by Bruce Wells | Mar 1, 2026 | Petroleum Pioneers

As drillers and speculators rushed to Spindletop Hill, the Texas Company was organized in 1902.

A series of oil and natural gas discoveries at Sour Lake, Texas — near the famous 1901 gusher at Beaumont — helped launch the major oil company Texaco.

Originally known as Sour Lake Springs because of sulfurous spring water popular for its healing properties, a series of oil discoveries brought wealth and new petroleum companies to Hardin County in southeastern Texas.

“A forest of oil well derricks at Sour Lake, Texas,” circa early1900s, courtesy the W.D. Hornaday Collection, Texas State Library and Archives Commission, Austin. Oil discoveries at the resort town northwest of the world-famous 1901 Spindletop gusher transformed the Texas Company into Texaco.

As the science of petroleum exploration and production evolved, some geologists predicted oil was trapped at a salt dome at Sour Lake, similar to that of Beaumont’s Spindletop Hill formation, which was producing massive amounts of oil.

According to Charles Warner in Texas Oil & Gas Since 1543, in November 1901 an exploratory well found “hot salt water impregnated with sulfur between 800 and 850 feet…and four oil sands about 10 feet thick at a depth of approximately 1,040 feet.”

Warner noted that the Sour Lake Springs field’s discovery well came four months later when a second attempt by the Great Western Company drilled “north of the old hotel building” in the vicinity of earlier shallow wells.

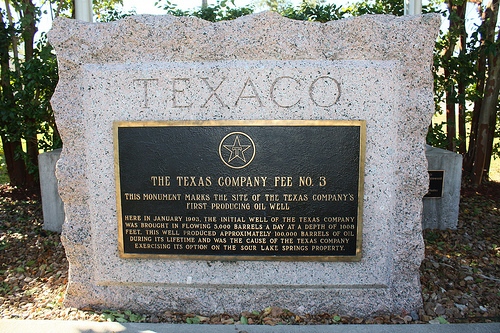

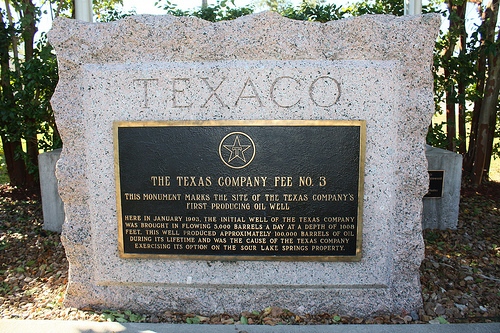

A monument marks the site where in 1903 the Fee No. 3 well flowed at 5,000 barrels of oil a day, launching the Texas Company into becoming Texaco.

“This well secured gusher production at a depth of approximately 683 feet on March 7, 1902,” Warner reported. “The well penetrated 40 feet of oil sand. The flow of oil was accompanied by a considerable amount of loose sand, and it was necessary to close the well in from time to time and bail out the sand, after which the well would respond with excellent flows.”

As more discoveries followed, Joseph “Buckskin Joe” Cullinan and Arnold Schlaet were among those who rushed to the area from their offices in Beaumont.

The Texas Company

The most significant company that started during the Spindletop oil boom was The Texas Company, according to historian Elton Gish.

“Cullinan worked in the Pennsylvania oil industry and later went to Corsicana, Texas, about 1898 when oil was first discovered in that district, where he became the most prosperous operator in the field,” reported Gish in his “History of the Texas Company and Port Arthur Works Refinery.”

Cullinan formed the Petroleum Iron Works, building oil storage tanks in the Beaumont area — where he was introduced to Schlaet. “When the Spindletop boom came in January 1901, Mr. Cullinan decided to visit Beaumont,” Gish noted. Schlaet managed the oil business of two brothers, New York leather merchants.

Named after its New York City telegraph address, the Texaco brand became official in 1959. Postcard of a Texaco service station next to a cafe in Kingman, Arizona.

