by Bruce Wells | Apr 4, 2025 | Petroleum Transportation

Densmore brothers advanced oil industry infrastructure — and helped create “QWERTY” typewriter keyboard.

As Northwestern Pennsylvania oil production skyrocketed following the Civil War, railroad oil tank cars fabricated by two brothers improved shipment volumes from oilfields to kerosene refineries. The tank car designed by James and Amos Densmore would not last, but more success followed when Amos invented a new keyboard arrangement for typewriters.

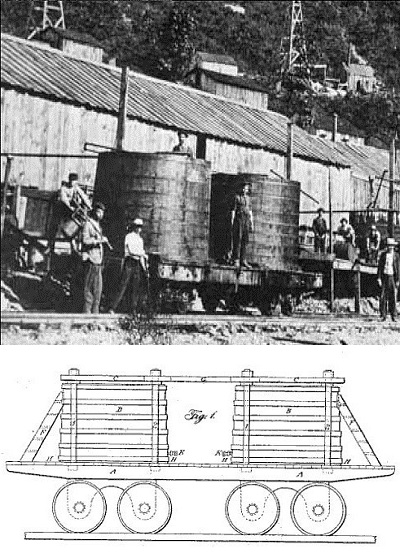

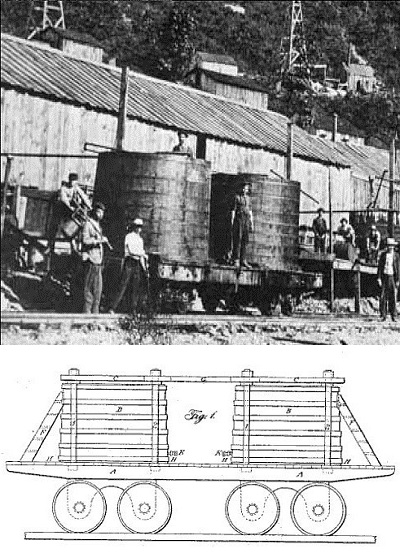

Flatbed railroad cars with two wooden oil tank cars became the latest advancement in oilfield infrastructure after the Densmore brothers patented their design on April 10, 1866.

The inventors from Meadville, Pennsylvania, had developed an “Improved Car for Transporting Petroleum” one year earlier in America’s booming oil regions. The first U.S. oil well had been drilled just seven years earlier along Oil Creek in Titusville.

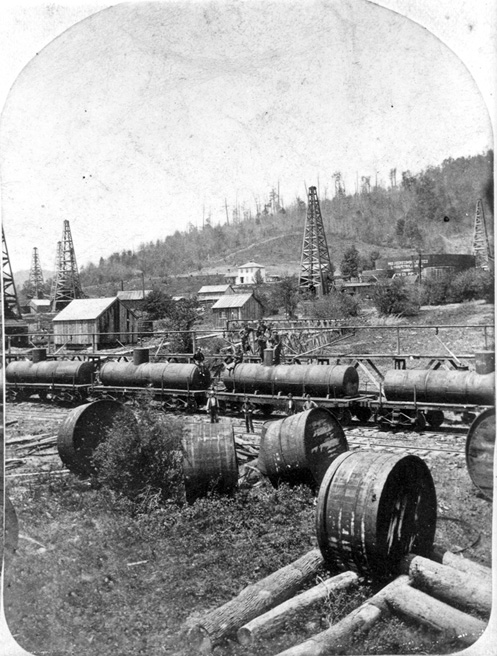

The first practical petroleum railway tank car was invented in 1865 by James and Amos Densmore at the Miller Farm along Oil Creek, Titusville, Pennsylvania. Photo courtesy Drake Well Museum.

Using an Atlantic & Great Western Railroad flatcar, the brothers secured two tanks to ship oil in bulk. The patent (no. 53,794) described and illustrated the railroad car’s design.

The nature of our invention consists in combining two large, light tanks of iron or wood or other material with the platform of a common railway flat freight-car, making them practically part of the car, so as they carry the desired substance in bulk instead of in barrels, casks, or other vessels or packages, as is now universally done on railway cars.

Development of railroad tank cars came when traditional designs, including the flatcar, hopper, and boxcar, proved inadequate for large amounts of oil — often shipped in 42-gallon barrels.

