by Bruce Wells | Dec 14, 2025 | Petroleum Art

Cartographer visited petroleum boom towns to draw popular bird’s-eye views.

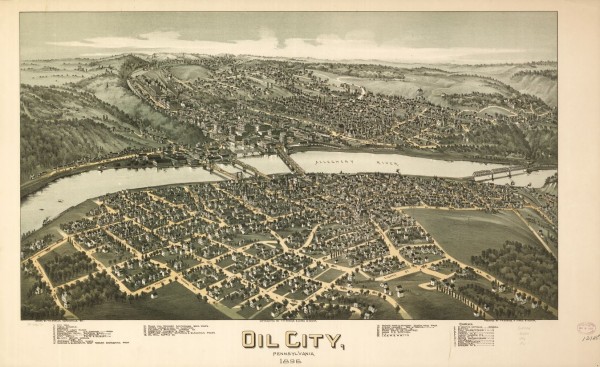

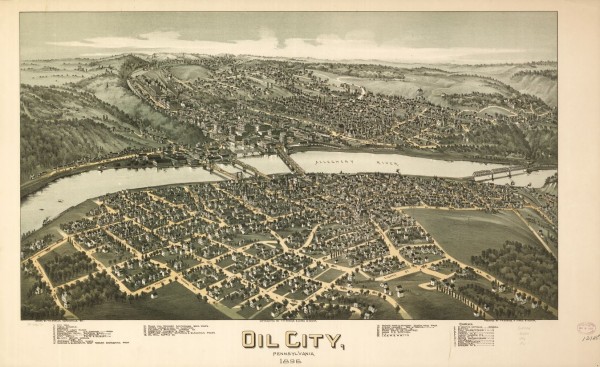

Thaddeus M. Fowler created detailed, panoramic maps of America’s earliest petroleum boom towns during the late nineteenth and early twentieth centuries. His popular cartographic depictions of oil patch communities in Pennsylvania, Oklahoma, and Texas offered “aero views” seemingly drawn from great heights.

More than 400 Thaddeus Fowler panoramas have been identified. There are 324 in the Library of Congress, including this one of Oil City, Pennsylvania, in 1896. Source: Library of Congress Geography and Map Division, Washington, D.C.

Fowler has the largest number of panoramic maps in the collection of the Library of Congress (LOC) in Washington, D.C. His hand-drawn lithographs have fascinated viewers since the Victorian Age. Being depicted in one of Fowler’s maps, also known as “bird’s-eye views,” was a matter of civic pride for many community leaders. (more…)

by Bruce Wells | Dec 2, 2025 | Petroleum Pioneers

The lucky life of John Steele and America’s earliest oil wealth.

John Washington Steele’s good fortune began on December 10, 1844, when Culbertson and Sarah McClintock adopted him as an infant. The McClintocks also adopted his sister Permelia, bringing both home to the farm along Oil Creek in Venango County, Pennsylvania.

Fifteen years later, the U.S. petroleum industry began with a 69.5-foot-deep oil discovery at nearby Titusville, the first oil well drilled commercially for distilling into kerosene (also called coal oil).

Pennsylvania petroleum reserves revealed at Oil Creek made the widow McClintock a fortune in royalties. When she died in a kitchen fire in 1864, Mrs. McClintock left her oil wealth to her only surviving child, Johnny, who inherited $24,500 at age 20.

