted in Nevada, also took place in the petroleum fields of New Mexico and Colorado. Project Gasbuggy was the first of three nuclear fracturing experiments that focused on stimulating natural gas production. Two later tests took place in Colorado.

Atomic Energy Commission scientists worked with experts from the Astral Oil Company of Houston, with engineering support from CER Geonuclear Corporation of Las Vegas.

The experimental wells, which required custom drill bits to meet the hole diameter and narrow hole deviation requirements, were drilled by Denver-based Signal Drilling Company or its affiliate, Superior Drilling Company.

Projects Rulison and Rio Blanco

In 1969, Project Rulison, the second of the three nuclear well stimulation projects, blasted a natural gas well near Rulison, Colorado. Scientists detonated a 43-kiloton nuclear device almost 8,500 feet underground to produce commercially viable amounts of natural gas.

In 1973, another fracturing experiment at Rio Blanco, northwest of Rifle, Colorado, was designed to increase natural gas production from low-permeability sandstone.

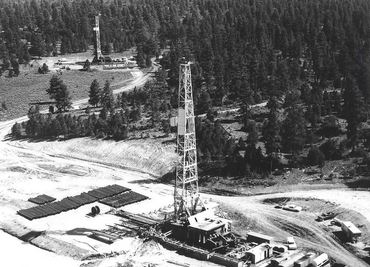

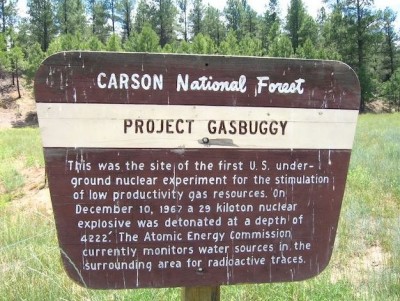

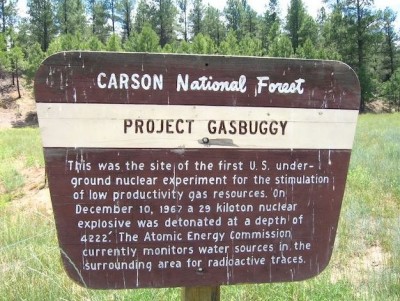

Gasbuggy: “Site of the first United States underground nuclear experiment for the stimulation of low-productivity gas reservoirs.” Photo Courtesy DOE.

The May 1973 Rio Blanco test consisted of the nearly simultaneous detonation of three 33-kiloton devices in a single well, according to the Office of Environmental Management. The explosions occurred at depths of 5,838, 6,230, and 6,689 feet below ground level. It would prove to be the last experiment of the Plowshare program.

Although a 50-kiloton nuclear explosion to fracture deep oil shale deposits — Project Bronco — was proposed, it never took place. Growing knowledge (and concern) about radioactivity ended these tests for the peaceful use of nuclear explosions. The Plowshare program was canceled in 1975.

After an examination of all the nuclear test projects, the U.S. Department of Energy September 2011 reported:

By 1974, approximately 82 million dollars had been invested in the nuclear gas stimulation technology program (i.e., nuclear tests Gasbuggy, Rulison, and Rio Blanco). It was estimated that even after 25 years of gas production of all the natural gas deemed recoverable, only 15 to 40 percent of the investment could be recovered. At the same time, alternative, non-nuclear technologies were being developed, such as hydrofracturing.

DOE concluded, Consequently, under the pressure of economic and environmental concerns, the Plowshare Program was discontinued at the end of FY 1975.

Project Gasbuggy: Nuclear Fracking

“There was no mushroom cloud, but on December 10, 1967, a nuclear bomb exploded less than 60 miles from Farmington,” explained historian Wade Nelson in an article written three decades later, “Nuclear explosion shook Farmington.”