New designs were born out of necessity, as the fledgling oil industry demanded a better car for the movement of its product, according to American-Rails.com.

“Before the car was developed, railroads used a combination of boxcars, flatcars, and gondolas to haul everything from lumber and coal to crude oil, molasses, and water (by use of barrels),” noted Adam Burns in 2022. “One of the most prolific car types you will find moving within a freight train today is the tank car.”

Prone to leaks and top heavy, Densmore tank cars provided a vital service, if only for a few years before single, horizontal tanks replaced them.

According to transportation historian John White Jr., the Densmore brothers’ oil tank design essentially consisted of a flat car with wooden vats attached. “The Central Pacific is known to have used such specialized cars to transport water, he noted in his 1995 book, The American Railroad Freight Car.

“However, prior to the discovery of oil by Colonel Edward (sic) Drake near Titusville, Pennsylvania, on August 27, 1859, the tank car was virtually non-existent,” added White, a former curator of Transportation at the Smithsonian Institution.

Dual Tank Design

The brothers further described the use of special bolts at the top and bottom of their tanks to act as braces and “to prevent any shock or jar to the tank from the swaying of the car while in motion.”

A Pennsylvania Historical Commission marker on U.S. 8 south of Titusville commemorates the Densmore brothers’ significant contribution to petroleum transportation technology. Dedicated in 2004, the marker notes:

The first functional railway oil tank car was invented and constructed in 1865 by James and Amos Densmore at nearby Miller Farm along Oil Creek. It consisted of two wooden tanks placed on a flat railway car; each tank held 40-45 barrels of oil. A successful test shipment was sent in September 1865 to New York City. By 1866, hundreds of tank cars were in use. The Densmore Tank Car revolutionized the bulk transportation of crude oil to market.

The benefit of such railroad cars to the early petroleum industry’s infrastructure was immense, especially as more Americans eagerly sought oil-refined kerosene for lamps.

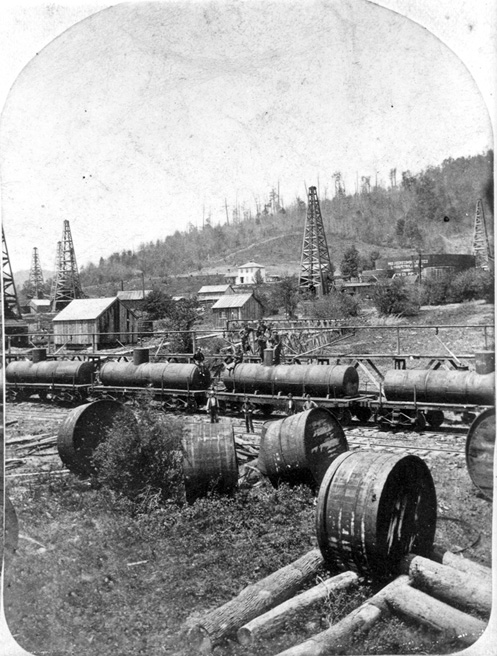

Despite design limitations that would prove difficult to overcome, independent producers took advantage of the opportunity to transport large amounts of petroleum. Other transportation methods required teamsters hauling barrels to barges on Oil Creek and the Allegheny River to get to kerosene refineries in Pittsburgh.

Riveted cylindrical iron tank cars replaced the Densmore brothers’ dual wooden tanks — seen here discarded. Photo courtesy Drake Well Museum.

As larger refineries were constructed, it was found that it cost $170 less to ship 80 barrels of oil from Titusville to New York in a tank car instead of individual barrels. But the Densmore cars had flaws, notes the Pennsylvania Historical Commission.

They were unstable, top heavy, prone to leaks, and limited in capacity by the eight-foot width of the flatcar. Within a year, oil haulers shifted from the Densmore vertical vats to larger, horizontal riveted iron cylindrical tanks, which also demonstrated greater structural integrity during derailments or collisions.

The same basic cylindrical design for transporting petroleum can be seen as modern railroads load products from corn syrup to chemicals — all in a versatile tank car that got its start in the Pennsylvania oil industry.