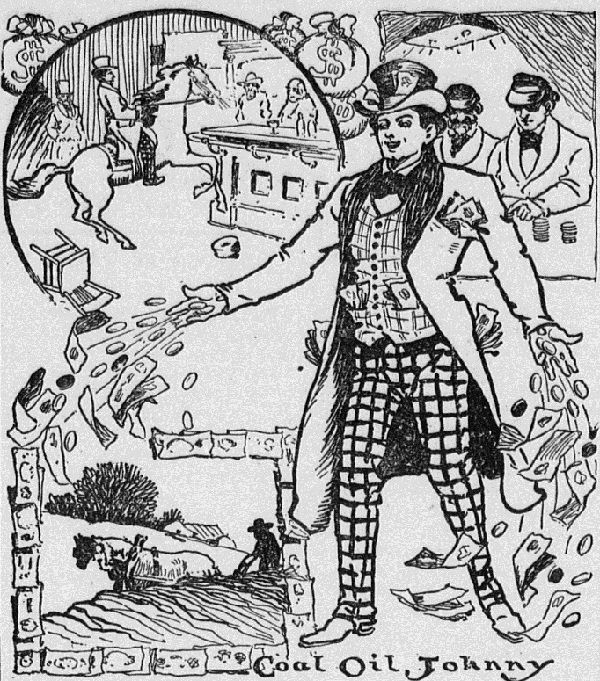

John Washington Steele of Venango County, Pennsylvania, inherited oil riches.

Johnny also inherited his mother’s 200-acre farm along Oil Creek between the now Rynd Farm and the small community of Rouseville, south of 15-miles Titusville. The farm already included 20 producing oil wells yielding $2,800 in royalties every day.

Rouseville was where future muckraking journalist Ida Minerva Tarbell (1857-1944) lived in 1861, when a gushing well erupted into flames — resulting in an early petroleum industry tragedy (see Rouseville 1861 Oil Well Fire).

Legendary Extravagance

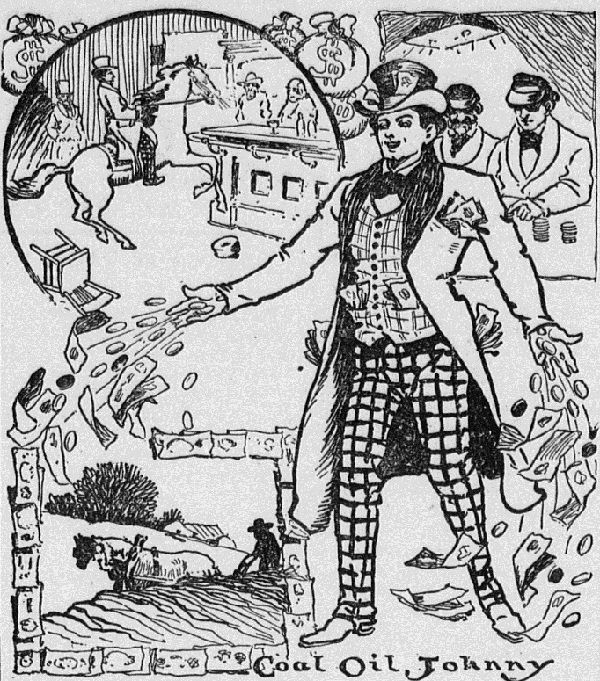

“Coal Oil Johnny” Steele would earn his famous name in 1865 — after less than one year of extravagance, according to the New York Times.

“In his day, Steele was the greatest spender the world had ever known,” the newspaper proclaimed. “He threw away $3,000,000 in less than a year.”

Philadelphia journalists coined the name “Coal Oil Johnny” for him, reportedly because of his attachment to a custom carriage that had black oil derricks spouting dollar symbols painted on its red doors. He later confessed in his autobiography:

I spent my money foolishly, recklessly, wickedly, gave it away without excuse; threw dollars to street urchins to see them scramble; tipped waiters with five and ten dollar bills; was intoxicated most of the time, and kept the crowd surrounding me usually in the same condition.

“Before J.R. Ewing, or the Beverly Hillbillies, or even John D. Rockefeller, there was Coal Oil Johnny,” noted a 2010 article in The Atlantic.