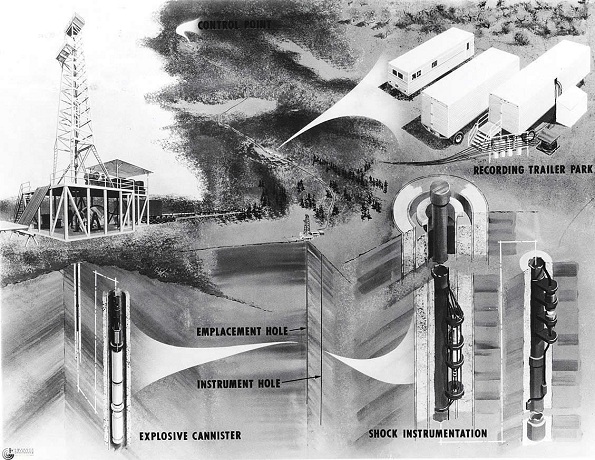

Government scientists believed a nuclear device would provide “a bigger bang for the buck than nitroglycerin” for fracturing dense shales and releasing natural gas. Illustration courtesy Los Alamos Lab.

The 4,042-foot-deep detonation created a molten glass-lined cavern about 160 feet in diameter and 333 feet tall. It collapsed within seconds. Subsequent measurements indicated fractures extended more than 200 feet in all directions — and significantly increased natural gas production.

A September 1967 Popular Mechanics article described how nuclear explosives could improve previous fracturing technologies, including gunpowder, dynamite, TNT — and fractures “made by forcing down liquids at high pressure.”

Hydraulic fracturing technologies pump a mixture of fluid and sand down a well at extremely high pressure to stimulate production of oil and natural gas wells.

The first commercial application of hydraulic fracturing took place in March 1949 near Duncan, Oklahoma, following experiments in a Kansas natural gas field. Increasing oil production by fracturing geologic formations had begun about a century earlier (see Shooters – A “Fracking” History).

A 1967 illustration in Popular Mechanics magazine showed how a nuclear explosive would improve earlier technologies by creating bigger fractures and a “huge cavity that will serve as a reservoir for the natural gas.”

Scientists predicted that nuclear explosives would create more and bigger fractures “and hollow out a huge cavity that will serve as a reservoir for the natural gas” released from the fractures.

“Geologists had discovered years before that setting off explosives at the bottom of a well would shatter the surrounding rock and could stimulate the flow of oil and gas,” Nelson explained. “It was believed a nuclear device would simply provide a bigger bang for the buck than nitroglycerin, up to 3,500 quarts of which would be used in a single shot.”

The first 1967 underground detonation test was part of a broader federal program begun in the late 1950s to explore the peaceful uses of nuclear explosions.

“Today, all that remains at the site is a plaque warning against excavation and perhaps a trace of tritium in your milk,” Nelson added in his 1999 article. He quoted James Holcomb, the site foreman for El Paso Natural Gas, who saw a pair of white vans that delivered pieces of the disassembled nuclear bomb.

“They put the pieces inside this lead box, this big lead box…I (had) shot a lot of wells with nitroglycerin and I thought, ‘That’s not going to do anything,” reported Holcomb. A series of three production tests, each lasting 30 days, was completed during the first half of 1969. Government records indicated the Gasbuggy well produced 295 million cubic feet of natural gas.

“Nuclear Energy: Good Start for Gasbuggy,” proclaimed the December 22, 1967, TIME magazine. The Department of Energy, which had hoped for much higher production, determined that Tritium radiation contaminated the gas. It flared — burned off — the gas during production tests that lasted until 1973. Tritium is a naturally occurring radioactive form of hydrogen.

A 2012 Nuclear Regulatory Commission report noted, “Tritium emits a weak form of radiation, a low-energy beta particle similar to an electron. The tritium radiation does not travel very far in air and cannot penetrate the skin.”

A plaque marks the site of Project Gasbuggy in the Carson National Forest, 90 miles northwest of Santa Fe, New Mexico.

According to Nelson, radioactive contamination from the flaring “was minuscule compared to the fallout produced by atmospheric weapons tests in the early 1960s.” From the well site, Holcomb called the test a success. “The well produced more gas in the year after the shot than it had in all of the seven years prior,” he said.

In 2008, the Energy Department’s Office of Legacy Management assumed responsibility for long-term surveillance and maintenance at the Gasbuggy site. A marker placed at the Gasbuggy site by the Department of Energy in November 1978 reads:

Site of the first United States underground nuclear experiment for the stimulation of low-productivity gas reservoirs. A 29 kiloton nuclear explosive was detonated at a depth of 4227 feet below this surface location on December 10, 1967. No excavation, drilling, and/or removal of materials to a true vertical depth of 1500 feet is permitted within a radius of 100 feet of this surface location. Nor any similar excavation, drilling, and/or removal of subsurface materials between the true vertical depth of 1500 feet to 4500 feet is permitted within a 600 foot radius of t 29 n. R 4 w. New Mexico principal meridian, Rio Arriba County, New Mexico without U.S. Government permission.