The largest tank car ever placed into regular service was Union Tank Car Company’s UTLX 83699, rated at 50,000 gallons in 1963 and used for more than 20 years. A 1965 experimental car built by General American Transportation, the 60,000-gallon “Whale Belly,” GATX 96500, is now on display at the National Museum of Transportation in Saint Louis.

1863 Tank Car Patents

Although not manufactured, other inventors came up with new ways for transporting oil from booming oilfields. John Scott of Lawrenceville, Pennsylvania, on January 20, 1863, patented (No. 37,461) a rectangular design for his “car for carrying petroleum, etc.”

John Clark of Canandaigua, New York, on November 3, 1863, was awarded a patent (No. 40,458) for another “improvement in cars for carrying petroleum.” His design put a long and flat sheet-metal tank under an ordinary freight car.

Finally, a “Petroleum Car” design with a cylindrical shape similar to modern railroad tank cars was patented (No. 38,765) on June 2, 1863, by Samuel J. Seely of Bookland, New York. The Seely patent might be the first design for a petroleum car shaped like those in use today.

Oil Tanks to Typewriters

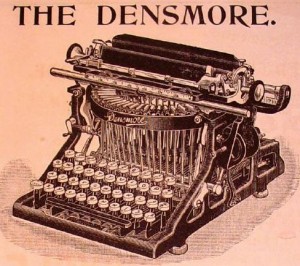

Although the Densmore brothers left the oil region by 1867 — their inventiveness was far from over. In 1875, Amos Densmore assisted Christopher Sholes in rearranging the “type writing machine” keyboard so that commonly used letters no longer collided and got stuck. The “QWERTY” arrangement vastly improved Shole’s original 1868 invention.

Amos Densmore helped invent one of the first practical typewriters.

Following his brother’s work with Sholes, inventor of the first practical typewriter, James Densmore’s oilfield financial success helped the brothers establish the Densmore Typewriter Company, which produced its first model in 1891. Few historians have made the oil patch to typewriter keyboard connection — including Densmore biographers.

The Pennsylvania Historical Commission reported that biographies of the Densmore brothers — and their personal papers at the Milwaukee Public Museum — all refer to their innovative typewriters, “but make no mention of their pioneering accomplishment in railroad tank car design.”

_______________________

Recommended Reading: The American Railroad Freight Car (1995); Early Days of Oil: A Pictorial History of the Beginnings of the Industry in Pennsylvania (2000); Story of the Typewriter, 1873-1923 (2019); Myth, Legend, Reality: Edwin Laurentine Drake and the Early Oil Industry

(2000); Story of the Typewriter, 1873-1923 (2019); Myth, Legend, Reality: Edwin Laurentine Drake and the Early Oil Industry (2009). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

(2009). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

_______________________

The American Oil & Gas Historical Society (AOGHS) preserves U.S. petroleum history. Please become an AOGHS annual supporter and help maintain this energy education website and expand historical research. For more information, contact bawells@aoghs.org. © 2025 Bruce A. Wells. All rights reserved.

Citation Information – Article Title: “Densmore Oil Tank Cars.” Authors: B.A. Wells and K.L. Wells. Website Name: American Oil & Gas Historical Society. URL: https://aoghs.org/transportation/densmore-oil-tank-car. Last Updated: July 14, 2025. Original Published Date: April 7, 2013.

by Bruce Wells | Mar 18, 2025 | Petroleum Transportation

“No one anticipated any unusual problems as the Exxon Valdez left the Alyeska Pipeline Terminal at 9:12 p.m., Alaska Standard Time,” an account by the Alaska Oil Spill Commission would later report about the March 24, 1989, offshore disaster.

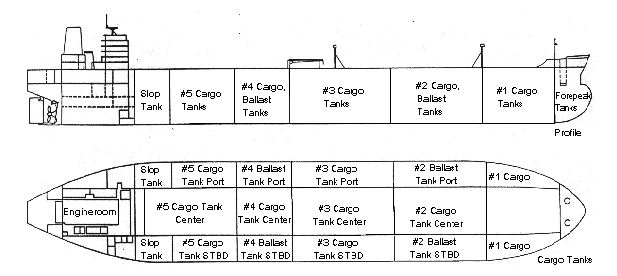

After nearly a dozen years of routine daily passages through Prince William Sound, Alaska, an oil tanker ran aground, rupturing the hull. Supertanker Exxon Valdez hit Bligh Reef and spilled more than 260,000 barrels of oil, affecting hundreds of miles of coastline. Some consider the spill amount used by Alaska’s Exxon Valdez Oil Spill Trustee Council as too conservative.

