by Bruce Wells | Feb 16, 2026 | This Week in Petroleum History

February 16, 1935 – Producing States form Commission –

A multi-state government agency that would become the Interstate Oil and Gas Compact Commission was organized in Dallas, Texas, with the adoption of an “Interstate Compact to Preserve Oil and Gas.” Plans for creating the commission were developed in December 1934 at the home of Oklahoma Governor-elect Ernest W. Marland. Approved by Congress in August, the commission established its headquarters in Oklahoma City.

The Oklahoma City headquarters of the Interstate Oil and Gas Compact Commission (IOGCC) has been on property adjacent to the governor’s mansion since the 1930s.

Representatives from Colorado, Illinois, Kansas, New Mexico, Oklahoma, and Texas began planning initiatives “to conserve oil and gas by the prevention of physical waste thereof from any cause.” Oklahoma Gov. E.W. Marland, founder of Marland Oil Company in 1921, was elected the first chairman. Thirty states were active members by 1966.

“Faced with unregulated petroleum overproduction and the resulting waste, the states endorsed and Congress ratified a compact to take control of the issues,” according to IOGCC, which added the word “gas” to its name in 1991.

February 17, 1902 – Lufkin Industries founded in East Texas

The Lufkin Foundry and Machine Company was founded in Lufkin, Texas, as a repair shop for railroad and sawmill machinery. When the pine region’s timber supplies began to dwindle, the company discovered new opportunities in the burgeoning oilfields following the 1901 discovery at Spindletop Hill.

A Lufkin counterbalanced oil pump near Beaumont, Texas, in 2003. Photo by Bruce Wells.

Inventor Walter C. Trout was working for this East Texas company in 1925 when he came up with a new idea for pumping oil. His design would become an oilfield icon known by many names — nodding donkey, grasshopper, horsehead, thirsty bird, and pumpjack, among others.

By the end of 1925, a prototype of Trout’s pumping unit was installed on a Humble Oil and Refining Company well near Hull, Texas. “The well was perfectly balanced, but even with this result, it was such a funny-looking, odd thing that it was subject to ridicule and criticism,” Trout explained.

Learn more in All Pumped Up – Oilfield Technology.

February 17, 1944 – H.L. Hunt discovers First Alabama Oilfield

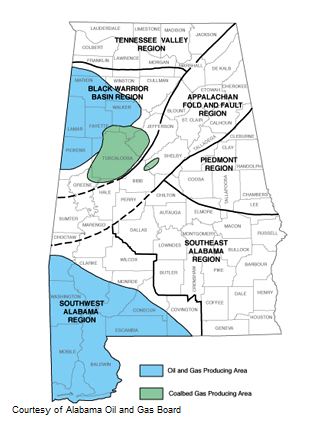

Alabama’s first oilfield was discovered in Choctaw County when independent producer H.L. Hunt of Dallas, Texas, drilled the No. 1 Jackson well. Hunt’s 1944 wildcat well revealed the Gilbertown oilfield. Prior to this discovery, 350 dry holes had been drilled in the state.

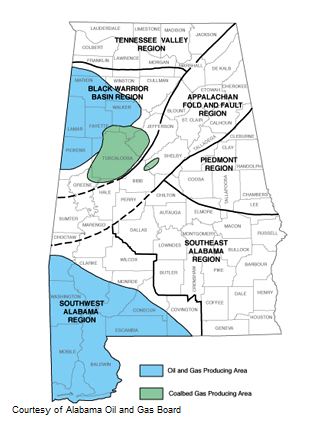

Alabama’s major petroleum-producing regions are in the west. Map courtesy Encyclopedia of Alabama.

According to research by petroleum geologist Ray Sorenson, an 1858 report first noted Alabama natural oil seeps about six miles from Oakville in Lawrence County (see Exploring Earliest Signs of Oil). Hunt’s discovery well was drilled in Choctaw County, where he revealed the Gilbertown oilfield at a depth of 3,700 feet.

Although it took 11 years for another oilfield discovery, new technologies and deeper wells in the late 1980s led to the prolific Little Cedar Creek and Brooklyn fields. By the mid-2000s, geologic assessments were underway for the potential of the shales of St. Clair and neighboring counties.