USSR’s Project NEVA

The Union of Soviet Socialist Republics (USSR) responded with its own more extensive program in 1965, according to a declassified 1981 Central Intelligence Agency report.

The CIA assessment, “The Soviet Program for Peaceful Uses of Nuclear Explosions,” reported that by the mid-1970s, the Soviets had detonated nine nuclear devices in seven Siberian fields to increase natural gas production as part of Project NEVA – Nuclear Explosions for the National Economy.

The USSR atomic tests delivered essentially the same conclusion as did America’s Project Gasbuggy – no commercially feasible petroleum production — and not popular with the public because of environmental concerns. The USSR abandoned Project NEVA experiments in 1989, more than a decade after the end of America’s Plowshare program.

Parker Drilling Rig No. 114

In 1969, Parker Drilling Company signed a contract with the U.S. Atomic Energy Commission to drill a series of holes up to 120 inches in diameter and 6,500 feet in depth in Alaska and Nevada for additional nuclear bomb tests. Parker Drilling’s Rig No. 114 was one of three special rigs built to drill the wells.

Parker Drilling Rig No. 114 was among those used to drill wells for nuclear detonations and later modified to drill conventional, very deep wells. Since 1991, the 17-story rig has welcomed visitors to Elk City, Oklahoma, next to the shuttered Anadarko Museum of Natural History. Photo by Bruce Wells.

Founded in Tulsa in 1934 by Gifford C. Parker, by the 1960s Parker Drilling had set numerous world records for deep and extended-reach drilling.

According to the Baker Library at the Harvard Business School, the company “created its own niche by developing new deep-drilling technology that has since become the industry standard.”

Following completion of the nuclear-test wells, Parker Drilling modified Rig No. 114 and its two sister rigs to drill conventional wells at record-breaking depths.

After retiring Rig No. 114 from oilfields, Parker Drilling in 1991 loaned it to Elk City, Oklahoma, as an energy education exhibit next to the Anadarko Museum of Natural History, which later closed. The 17-story rig has remained there to welcome Route 66 and I-40 travelers.

Learn about drilling miles deep in Anadarko Basin in Depth.

_______________________

Recommended Reading: Atoms for Peace and War 1953-1961 (2017); Project Plowshare: The Peaceful Use of Nuclear Explosives in Cold War America

(2017); Project Plowshare: The Peaceful Use of Nuclear Explosives in Cold War America (2012). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

(2012). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

_______________________

The American Oil & Gas Historical Society (AOGHS) preserves U.S. petroleum history. Please become an AOGHS annual supporter and help maintain this energy education website and expand historical research. For more information, contact bawells@aoghs.org. Copyright © 2024 Bruce A. Wells. All rights reserved.

Citation Information – Article Title: “Project Gasbuggy tests Nuclear “Fracking”.” Authors: B.A. Wells and K.L. Wells. Website Name: American Oil & Gas Historical Society. URL: https://aoghs.org/technology/project-gasbuggy. Last Updated: December 4, 2024. Original Published Date: December 10, 2013.

by Bruce Wells | Nov 20, 2024 | Petroleum Technology

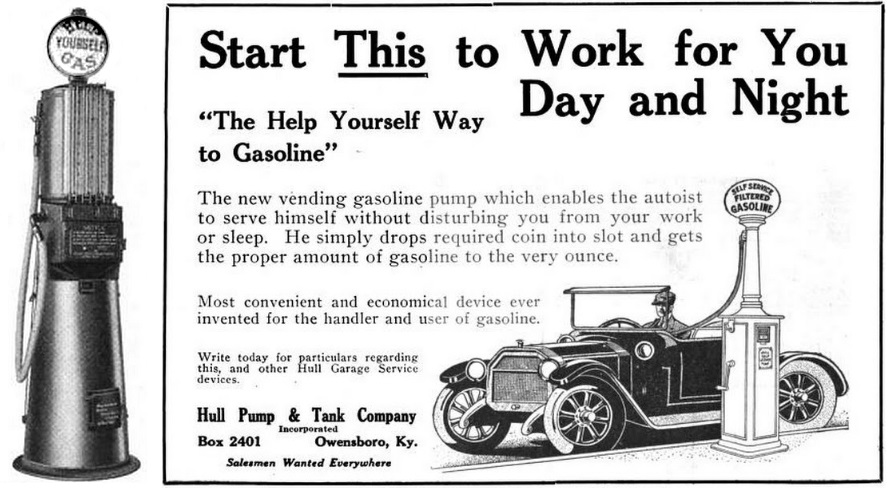

“Drop the coin in the slot…Mr. Robot delivers the correct amount of gasoline.”