Field studies continue to examine the effects of the Exxon supertanker’s disastrous grounding on Bligh Reef in Alaska’s Prince William Sound in 1989. Photo courtesy Erik Hill, Anchorage Daily News.

A General Complacency

When the 987-foot tanker hit the reef shortly after midnight, “the system designed to carry two million barrels of North Slope oil to West Coast and Gulf Coast markets daily had worked perhaps too well,” according to the Alaska Oil Spill Commission’s initial report.

“At least partly because of the success of the Valdez tanker trade, a general complacency had come to permeate the operation and oversight of the entire system,” the commission noted. Complacency about giant oil tankers ended on March 24, 1989, when the Exxon Valdez ran aground on Bligh Reef.

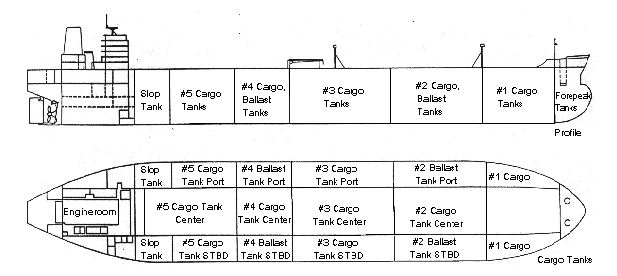

“The vessel came to rest facing roughly southwest, perched across its middle on a pinnacle of Bligh Reef,” added the commission’s report. “Eight of 11 cargo tanks were punctured. Computations aboard the Exxon Valdez showed that 5.8 million gallons had gushed out of the tanker in the first three and a quarter hours.”

“Eight of 11 cargo tanks were punctured. Computations aboard the Exxon Valdez showed that 5.8 million gallons had gushed out of the tanker in the first three and a quarter hours.”

Tankers carrying North Slope crude oil had safely transited Prince William Sound more than 8,700 times during the previous 12 years. Improved shipbuilding technologies resulted in supersized vessels.

“Whereas tankers in the 1950s carried a crew of 40 to 42 to manage about 6.3 million gallons of oil…the Exxon Valdez carried a crew of 19 to transport 53 million gallons of oil,” the report explained.

Alaskan weather conditions — 33 degrees with a light rain — and the remote location added to the 1989 disaster, the report continues. With the captain not present, the third mate made a navigation error, according to another 1990 investigation by the National Transportation and Safety Board, Practices that relate to the Exxon Valdez.

“The third mate failed to properly maneuver the vessel, possibly due to fatigue or excessive workload,” the Safety Board concluded.

Containing Oil Spills

At the time, spill response capabilities to deal with the spreading oil will be found to be unexpectedly slow and woefully inadequate, according to the Oil Spill Commission.

“The worldwide capabilities of Exxon Corporation would mobilize huge quantities of equipment and personnel to respond to the spill — but not in the crucial first few hours and days when containment and cleanup efforts are at a premium,” the commission’s report explained.

At 987 feet long and 166 feet wide, the Exxon Valdez — delivered to Exxon in December 1986 — was the largest ship ever built on the West Coast.

The commission added that the U.S. Coast Guard, “would demonstrate its prowess at ship salvage, protecting crews and lightering operations, but prove utterly incapable of oil spill containment and response.”

Spill Cleanup Lessons

Exxon began a cleanup effort that included thousands of Exxon and contractor personnel, according to ExxonMobil. More than 11,000 Alaska residents and volunteers rushed to the coastline to assist.

“Because Prince William Sound contained many rocky coves where the oil collected, the decision was made to displace it with high-pressure hot water,” noted a 2001 study for the American Academy of Underwater Sciences.

“However, this also displaced and destroyed the microbial populations on the shoreline; many of these organisms (e.g. plankton) are the basis of the coastal marine food chain, and others (e.g. certain bacteria and fungi) are capable of facilitating the biodegradation of oil,” explained scientific diving expert Stephen Jewett, professor emeritus of environmental studies at the University of Alaska, Fairbanks.