Learn more in First Alabama Oil Well.

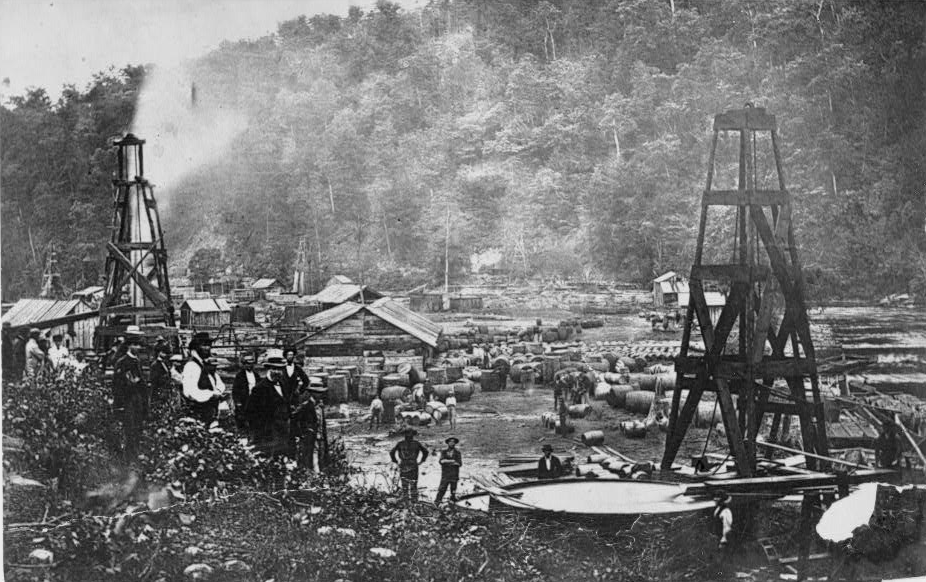

February 19, 1863 – First Pipeline Attempt to link Oilfield to Refinery

With teamsters dominating oil transportation in Pennsylvania, independent producer James L. Hutchings designed and constructed a pipeline to transport oil from a well on a farm at Oil Creek to a refinery 2.5 miles away. He had patented a rotary pump, which he used for moving the oil through two-inch piping from the Tarr Farm to the Humboldt Refinery at Oil City. His pumps worked, but the cast-iron pipeline proved impractical when the joints leaked.

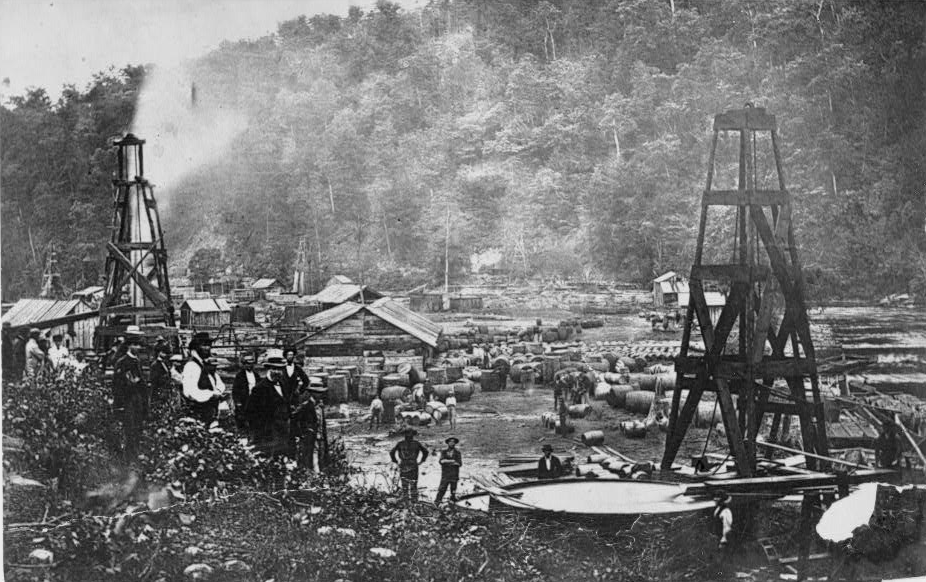

The 1863 pipeline attempt began from an oil well on the Tarr Farm (above) north of Oil City, Pennsylvania. December 1861 photograph by John A. Mather courtesy Library of Congress.