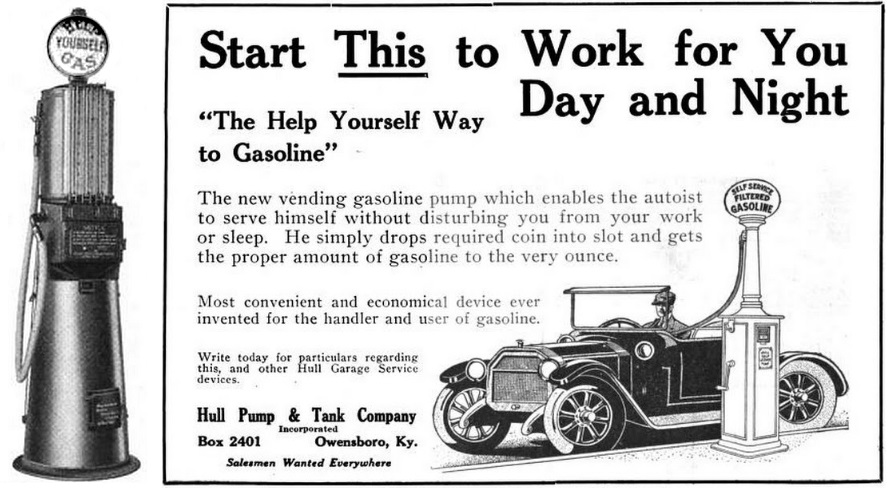

Almost as soon as gasoline service stations appeared, inventors began experimenting with ways to make user-friendly pumps for consumers. The revenue possibilities of 24-hour self-service gasoline pumps prompted a number of innovators to develop coin-operated systems in the early 20th Century.

Self-measuring pumps once used to dispense kerosene were adapted for gasoline (see Wayne’s Self-Measuring Pump), even as inventors sought ways to automate payment at the pump.

Scientific American and Popular Mechanics featured some of the early designs for coin-operated gasoline pumps, noting that manufacturers had taken their cue from “the fortunes that have resulted from the harvest of pennies dropped into chewing gum slot machines.”

Trade magazines like Garage Dealer and Motor Age featured advertisements for coin-operated gas pump technologies of the 1920s.

But a coin-operated pump had risks, noted editors at Scientific American: “It is evident that a vending machine liable to hold fifty or a hundred half-dollars would be a magnet for thieves.”

The Anthony Liquid Vending Machine Company designed its “Anthony Automatic Salesman,” which the company marketed to garage owners. promising a savings of $5 in overhead costs for every dollar invested in the automatic, coin-operated pumps.

In Minnesota, William H. Fruen received the first U.S. patent for a coin-operated liquid dispensing apparatus in 1884. The inventor from Minneapolis designed an innovative “Automatic Liquid-Drawing Device,” according to Canadian historian K.J. Zeoli.