“At the time, both scientific advice and public pressure was to clean everything, but since then, a much greater understanding of natural and facilitated remediation processes has developed, due somewhat in part to the opportunity presented for study by the Exxon Valdez spill,” Jewett added.

His academic paper, “Scuba techniques used to assess the effects of the Exxon Valdez oil spill,” brought insights into mitigating the impact of the Alaskan oil spill — which had expedited passage of the Oil Pollution Act of 1990.

National Oceanic and Atmospheric Administration photo from 2014 study, “Twenty-Five Years After the Exxon Valdez Oil Spill: NOAA’s Scientific Support, Monitoring, and Research.”

According to ExxonMobil, the company spent $4.3 billion as a result of the accident, “including compensatory payments, cleanup payments, settlements and fines. The company voluntarily compensated more than 11,000 Alaskans and businesses within a year of the spill.”

A separate study by the Alaska Oil Spill Commission resulted in the February 1990 report, “Details about the Accident.” Scientists monitoring effects of the grounding have reported the ecosystem of Prince William Sound continues to recover, but it is healthy.

The National Oceanic and Atmospheric Administration (NOAA) in 2014 published the 78-page “Twenty-Five Years After the Exxon Valdez Oil Spill: NOAA’s Scientific Support, Monitoring, and Research” further examining the response.

In California two decades before the Exxon Valdez, the 1969 Santa Barbara oil spill from a Union Oil platform six miles off the coast led to the modern environmental movement — and establishment of the Environmental Protection Agency (EPA) a year later. Learn more in Oil Seeps and Santa Barbara Spill.

_______________________

Recommended Reading: The Exxon Valdez Oil Spill, Perspectives on Modern World History (2011); Slick Policy: Environmental and Science Policy in the Aftermath of the Santa Barbara Oil Spill

(2011); Slick Policy: Environmental and Science Policy in the Aftermath of the Santa Barbara Oil Spill (2018); Amazing Pipeline Stories: How Building the Trans-Alaska Pipeline Transformed Life in America’s Last Frontier

(2018); Amazing Pipeline Stories: How Building the Trans-Alaska Pipeline Transformed Life in America’s Last Frontier (1997). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

(1997). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

_______________________

The American Oil & Gas Historical Society (AOGHS) preserves U.S. petroleum history. Please become an AOGHS annual supporter and help maintain this energy education website and expand historical research. For more information, contact bawells@aoghs.org. © 2025 Bruce A. Wells. All rights reserved.

Citation Information – Article Title: “Exxon Valdez Oil Spill.” Authors: B.A. Wells and K.L. Wells. Website Name: American Oil & Gas Historical Society. URL: https://aoghs.org/transportation/exxon-valdez-oil-spill. Last Updated: March 18, 2025. Original Published Date: March 24, 2009.

by Bruce Wells | Jan 28, 2025 | Petroleum Transportation

Library of Congress photo tells many early automobile tales.

Picturing oil history: Details of an image in the Library of Congress digital collection offer insights into the early U.S. petroleum industry.

A single 1921 black-and-white photograph of a Washington, D.C., suburban gas station features petroleum products and transportation infrastructure just 20 years after the first U.S. auto show. Printed from an eight-inch by six-inch glass negative, the image features Takoma Park, Maryland, and its railroad station on the northeastern border of the District of Columbia.

(more…)

by Bruce Wells | Dec 23, 2024 | Petroleum Transportation

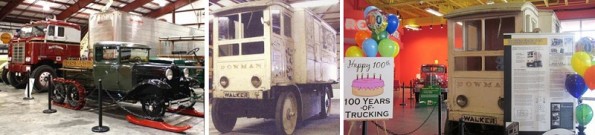

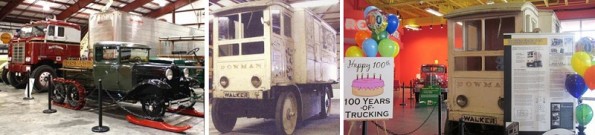

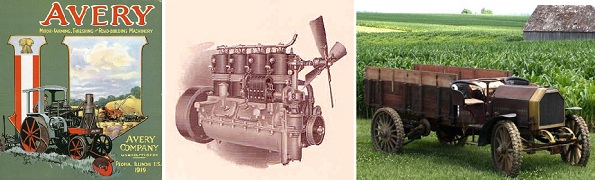

Beginning soon after its 1979 opening day, the Iowa 80 Trucking Museum has hosted an annual Jamboree attended by thousands. The museum in Walcott has more than 100 antique trucks on display, including an 1890 Standard Oil triple wagon; a 1903 Eldridge; a 1910 Avery tractor/gasoline farm wagon; and a 1911 Walker Electric Model 43.