“Schlaet’s field superintendent, Charles Miller, traveled to Beaumont in 1901 to witness the Spindletop activity and met with Cullinan, whom he knew from the oil business in Pennsylvania. He liked Cullinan’s plans and asked Schlaet to join them in Beaumont.”

According to Texaco, Cullinan and Schlaet formed the Texas Company on April 7, 1902, by absorbing the Texas Fuel Company and inheriting its office in Beaumont. Texas Fuel had organized just one year earlier to purchase Spindletop oil, develop storage and transportation networks, and sell the oil to northern refineries.

By November 1902, the new Texas Company was establishing a new refinery in Port Arthur as well as 20 storage tanks, building its first marine vessel, and equipping an oil terminal to serve sugar plantations along the Mississippi River.

Fee No. 3 Discovery

The Texas Company struck oil at Sour Lake Springs in January 1903, “after gambling its future on the site’s drilling rights,” the company explained. “The discovery, during a heavy downpour near Sour Lake’s mineral springs, turned the company into a major oil producer overnight, validating the risk-taking insight of company co-founder J.S. Cullinan and the ability of driller Walter Sharp.”

A Texaco station was among the 2012 indoor exhibits featured at the National Route 66 Museum in Elk City, Oklahoma. Photo by Bruce Wells.

Their 1903 Hardin County discovery at Sour Lake Springs — the Fee No. 3 well — flowed at 5,000 barrels a day, securing the Texas Company’s success in petroleum exploration, production, transportation, and refining. Sharp founded the Sharp-Hughes Tool Company in 1908 with Howard Hughes Sr.

High oil production levels from the Sour Lake field and other successful wells in the Humble oilfield (1905) secured the company’s financial base, according to L. W. Kemp and Cherie Voris in the Handbook of Texas Online.

“In 1905 the Texas Company linked these two fields by pipelines to Port Arthur, ninety miles away, and built its first refinery there. That same year the company acquired an asphalt refinery at nearby Port Neches,” the authors noted.

“In 1908 the company completed the ambitious venture of a pipeline from the Glenn Pool, in the Indian Territory (now Oklahoma), to its Southeast Texas refineries,” added Kemp and Voris.

Telegraph Address: Texaco

As early as 1905, the Texas Company had established marketing facilities not only throughout the United States but also in Belgium, Luxembourg, and Panama.

The Texas Company registered “Texaco” as a trademark in 1909.

The telegraph address for the company’s New York office is “Texaco” — a name soon applied to its products. The company registered its first trademark, the original red star with a green capital letter “T” superimposed on it in 1909. The letter remained an essential component of the logo for decades.

In August 1926, the Texas Corporation incorporated in Delaware (from Texas) and by an exchange of shares acquired outstanding stock of The Texas Company, which was dissolved the next year.

The new corporation became the parent company of numerous “Texas Company” — Texaco — entities and other subsidiaries, according to Jim Hinds of Columbus, Indiana (see Histories of Indian Refining, Havoline, and Texaco). By 1928, Texaco operated more than 4,000 gasoline stations in 48 states. It already was a major oil company when it officially renamed itself Texaco in 1959.

1987 Bankruptcy

Texaco lost a 1985 court battle following its purchase of Getty Oil Company. In February 1987 a Texas court upheld the decision against Texaco for having initiated an illegal takeover of Getty Oil after Pennzoil had made a bid for the company. Texaco filed for bankruptcy in April 1987.

The companies settled their historic $10.3 billion legal battle for $3 billion when Pennzoil agreed to drop its demand for interest. The Los Angeles Times reported the compromise was vital for Texaco emerging from bankruptcy, a haven sought to stop Pennzoil from enforcing the largest court judgment ever awarded at the time.

On October 9, 2001, Chevron and Texaco agreed to a merger that created ChevronTexaco — renamed Chevron in 2005. Although the Sour Lake Springs oil boom was surpassed by other Texas discoveries, it has remained the birthplace of Texaco.