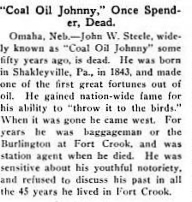

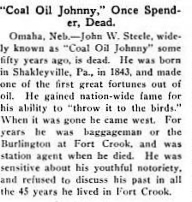

Such wealth could not last forever, but the rise and fall of Coal Oil Johnny, who died in modest circumstances in 1920 at age 76, has lingered in America’s petroleum history.

In 2010, The Atlantic magazine published “The Legend of Coal Oil Johnny, America’s Great Forgotten Parable,” an article sympathetic to his riches-to-rags story. It describes the country’s fascination with the earliest economic booms brought by “black gold” discoveries in Pennsylvania.

“Before J.R. Ewing, or the Beverly Hillbillies, or even John D. Rockefeller, there was Coal Oil Johnny,” noted the October 18 feature story. “He was the first great cautionary tale of the oil age — and his name would resound in popular culture for more than half a century after he made and lost his fortune in the 1860s.”

Refurbished boyhood home of “Coal Oil Johnny” at Oil Creek State Park (and train station) north of Rouseville, Pennsylvania. Photo by Bruce Wells.

For generations after the peak of his career, Johnny was still so famous that any major oil strike — especially the January 1901 gusher at Spindletop Hill in Beaumont, Texas — “brought his tales back to people’s lips,” noted the magazine article, citing Brian Black, a historian at Pennsylvania State University.

“It was wealth from nowhere,” Black explained. “Somebody like that was coming in without any opportunity or wealth and suddenly has a transforming moment. That’s the magic and it transfers right through to the Beverly Hillbillies and the rest of the mythology.”

John W. Steele, who “made one of the first great fortunes out of oil,” died in 1920 in Nebraska.

“Coal Oil Johnny” was a legend, and like all legends, “he became a stand-in for a constellation of people, things, ideas, feelings and morals – in this case, about oil wealth and how it works,” he added.

“He made and lost this huge fortune – and yet he didn’t go crazy or do anything terrible. Instead, he ended up living a regular, content life, mostly as a railroad agent in Nebraska,” the 2010 Atlantic article concluded. “Surely there’s a lesson in that for the millions who’ve lost everything in the housing boom and bust.”

John Washington Steele’s Venango County home, relocated and restored by Pennsylvania’s Oil Region Alliance of Business, Industry & Tourism, stands today in Oil Creek State Park, just off Route 8, north of Rouseville.

On Route 8 south of Rouseville is the still-producing McClintock No. 1 oil well. “This is the oldest well in the world that is still producing oil at its original depth,” proclaims the Alliance. “Souvenir bottles of crude oil from McClintock Well Number One are available at the Drake Well Museum, outside Titusville.”

_______________________

Recommended Reading: The Legend of Coal Oil Johnny (2007); Cherry Run Valley: Plumer, Pithole, and Oil City, Pennsylvania, Images of America (2000); Western Pennsylvania’s Oil Heritage (2008). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

_______________________

The American Oil & Gas Historical Society (AOGHS) preserves U.S. petroleum history. Please become an AOGHS annual supporter and help maintain this energy education website and expand historical research. For more information, contact bawells@aoghs.org. Copyright © 2025 Bruce A. Wells. All rights reserved.

Citation Information – Article Title: Legend of “Coal Oil Johnny.” Authors: B.A. Wells and K.L. Wells. Website Name: American Oil & Gas Historical Society. URL: https://aoghs.org/petroleum-pioneers/legend-of-coal-oil-johnny. Last Updated: December 4, 2025. Original Published Date: April 29, 2013.

by Bruce Wells | Nov 28, 2025 | Petroleum Pioneers

Rise and fall of an infamous Pennsylvania boomtown.

As the Civil War ended, oil discoveries at Pithole Creek in Pennsylvania created a headline-making boomtown for the young petroleum industry. As wells reached deeper into geological formations, the first gushers arrived — adding to “black gold” fever sweeping the country.