The trucking collection off Interstate 80 at the “World’s Largest Truck Stop” began thanks to truck stop founder Bill Moon, who had a passion for trucks and truck history. Every summer, the museum at exit 284 on I -80 outside Walcott, Iowa, hosts a variety of events for truckers and other travelers, teachers, students — and transportation history buffs.

In 2024, the Iowa museum celebrated U.S. trucking history by showcasing its 1924 White Model 40 Wrecker, now on permanent display (and featured in the 1991 film Fried Green Tomatoes). The Model 40’s four-cylinder, 371-cubic-inch engine was produced at the White factory in Cleveland, Ohio, factory.

“If you are the least bit into cars you will find the museum interesting and well worth the stop,” notes a visitor from Legendary Collector Cars. “From what we could tell, it looks like this I-80 Exit at Walcott, Iowa, is about to become the over-the-road truckers Disneyland in a few years.”

“Bill had a passion for collecting antique trucks and other trucking memorabilia,” notes the Iowa 80 Trucking Museum website. “We are pleased to be able to share this collection with the general public. Every truck has a story to tell and can provide a unique glimpse back in time. Many rare and one-of-a-kind trucks are on display.”

The museum, which offers short films about trucking history, attracts all kinds of visitors, from those interested in antique trucks to those wanting to learn the history of modern, big rigs. Exhibit spaces, greatly expanded in 2012, today include free smartphone apps with audio narratives.

Since its inception in 1979, the Truckers Jamboree has been celebrating America’s Truckers. This event is a great place to celebrate and learn about trucking history — and those big rigs.

The descriptions provide additional details about each truck not found on the limited space of exhibit signs. Visitors can scan a “QR” code at the welcome desk to download the app. Upcoming museum visitors can download it from the website. The innovation — increasingly found at museums — allows both virtual and actual visitors to scan and download exhibit information.

Celebrating Trucking History

“The Iowa 80 Trucking Museum’s mission is to celebrate trucking and to preserve and share its history,” noted Marketing Director Heather DeBaillie in 2012. The smartphone apps, give visitors even more information about the exhibits, “and also give those who are unable to visit the museum the opportunity to learn more about trucking history,” she said.

A century of trucking technology is on exhibit at the Iowa 80 Trucking Museum, which on July 15, 2011, celebrated the birthday of its rare 1911 Walker electric truck, which once delivered dairy products.

The annual Jamborees in July host nearly 30,000 drivers and their families from 23 different states and Canada, according to the marketing director. During two days guests enjoyed 175 exhibits — and a Super Truck Beauty Contest with 59 contestants.

In 2011, the trucking museum hosted a birthday party for its Walker electric truck — with the party coinciding with the 32nd annual Walcott Truckers Jamboree at its next-door neighbor, the Iowa 80 Truck Stop, DeBaillie noted.

The antique truck display included more than 200 vehicles. Thousands also enjoyed an Iowa pork chop cookout; a Trucker Olympics; carnival games; a concert and fireworks display.

A 1929 International Harvester. Photo courtesy Legendary Collector Cars, which notes: “If you are the least bit into cars you will find the museum interesting and well worth the stop.”

Trucking Museum 1901 Electric Truck

The Walker truck’s 2011 centennial birthday party at the Iowa 80 Trucking Museum celebrated an electric manufactured by the Walker Vehicle Company of Chicago.

The company produced electric vehicles until late 1941. Walker trucks were used mainly as delivery trucks in major cities — delivering ice cream and other dairy products, baked goods and dry goods.

Although the 1919 International Harvester’s four-cylinder gasoline engine provided a top speed of just 17 mph, it was the first truck to climb Pike’s Peak.

The Iowa 80 Trucking Museum’s 1911 Walker electric truck was owned by Bowman Dairy and used to deliver milk to hospitals, restaurants and hotels, according to curator Dave Meier. It is one of only a handful of Walker Electric trucks known to still exist.