Learn more about southeastern Texas petroleum history in Spindletop creates Modern Petroleum Industry and Prophet of Spindletop.

_______________________

Recommended Reading: The Texaco Story, The First Fifty Years 1902 – 1952 by Texas Company (1952). Texaco’s Port Arthur Works, A Legacy of Spindletop and Sour Lake (2003); Giant Under the Hill: A History of the Spindletop Oil Discovery (2008). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

(2008). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

_______________________

The American Oil & Gas Historical Society (AOGHS) preserves U.S. petroleum history. Please support AOGHS to help maintain this energy education website, a monthly email newsletter, This Week in Oil and Gas History News, and expand historical research. Contact bawells@aoghs.org. Copyright © 2026 Bruce A. Wells.

Citation Information – Article Title: “Sour Lake produces Texaco.” Authors: B.A. Wells and K.L. Wells. Website Name: American Oil & Gas Historical Society. URL: https://aoghs.org/petroleum-pioneers/sour-lake-produces-texaco. Last Updated: February 28, 2026. Original Published Date: April 5, 2014.

by Bruce Wells | Feb 21, 2026 | Petroleum History Almanac

Famed lawman and wife gambled on Kern County oil leases.

Old West lawman and gambler Wyatt Earp and his wife Josie in 1920 bet oil could be found on a barren piece of California scrub land. A century later, his Kern County lease still paid royalties.

Ushered into modest retirement by notoriety, Mr. and Mrs. Wyatt Earp were known — if not successful — entrepreneurs with abundant experience running saloons, gambling houses, bordellos (Wichita, Kansas, 1874), real estate, and finally western mining ventures.