Starky Coin-Operated Pumps

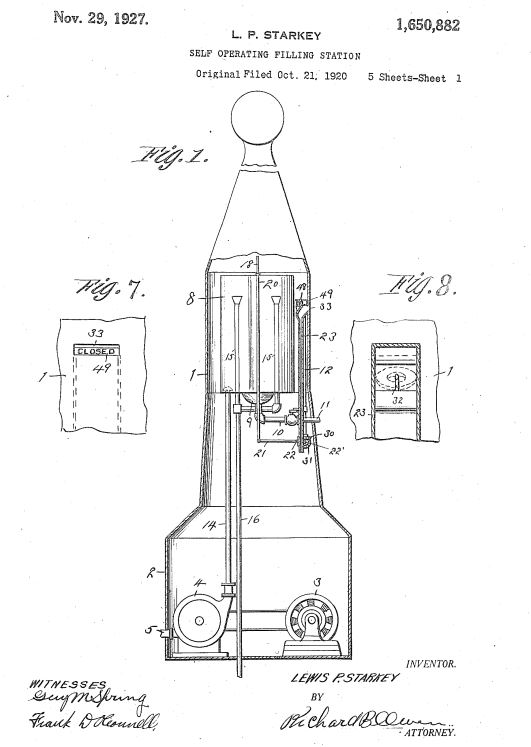

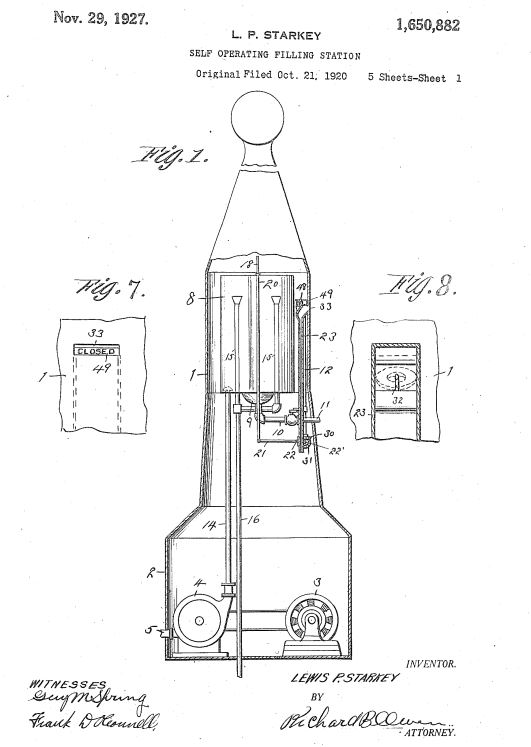

One of the better known coin-operated pump manufacturers originated with the Starkey Oil and Gas Company of Fort Collins, Colorado. Lewis P. Starkey, who first filed an application in October 1920, received his U.S. patent on November 29, 1927 (patent no. 1650882), which used electricity instead of a manual cranking system.

Patent drawing of “Self-Operating Filling Station,” the coin-operated gasoline pump invented by Lewis Starkey of Fort Collins, Colorado.

According to Zeoli, the L.P. Starkey Pump Company, which was later sold to Gas-O-Mat Inc. of Denver, produced two models of coin-operated pumps.

“Starkey and his wife ran a service station in Fort Collins. Starkey was constantly being awakened during the night by tourists who wanted gasoline. His wife actually came up with the idea of making a gas pump that would dispense gas without Starkey having to get out of bed and service the tourist. This gave Starkey the idea for the coin operated pump.”

“Unfortunately, Starkey allowed his patent to expire on one of the key components in his pumps,” Zeoli reported. The component, a “silent mercury switch” that prevented electrical circuits sparks, “went on to be used by thousands in the construction business.”

Although coin-operated pumps at gas service stations would prove impractical, there were notable attempts in the early 20th century, according to Zeoli. The October 18, 1913, issue of Popular Mechanics featured “The Gasoline Slot Machine,” reporting how an automatic pump did not require an attendant. Motorists could insert a half dollar coin into a slot and turn a crank.

The automatic pump was “touted as one of the first consumer friendly slot gas machines of the era,” Zeoli explains at the website Vintage Gas Pump & Oil History, adding, “The pump was so advanced, if a customer dropped a coin into an empty pump by mistake, the pump would return the coin after the first crank of the pump.”

Meanwhile, gasoline filling stations with uniformed attendants continued to expand nationwide following Gulf Oil’s example in Pittsburgh (see First Gas Pump and Service Station). Starkey Pump Company and other examples of the gas pump slot machines survive today in museums.

End of Gas-O-Mats

Gasoline dispensing automation seemed like a good idea simply lacking technology to make it work. Attempts continued as commercial names like Beacon, Gas-O-Mat, and others disappeared in a flurry of patents that could not overcome challenges of coin-operated pumps.

“You can sell gasoline 24-hours a day and 365-days a year, without effort on your part,” one company proclaimed, adding that paying was a simple process for consumers. “Drop the coin in the slot — a quarter, half-dollar, or a silver dollar, and Mr. Robot delivers the correct amount of gasoline.”