America’s oil production began in 1859 when Edwin L. Drake completed the first commercial well at Titusville, Pennsylvania. Drilled near natural oil seeps, his oilfield discovery at a depth of 69.5 feet led to a rush of exploration in the remote Allegheny River Valley.

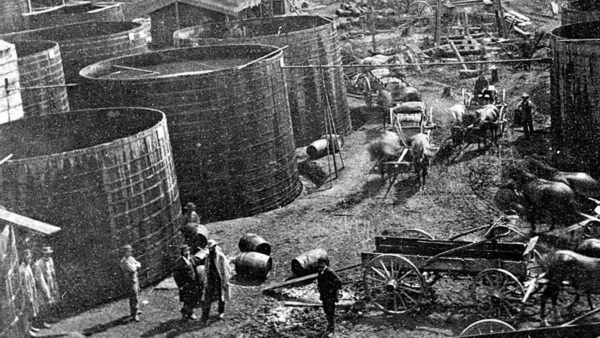

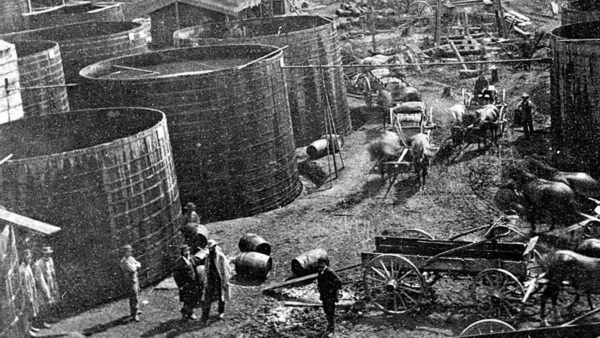

The new petroleum industry’s transportation infrastructure struggled as oil tanks crowded Pithole, Pennsylvania. In 1865, the first oil pipeline linked an oil well to a railroad station about five miles away. Photo by the “Oil Creek Artist,” John Mather, courtesy Drake Well Museum.

In 1864, businessman Ian Frazier found success along Cherry Creek, another small watercourse with signs of oil. After making a quick $250,000, Frazier looked for another opportunity for providing oil to new Pittsburgh refineries making kerosene for lamps.

Frazier hired a diviner to search along Pithole Creek, which smelled like “sulfur and brimstone,” according to historian Douglas Wayne Houck. “He went to the creek and followed the diviner around until the forked twig dipped, pointing to a specific spot on the ground,” Houck noted in 2014.

Although exploration techniques would improve, the science of petroleum geology was still in the future. Oil companies (and soon natural gas) had already begun drilling the “dry holes.”

Gusher at Pithole Creek

The first well of Ian Frazier’s United States Oil Company found no oil. A second well — drilled using the same steam-powered, cable-tool technology — erupted spectacularly on January 7, 1865, producing 650 barrels of oil a day. The Frazier well, the first U.S. oil gusher, brought a flood of drillers and speculators to Pithole Creek.

Two more wells erupted black geysers on January 17 and January 19, each flowing at about 800 barrels of oil a day (the invention of a practical blowout preventer was still half a century away). United States Oil Company subdivided its property and began selling lots for $3,000 per half-acre plot.

The Titusville Herald proclaimed Pithole as having “probably the most productive wells in the oil region of Pennsylvania, Houck explained in his Energy & Light in Nineteenth-Century Western New York. Fortunes were being made and lost in the oil regions (see the Legend of “Coal Oil Johnny”).

As the news spread through Venango County, “everyone came to the Pithole area to try their luck,” noted one reporter. Many were Confederate and Union war veterans. And as more successful wells came in, about 3,000 teamsters rushed to Pithole to haul out the rapidly multiplying barrels of oil.

Managed by the Drake Well Museum, the Pithole Visitors Center includes a diorama of the vanished town. Photo by Bruce Wells.