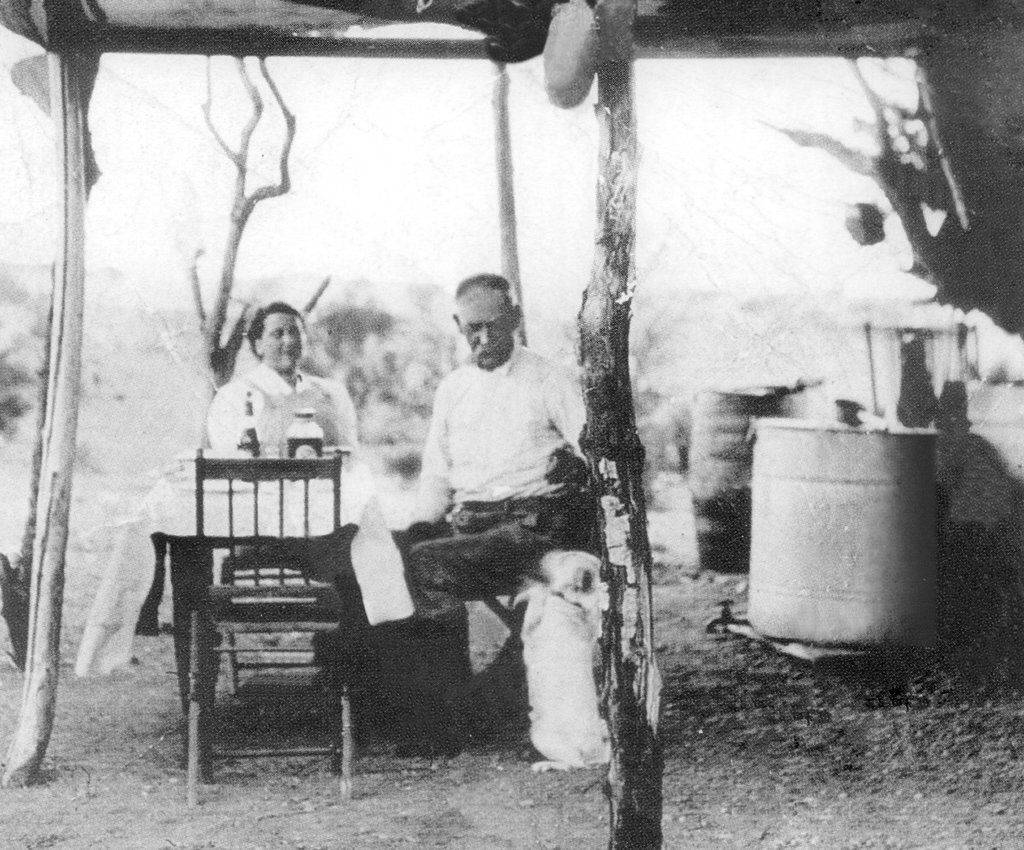

Circa 1906 photo of Wyatt Earp and wife Josie at their mining camp with dog “Earpie.”

Quietly retired in California, the couple alternately lived in suburban Los Angeles or tended to gold and copper mining holdings at their “Happy Days” camp in the Whipple Mountains near Vidal. Josephine “Josie” Marcus Earp had been by Wyatt’s side since his famous 1881 O.K. Corral gunfight in Tombstone, Arizona.

Also in California, Josie’s younger sister, Henrietta Marcus, had married into wealth and thrived in Oakland society while Josie and Wyatt roamed the West. “Hattie” Lehnhardt had the genteel life sister Josie always wanted but never had. When Hattie’s husband Emil died by suicide in 1912, the widow inherited a $225,000 estate.

Money had always been an issue between the Earps, according to John Gilchriese, amateur historian and longtime collector of Earp memorabilia.

Josie liked to remind Wyatt he had once employed a struggling gold miner — Edward Doheny — as a faro lookout (armed bouncer) in a Tombstone saloon. Doheny later drilled for oil and discovered the giant Los Angeles oilfield in the early 1880s.

The Los Angeles field launched Southern California’s petroleum industry, creating many unlikely oil millionaires — including local piano teacher Emma Summers, whose astute business sense earned her the title “Oil Queen of California.”

In addition to oilman Doheny, Earp socialized with prominent Californians like George Randolph Hearst (father of San Francisco Examiner publisher William), whom he knew from mining days in Tombstone. But the former lawman’s ride into the California oil patch began in 1920 when he gambled on an abandoned placer claim.

Kern County Lease

In 1901, a petroleum exploration venture had drilled a wildcat well about five miles north of Bakersfield in Kern County. The attempt generated brief excitement, but nothing ultimately came of it. When Shasta Oil Company drilled into bankruptcy after three dry holes, the land returned to its former reputation — worthless except for sheep grazing.

Earp decided to bet on black gold where Shasta Oil had failed. But first, California required that he post a “Notice of Intent to File Prospectors Permit.” He sent his wife to make the application. But on her way to pay the fees with paperwork in hand, Josie was diverted by gaming tables. She lost all the money, infuriating Wyatt and delaying his oil exploration venture.

Earp later secured the Kern County lease claim he sought, mostly with money from his sister-in-law, Hattie Lehnhardt,

Wyatt Earp purchased a mineral lease in Kern County, PLSS (Public Land Survey System) Section 14, Township 28 South, Range 27 East.

The San Francisco Examiner declared, “Old Property Believed Worthless for Years West of Kern Field Relocated by Old-Timers.” The newspaper — describing Earp as the “pioneer mining man of Tombstone” — reported that the old Shasta Oil Company parcel had been newly assessed.

“Indications are that a great lake of oil lies beneath the surface in this territory,” the article proclaimed. “Should this prove to be the case, the locators of the old Shasta property have stumbled onto some very valuable holdings.”

Meanwhile, competition among big players like Standard Oil of California and Getty Oil energized the California petroleum market. By July 1924, Getty Oil had won the competition and began to drill on the Earp lease.

On February 25, 1926, a well on the lease was completed with production of 150 barrels of oil a day. During 1926, nine of the wells produced a total of almost 153,000 barrels of oil. “Getty has been getting some nice production in the Kern River field ever since operations were started,” reported the Los Angeles Times.