Hutchings’ concept of driving fluids with a rotary pump brought a key innovation for pipeline construction. In 1865, Samuel Van Syckel would break the teamsters’ monopoly by constructing a wrought iron pipeline with threaded joints that could transport 2,000 barrels of oil a day more than five miles — the first practical oil pipeline.

“It kind of shows you how multiple failures lead to success,” noted pipeline engineer Claudia Farrell in 2002. “The idea of driving fluids with a rotary pump sparked an innovation in the pipeline industry.”

February 20, 1959 – First LNG Tanker arrives in England

After a 27-day voyage from a processing facility just south of Lake Charles, Louisiana, the world’s first liquefied natural gas tanker arrived at Canvey Island in England’s Thames estuary, the world’s first LNG terminal. The experimental Methane Pioneer demonstrated that large quantities of LNG could be transported safely across the ocean.

The world’s first liquefied natural gas tanker, the Methane Pioneer, was a converted World War II Liberty freighter.

The first-of-its-kind vessel, a converted World War II Liberty freighter, included five 7,000-barrel aluminum tanks supported by balsa wood and insulated with plywood and urethane. Owned by Comstock Liquid Methane Corporation, the 340-foot ship kept its methane cargo refrigerated to minus 285 degrees Fahrenheit. In June 1964, the first purpose-built commercial LNG carrier — the nine LNG tank, 618-foot Methane Princess — began regular delivery to the same Canvey Island port.

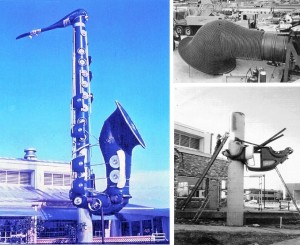

February 20, 1993 – Oil Pipe Saxophone erected in Houston

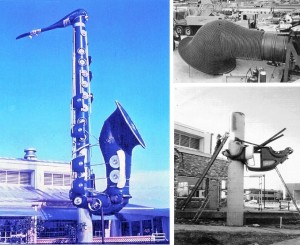

Petroleum pipelines became a work of art when offbeat Texas sculptor Bob “Daddy-O” Wade debuted his blue, 70-foot saxophone at the opening of Billy Blues Bar & Grill on Houston’s west side.

Petroleum pipeline segments contributed to a 1993 offbeat saxophone sculpture by Bob “Daddy-O” Wade for the Billy Blues Bar & Grill in Houston.

Wade transformed two 48-inch-wide pipes into the free-standing sculpture, adding an upside-down Volkswagen, chrome hubcaps, beer kegs, and assorted parts to complete his blue creation. After much debate, the Houston City Council deemed the oilfield pipeline saxophone to be art rather than signage. The Fort Worth Star-Telegram described Wade as a “connoisseur of Southwestern kitsch.”

Learn more in “Smokesax” Art has Pipeline Heart.

February 21, 1887 – Refining Process brings Riches to Rockefeller

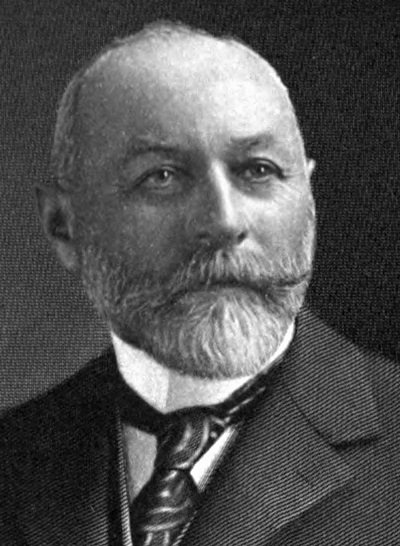

Mining engineer and chemist Herman Frasch applied to patent a new process for eliminating sulfur from “skunk-bearing oils.” The former employee of Standard Oil of New Jersey was quickly rehired by John D. Rockefeller, who owned oilfields near Lima, Ohio, that produced a thick, sulfurous oil.