There were many reasons behind the Pithole oil boom, including a flood of paper money at the end of the Civil War. Returning Union veterans had currency and were eager to invest — especially after reading newspaper articles about oil gushers and boomtowns. Thousands of veterans also wanted jobs after long months on army pay.

By May 1865, the town was home to 57 hotels, many shops, and its own daily newspaper. It had the third busiest post office in Pennsylvania — handling 5,500 pieces of mail a day.

Pithole’s Lady Macbeth

In December 1865, Shakespearean tragedienne Miss Eloise Bridges appeared as Lady Macbeth in America’s first famously notorious oil boomtown.

Shakespearean tragedienne Eloise Bridges appeared on the Pithole stage in 1865.

Bridges appeared at Murphy’s Theater, the biggest building in a town of more than 30,000 teamsters, coopers, lease-traders, roughnecks, and merchants. Three stories high, the building had 1,100 seats, a 40-foot stage, an orchestra, and chandelier lighting by Tiffany.

Bridges was the acclaimed darling of the Pithole stage. Eight months after she departed for new engagements in Ohio, the oilfield at Pithole ran dry; the most famous U.S. boomtown collapsed into empty streets and abandoned buildings.

Pennsylvania oil region visitors today walk the grassy streets of the first oil boom’s ghost town.

First Oil Pipeline

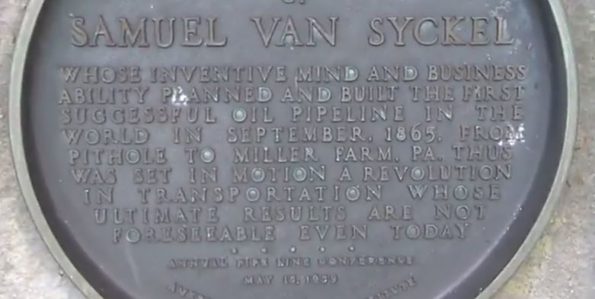

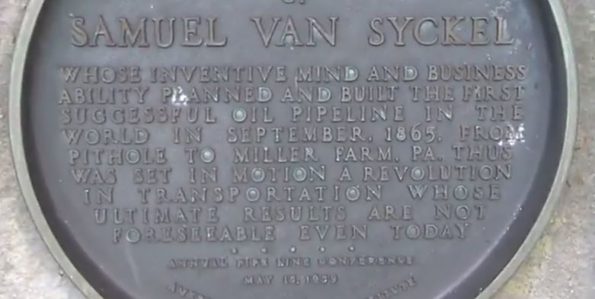

As Pithole oil tanks overflowed (and tank fires from accidents and lightning strikes increased), petroleum shipper Samuel Van Syckel conceived an infrastructure solution that became an engineering milestone.

In 1865, his newly formed Oil Transportation Association put into service a two-inch iron line linking the Frazier well to the Miller Farm Oil Creek Railroad Station, about five miles away.

The American Petroleum Institute in 1959 dedicated a plaque on the grounds of the Drake Well Museum as part of the U.S. oil centennial.

“The day that the Van Syckel pipe-line began to run oil a revolution began in the business. After the Drake well it is the most important event in the history of the Oil Regions,” declared Ida Tarbell about the technology in her 1904 book, History of the Standard Oil Company.

Widely known as a known magazine journalist and a Lincoln biographer, Tarbell grew up in the area. Her family lived in Rouseville in 1861 when a gushing well erupted into flames — an early oilfield tragedy.

With 15-foot welded joints and three 10-horsepower Reed and Cogswell steam pumps, the pipeline transported 80 barrels of oil per hour — the equivalent of 300 teamster wagons working for 10 hours. Convinced their livelihood was threatened, teamsters attempted to sabotage the oil pipeline until armed guards intervened.

Unfortunately for Van Syckel, Pithole oil storage tanks frequently caught fire even as the Frazier well production began to decline. Other wells were beginning to run dry when, in 1866, fires spread out of control and burned 30 buildings, 30 oil wells, and 20,000 barrels of oil.