By 1915, an article in National Petroleum News reported a key drawback of unattended, coin-operated pumps: “One gasoline vending outfit tried out recently in a middle western city returned about $2 in real currency and $37 in lead slugs, buttons and counterfeit coins for its first 500 gallons of gasoline.”

Nonetheless, as a system for numbered highways was established, and U.S. 66 from Chicago to Los Angeles approved in 1926 (learn more in America On the Move), some coin-operated machines survived into the 1930s.

__________________________

The American Oil & Gas Historical Society (AOGHS) preserves U.S. petroleum history. Please become an AOGHS annual supporter and help maintain this energy education website and expand historical research. For more information, contact bawells@aoghs.org. Copyright © 2024 Bruce A. Wells. All rights reserved.

Citation Information – Article Title: “Coin Operated Gas Pumps.” Authors: B.A. Wells and K.L. Wells. Website Name: American Oil & Gas Historical Society. URL: https://aoghs.org/technology/coin-operated-gasoline-pumps. Last Updated: November 20, 2024. Original Published Date: July 11, 2018.

by Bruce Wells | Nov 5, 2024 | Petroleum Technology

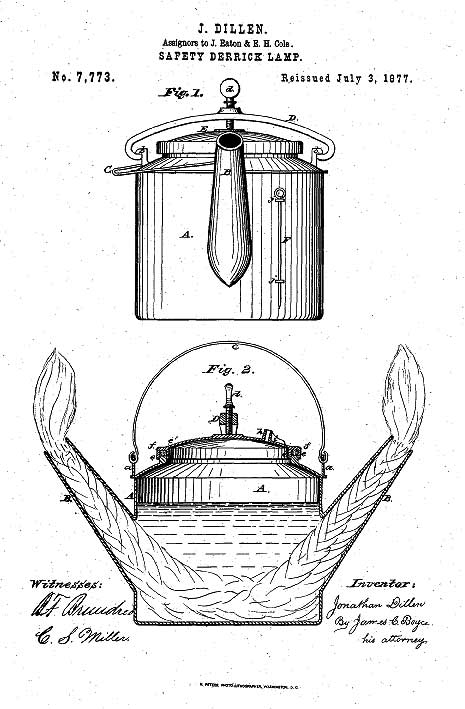

A two-wicked safety lamp for preventing “destructive conflagrations” on oil derricks.

Oil patch lore says “Yellow Dog” lanterns got their name because of two burning wicks that resembled a dog’s glowing eyes at night. Others say the lamps cast an eerie dog’s head shadow on the derrick floor.

Rare is the community oil museum that doesn’t have a Yellow Dog in its collection. Officially patented a decade after the Civil War, the two-wicked “Derrick Safety Lamp” would become an oilfield icon. But long before Yellow Dogs found their way to the oil patch, a similar design burned animal fat atop America’s lighthouses.

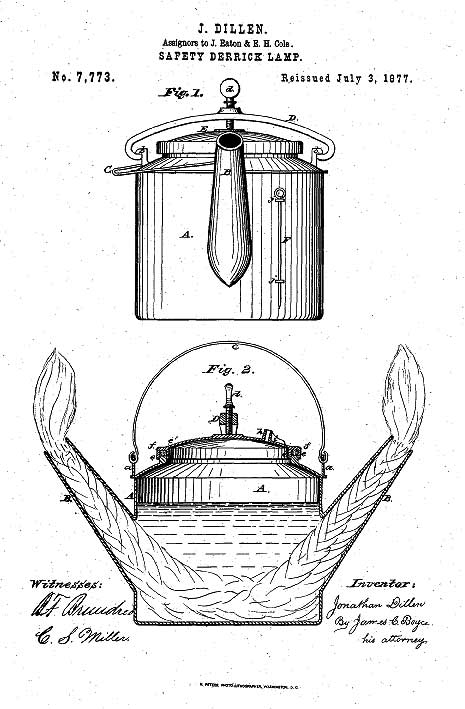

First patented in 1870, Jonathan Dillen’s lantern was “adapted for use in the oil regions…where the explosion of a lamp is attended with great danger by causing destructive conflagration and consequent loss of life and property.”