“Many people think that electric vehicles are a recent invention, when in fact they were in production over 100 years ago,” explained Meir.

Electric vehicles were popular in the late 19th century and early 20th century – until advances in internal combustion engine technology and mass production of cheaper gasoline vehicles led to a decline in their use (also see Cantankerous Combustion — 1st U.S. Auto Show).

Among the exhibits at the trucking museum is one of the few surviving examples of an Avery gasoline-powered tractor. Avery Company of Peoria, Illinois, began producing coal (and straw)-burning steam tractors in 1891 — and became the world’s largest tractor supplier. It was also one of the first companies to manufacture gasoline tractors.

Manufactured in Peoria, Illinois, Avery tractors brought new efficiency to rural America — and the world. The Iowa 80 Trucking Museum’s 1910 Avery “Tractor-Gasoline Farm Wagon” (at right) was promoted with the slogan, “Makes Power Farming Possible on the Average Sized Farm.”

Created by his family, the Iowa 80 Trucking Museum was a dream of Bill Moon, who founded the Iowa 80 truck stop. Standard Oil originally built the stop in 1964 – when Interstate 80 was still under construction. In September 1965, Moon took over management and purchased it from Amoco in 1984. He managed its growth until his death in 1992.

Plan a visit to the Iowa 80 Trucking Museum.

_______________________

The American Oil & Gas Historical Society (AOGHS) preserves U.S. petroleum history. Please become an AOGHS supporter and help maintain this energy education website and expand historical research. For more information, contact bawells@aoghs.org. Copyright © 2024 Bruce A. Wells. All rights reserved.

Citation Information – Article Title: “Iowa 80 Trucking Museum.” Authors: B.A. Wells and K.L. Wells. Website Name: American Oil & Gas Historical Society. URL: https://aoghs.org/oil-almanac/oil-riches-of-merriman-baptist-church. Last Updated: December 28, 2024. Original Published Date: April 18, 2012.

by Bruce Wells | Jun 23, 2024 | Petroleum Transportation

19th-century coopers made barrels of many capacities: hogsheads, puncheons, tierces, butts and tuns.

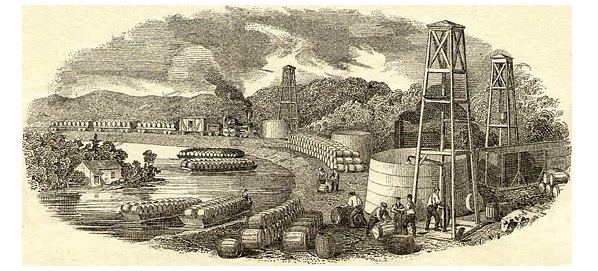

Soon after America’s first commercial oil well of 1859, a small group met in northwestern Pennsylvania and decided a 42-gallon wooden barrel was best for transporting their oil.

When filled with oil instead of fish or other commodities, a 42-gallon “tierce” weighed 300 pounds. The 42-gallon oil barrel was officially adopted in 1866. Today, a barrel’s refined products include about 20 gallons of gasoline, 12 gallons of diesel and four gallons of jet fuel (and rocket fuel) and other products, including asphalt.

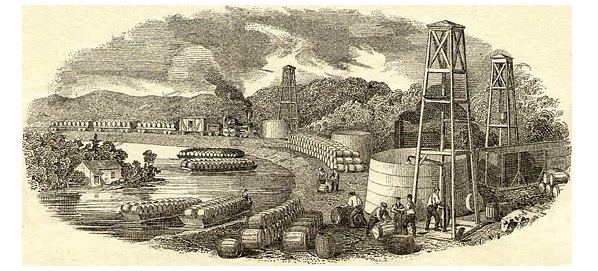

By the 1860s, barges floated barrels of oil down the Allegheny River to Pittsburgh to be refined into a highly demanded product – kerosene for lamps. Image from an early oil company stock certificate.

In August 1866 a handful of America’s earliest independent oil producers met in Titusville, Pennsylvania, and agreed that henceforth, 42 gallons would constitute a barrel of oil. Pennsylvania led the world in oil production as demand soared for kerosene lamp fuel. (more…)

by Bruce Wells | May 14, 2024 | Petroleum Transportation

From kerosene to gasoline, an 1892 Wayne Oil Tank & Pump Company dispenser preserves petroleum history.