Pithole City

“Pithole’s days were numbered,” concluded historian Houck about the fire, which was documented by early oilfield photographer John Mather. “Buildings were taken down and carted off. A few people hung around until 1867.”

Visitors walk the grassy paths of Pithole’s former streets and see artifacts, including antique steam boilers. Volunteers “mow the streets.” Photo by Bruce Wells.

From beginning to end, America’s famous oil boomtown had lasted about 500 days. Pithole was added to the National Register of Historic Places on March 20, 1973.

A visitors center added in 1975 contains exhibits, including a scale model of the city at its peak and a small theater. Volunteers “mow the streets” on the hillside so that tourists can stroll where the petroleum boomtown once flourished.

“Pithole City is known in the Pennsylvania oil region as the oil boomtown that vanished as quickly as it appeared,” notes the Drake Well Museum, which manages Historic Pithole City. Among the region’s earliest and most infamous investors was John Wilkes Booth (see the Dramatic Oil Company).

Oil Town Aero Views

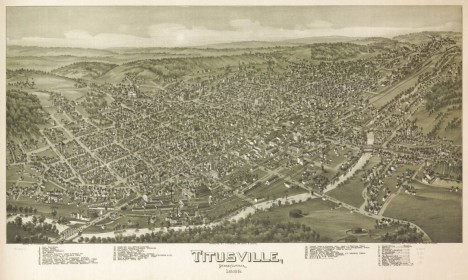

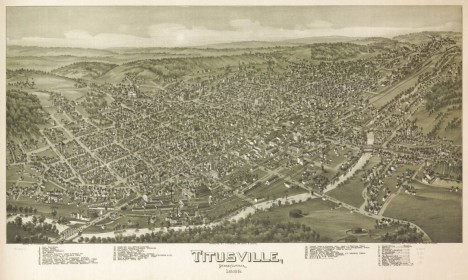

During the late 19th century, “bird’s-eye views” became a widely popular way to map U.S. cities and towns. Cartographer Thaddeus Mortimer Fowler created many of the best panoramic maps that he also called “aero views.”

The wealthy Pennsylvania oil regions attracted the attention of Fowler, who in 1885 moved his family to Morrisville, where he worked for the next 25 years.

An 1896 Pennsylvania “aero view” map by Thaddeus M. Fowler, courtesy Library of Congress.

Fowler drew maps of Titusville, Oil City, and many petroleum-related boomtowns in West Virginia, Ohio — and Texas, where he created dozens of views of cities from 1890 to 1891.

But by far, most of the Fowler maps feature Pennsylvania cities between 1872 and 1922. There are 250 examples of his work in the collection of the Library of Congress. Learn more in Oil Town “Aero Views.”

_______________________

Recommended Reading: Energy & Light in Nineteenth-Century Western New York (2014); Cherry Run Valley: Plumer, Pithole, and Oil City, Pennsylvania, Images of America (2000); The Legend of Coal Oil Johnny

(2000); The Legend of Coal Oil Johnny (2007); Myth, Legend, Reality: Edwin Laurentine Drake and the Early Oil Industry

(2007); Myth, Legend, Reality: Edwin Laurentine Drake and the Early Oil Industry (2009). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

(2009). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

_______________________

The American Oil & Gas Historical Society (AOGHS) preserves U.S. petroleum history. Please become an AOGHS annual supporter and help maintain this energy education website and expand historical research. For more information, contact bawells@aoghs.org. © 2025 Bruce A. Wells. All rights reserved.

Citation Information – Article Title: “Oil Boom at Pithole Creek.” Authors: B.A. Wells and K.L. Wells. Website Name: American Oil & Gas Historical Society. URL: https://aoghs.org/petroleum-pioneers/pithole-creek/. Last Updated: November 29, 2025. Original Published Date: March 15, 2014.