By the late 1700s, the cylindrical “Bucket Lamp” included two or four spouts protruding from its sides, according to Thomas Tag in Lighthouse Lamps Through Time. “Each spout carried a large diameter rope wick that extended down inside the body of the lamp into the oil.”

As late as 1874, four years after Yellow Dog lamp patent, the U.S. Lighthouse Board of the Department of Treasury continued to mandate the use of lard for fueling the beacons, later rejecting electricity and natural gas because of “the complexity and cost of the apparatus.”

By 1877, the Lighthouse Board changed its illumination mandate to kerosene, which would be supplanted by electric arc lamps and followed by incandescent bulbs.

Inventing the Yellow Dog

Despite its many oilfield service manufacturers, the Yellow Dog’s origins remain in the dark. Some historical sources claim the derrick lamp’s design originated with the whaling industry, but neither the Nantucket nor New Bedford whaling museums have found any such evidence.

Railroad museums often include collections of cast iron smudge pots, but nothing approaching the heavy, crude-oil burning lanterns once prevalent in oilfields from Pennsylvania to California.

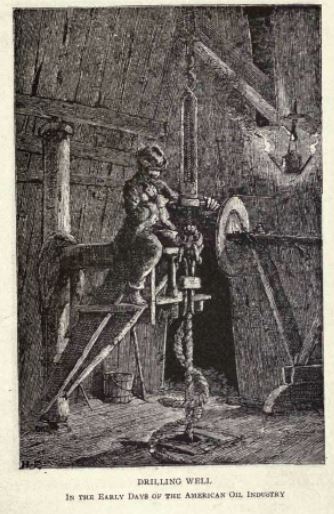

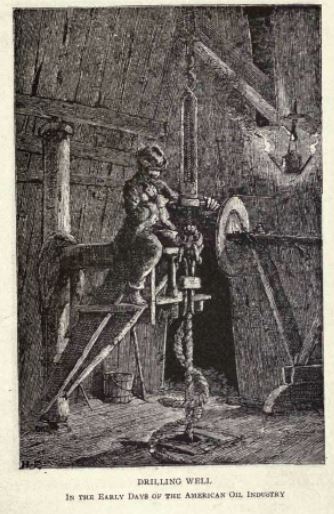

A 19th century illustration of a cable-tool driller with his nearby Yellow Dog lantern.

Inventor Jonathan Dillen of Petroleum Centre, Pennsylvania, was first to patent what became the iconic lantern of the early years of the petroleum industry. His U.S. patent was awarded on May 3, 1870. The two-wicked lamp joined other safety innovations as drilling technologies evolved.

The lamp was designed “for illuminating places out of doors, especially in and about derricks, and machinery in the oil regions, whereby explosions are more dangerous and destructive to life and property than in most other places.”

“My improved lamp is intended to burn crude petroleum as it comes from the wells fresh and gassy,” Dillen proclaimed. “It is to be used, mainly, around oil wells, and its construction is such as to make it very strong, so that it cannot be easily broken or exploded.”

Dillen’s Yellow Dog patent was improved upon and reissued in 1872 and again in 1877, when it was assigned to a growing oilfield equipment supplier.

Oil Well Supply Company

In 1861, John Eaton made a business trip to the booming oil region of western Pennsylvania. Within a few years, he had set up his own business with Edward Cole. With the addition of Edward Burnham, the company grew to become a preeminent supplier of oilfield equipment.

In early Pennsylvania oilfields, a John Eaton biography by his great-grandson noted Eaton was considered “father of the well supply trade.”

By 1877, Eaton, Cole & Burnham oilfield supply had outlets in the Pennsylvania oil regions, including Pittsburgh and Bradford. The company changed its name Oil Well Supply Company the next year, according to a biography by his great-grandson, Louis B. Fleming.

“The first goods manufactured by the Oil Well Supply Company were made on a foot lathe,” John Eaton would recall. The oilfield equipment supply company was operating 75 manufacturing plants by the turn of the 20 century.

The biography, John Eaton, by journalist Fleming, cited the classic 1898 book Sketches in Crude Oil, which noted that Oil Well Supply company’s founder and president “may fairly claim to be the father of the well supply trade.”

A Pennsylvania Historical and Museum Commission roadside marker erected in Oil City in 1992 notes: “Oil Well Supply Company — Founded nearby in 1878, it was a leading manufacturer of oil well machinery and supplies, serving the oil industry across the globe. By the early 1900s, employment peaked at 2,000. In 1930 it became a subsidiary of United States Steel.”