Wayne Lease of White Salmon, Washington, owns a rare 1892 self-measuring pump originally designed to dispense kerosene. His pump is one of only 50 manufactured by the Wayne Oil Tank & Pump Company during its first year of business in Ft. Wayne, Indiana.

Lease has researched his petroleum technology artifact, learning it was manufactured for selling kerosene, the popular 19th century lamp fuel sold at mercantile stores. His Wayne Company hand-cranked, measured dispensing pump apparently was later modified to supply gasoline.

Original 1892 Wayne Oil Tank Company pump, one of just 50 manufactured to dispense kerosene during the company’s first year of business in Ft. Wayne, Indiana.

“My research indicates the Wayne pump was never manufactured to be used for gasoline, but rather kerosene only,” Lease noted in a 2020 email to the American Oil & Gas Historical Society.

He explained that many researchers of gasoline service station pumps have overlooked Wayne and other manufacturers’ altered pumps, “best defined as an ‘after strike,’ which allowed the use in the transfer of the more volatile gasoline.”

Self-measuring pump venders made good use of a dispenser that had become less needed because of electric lighting, Lease added.

The original Wayne Oil Tank & Pump Company design was limited to the specific use of kerosene as a lamp fuel, Lease explained. Kerosene was sold in general stores of rural America, where merchandise often could be found at stage coach stops spaced 15 miles to 25 miles apart.

Kerosene lamp fuel would be joined by a new transportation fuel in the early 1900s, gasoline for autos. “Small cities now become the hub of commerce on a larger scale with the introduction of the combustion engine,” he added. Kerosene would succumb to the Rural Electrification Act (1936) as gasoline became the U.S. consumer’s primary need.

“The Wayne pump, one of fifty made in1892, was then certified for the use of the transfer of Gasoline, and the vender made good use of what had become obsolete,” the amateur pump historian concluded in his 2020 email. He continues to research more information about the pump.

Detailed Wayne pump measurement scale 70 designed for dispensing kerosene and later, gasoline.

“It is in immaculate condition as you can see by the photographs, Lease noted. He is seeking more information about the pump…and a potential petroleum museum interested in adding the Wayne pump to its collection. Insights are welcomed in comment section below.

Learn more early transportation and gasoline pump history in First Gas Pump and Service Station and Coin-Operated Gas Pumps.

Wayne Fueling Systems

History from the former Wayne Oil Tank Company, today still operating as Wayne Fueling Systems:

Wayne has been shaping the retail and fleet fueling industry since we designed our first pump in 1891. We were known as the Wayne Oil Tank Company back then, and from the very beginning we were developing a reputation for quality.

Trade show display for Wayne Oil Tank and Pump Company equipment, showing gasoline and oil pumps. Sign for Wayne Oil Tank & Pump Co. in background. Handwritten note on back: “Service stations, 1910. Gasoline pump.” Photo courtesy Detroit Public Library.

In fact, this inaugural product won the distinction “The Best Self Measuring Oil Pump” at the Columbian Exposition in Chicago just two years later. Once the motor vehicle entered the scene, our purpose and mission was solidified – to create a reliable, accurate way for motorists to refuel cars...Learn more at About Wayne Fueling Systems.

_______________________

Recommended Reading: Pump and Circumstance: Glory Days of the Gas Station (1993). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

_______________________

The American Oil & Gas Historical Society preserves U.S. petroleum history. Please become an AOGHS supporter and help maintain this energy education website and expand historical research. For more information, contact bawells@aoghs.org. Copyright © 2024 Bruce A. Wells. All rights reserved.

Citation Information – Article Title: “Wayne’s Self-Measuring Pump.” Authors: B.A. Wells and K.L. Wells. Website Name: American Oil & Gas Historical Society. URL: https://aoghs.org/transportation/waynes-self-measuring-pump. Last Updated: May 11, 2024. Original Published Date: July 14, 2021.

(2000); Story of the Typewriter, 1873-1923 (2019); Myth, Legend, Reality: Edwin Laurentine Drake and the Early Oil Industry

(2009). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.