Standard Oil Company, which had accumulated a 40-million-barrel stockpile of the inexpensive, sour “Lima oil,” bought Frasch’s patent for its copper-oxide refining process to “sweeten” the oil.

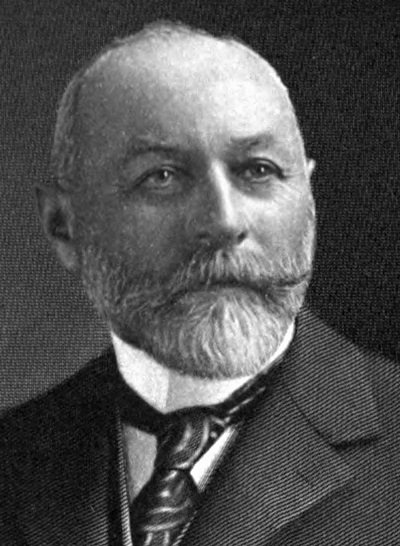

Herman Frasch (1851-1914), inventor of a key refinery process, by 1911 earned more wealth as the “Sulfur King.”

By the early 1890s, Standard Oil’s giant Whiting oil refinery east of Chicago was producing odorless kerosene from desulfurized oil, making Rockefeller another fortune.

Paid in Standard Oil shares and becoming very wealthy, Frasch moved to Louisiana — where the chemist made yet another fortune. By 1911, he was known as the “Sulfur King” after inventing a method for extracting sulfur from underground deposits by injecting superheated water into wells.

February 22, 1923 – First Carbon Black Factory in Texas

Texas granted its first permit for a carbon black factory to J.W. Hassel & Associates in Stephens County after scientists discovered carbon black increased the durability of rubber used in tires. Produced by the controlled combustion of petroleum products, carbon black could be used in many rubber products.

Early cars like the 1919 Pierce-Arrow had white rubber tires until B.F. Goodrich discovered carbon black improved durability. Photo courtesy Peter Valdes-Dapena.

Automobile tires were white until B.F. Goodrich Company in 1910 discovered that adding carbon black to the vulcanizing process improved strength and durability. An early Goodrich supplier was crayon manufacturer Binney & Smith Company (see Carbon Black and Oilfield Crayons).

_______________________

Recommended Reading: Oil in Oklahoma (1976); Lufkin, from sawdust to oil: A history of Lufkin Industries, Inc.

(1976); Lufkin, from sawdust to oil: A history of Lufkin Industries, Inc. (1982); Lost Worlds in Alabama Rocks: A Guide

(1982); Lost Worlds in Alabama Rocks: A Guide (2000); Petrolia: The Landscape of America’s First Oil Boom (2003); Natural Gas: Fuel for the 21st Century

(2000); Petrolia: The Landscape of America’s First Oil Boom (2003); Natural Gas: Fuel for the 21st Century (2015); Daddy-O’s Book of Big-Ass Art (2020); Herman Frasch — The Sulphur King (2013); The B.F. Goodrich Story Of Creative Enterprise 1870-1952

(2015); Daddy-O’s Book of Big-Ass Art (2020); Herman Frasch — The Sulphur King (2013); The B.F. Goodrich Story Of Creative Enterprise 1870-1952 (2010). Your Amazon purchases benefit the American Oil & Gas Historical Society; as an Amazon Associate, AOGHS earns a commission from qualifying purchases.

(2010). Your Amazon purchases benefit the American Oil & Gas Historical Society; as an Amazon Associate, AOGHS earns a commission from qualifying purchases.

_______________________

The American Oil & Gas Historical Society (AOGHS) preserves U.S. petroleum history. Please support AOGHS to help maintain this energy education website, a monthly email newsletter, This Week in Oil and Gas History News, and expand historical research. Contact bawells@aoghs.org. Copyright © 2026 Bruce A. Wells. All rights reserved.