Incorporated in Pennsylvania – the Keystone State – Forest Oil’s logo features the iconic two-wicked lamp invented in 1870.

In Oil City at its 45-acre Imperial Works on the Allegheny River, Oil Well Supply manufactured oilfield engines and “cast and malleable iron goods” that included the two-wicked derrick safety lamp. The 1884 Oil Well Supply catalog listed Yellow Dog lamps at a price of $1.50 each.

Today, along with their shadowy origins, the Yellow Dog lanterns are relegated to museums, antique shops and collectors. They sometimes can be found on display next to another unusual two-wicked lamp (see Camphene to Kerosene Lamps).

Forest Oil Company Logo

After experimenting with injecting water into some wells to increase production from others, Forest Dorn partnered with his father Clayton in 1916 to establish Forest Oil, an oilfield service company in Pennsylvania’s giant Bradford oilfield.

The company in February 1824 adopted the two-wicked oilfield derrick lamp as part of its logo, which included a keystone shape inside the lantern to symbolize the state of Pennsylvania — where the first commercial U.S. oil well was drilled in Titusville in 1859.

Forest Oil Company developed an extremely efficient technique for “secondary recovery” of trapped petroleum reservoirs. The waterflooding proved revolutionary for improving oilfield production nationwide. The technological leap began at America’s first giant oilfield, discovered in 1871 in Bradford, about 70 miles east of Titusville .

An oil museum near Bradford, Pennsylvania, educates visitors using a replica of an 1880s standard cable-tool derrick. Photo by Bruce Wells.

By 1916, oil production in the Bradford field had declined to just under 40 barrels a day. The reserve was considered by many to be dry — until Forest Dorn had applied his water-flooding technique to initiate secondary recovery of oil. Forest Oil became a recognized as a leader in secondary oil recovery systems.

Water-flooding boosted oilfield production as demand for gasoline for automobiles was growing (learn more in Cantankerous Combustion – First U.S. Auto Show).

As the science of petroleum geology (and petroleum engineering) advanced, secondary recovery technologies evolved nationwide. Enhanced recovery technologies have been applied throughout the petroleum industry — aiding in the extension of oil wells’ lives by as much as 10 years.

In Texas, the already considerable production from the largest oilfield in the lower-48 states, the East Texas oilfield, has continued since its first well, the Daisy Bradford No. 3, drilled in 1930.

Oil Museums

The history of America’s “first billion dollar oilfield” is on exhibit at the Penn-Brad Historical Oil Park and Museum near Bradford, Pennsylvania — where a modern natural gas shale boom has renewed an historic oil patch economy.

Located in Custer City, three miles south of Bradford (home of Zippo lighters), the museum (maintained by many dedicated volunteers) “preserves the philosophy, the spirit, and the accomplishments of an oil country community.”

One attraction of the Penn-Brad museum is its 72-foot standard cable-tool derrick and engine house, replicas of 1880s technology that helped Bradford once produce 74 percent of all U.S. oil. It’s another noteworthy stop among other excellent Pennsylvania oil museums a few hours west of Bradford at the Drake Well Museum in Titusville.

_______________________

Recommended Reading: Early Days of Oil: A Pictorial History of the Beginnings of the Industry in Pennsylvania (2000); Images of America: Around Bradford

(2000); Images of America: Around Bradford (1997); The Prize: The Epic Quest for Oil, Money & Power (1991). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

(1997); The Prize: The Epic Quest for Oil, Money & Power (1991). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

_______________________

The American Oil & Gas Historical Society (AOGHS) preserves U.S. petroleum history. Please become an AOGHS annual supporter and help maintain this energy education website and expand historical research. For more information, contact bawells@aoghs.org. © 2024 Bruce A. Wells. All rights reserved.

Citation Information – Article Title: “Yellow Dog – Oilfield Lantern.” Authors: B.A. Wells and K.L. Wells. Website Name: American Oil & Gas Historical Society. URL: https://aoghs.org/technology/yellow-dog-oil-field-lantern. Last Updated: November 5, 2024. Original Published Date: September 1, 2008.

(2017); Project Plowshare: The Peaceful Use of Nuclear Explosives in Cold War America

(2012). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.