Rarely exceeding 300 barrels of oil a day, the Getty wells were not as large as other recent California discoveries (see Signal Hill Oil Boom), but they produced oil from less than 2,000 feet deep, keeping production costs low. Royalty checks would begin arriving in the mail.

With the Oil and Gas Journal reporting “Kern River Front” oil selling for 75 cents per barrel, the Earps received $3,174 from 12 active wells producing 282,116 barrels of oil from February 1927 to January 1928, according to the 2019 book A Wyatt Earp Anthology: Long May His Story Be Told.

At age 78, Wyatt Earp’s oil gamble finally paid off — but there was a catch.

No Royalty Riches

Because of her gambling, Josie Earp had become so notoriously incapable of managing money that Earp gave control of the lease to her younger sister, Hattie Lehnhardt. At the same time, he directed that his wife “receive at all times a reasonable portion of any and all benefits, rights and interests.”

From February 1928 to January 1929, production from the dozen Earp wells declined to 91,770 barrels, “grossing $68,827 with Josie’s royalties amounting to a mere $1,032,” noted the anthology’s editors.

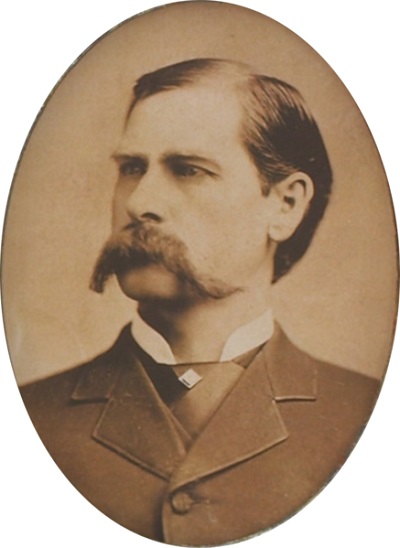

Circa 1887 portrait of Wyatt Earp at about 39 years old.

With that, Earp’s venture in the Kern County petroleum business became a footnote to his legend, already well into the making. By the time of his death on January 13, 1929, his gamble on oil, still known as the Lehnhardt Lease, had paid Josie a total of almost $6,000.

The disappointing results would prompt Josie to write, “I was in hopes they would bring in a two or three hundred barrel well. But I must be satisfied as it could have been a duster, too.”

When benefactor Hattie Lehnhardt died in 1936, her children (and some litigation) put an end to the 20 percent of the 7.5 percent of the Getty Oil royalties formerly paid to their widowed aunt Josephine. Eight years later, when Josephine died, she left a total estate of $175, including a $50 radio and a $25 trunk.

The Lehnhardt lease in Kern County would remain active. From January 2018 to December 2022, improved secondary recovery in the Lehnhardt oil properties of the California Resources Production Corporation produced 440,560 barrels of oil, according to records at ShaleXP.

Kern County Museums

Beginning in 1941, the Kern County Museum in Bakersfield has educated visitors with petroleum exhibits on a 16-acre site just north of downtown. The museum offers “Black Gold: The Oil Experience,” a permanent $4 million science, technology, and history exhibition.

The museum also preserves a large collection of historic photographs.

A roughneck monument with a 30-foot-tall derrick was dedicated in Taft, California, in 2010. Photo courtesy West Kern Oil Museum.

In Taft, the West Kern Oil Museum also has images from the 1920s showing more than 7,000 wooden derricks covering 21 miles in southwestern Kern County, according to Executive Director Arianna Mace.

Run almost entirely by volunteers — and celebrating its 50th anniversary in 2023 — the oil museum collects, preserves, and exhibits equipment telling the story of the Midway-Sunset field, which, by 1915, produced half of the oil in California. The state led the nation in oil production at the time.

Since 1946, Taft residents have annually celebrated “Oildorado.” The community in 2010 dedicated a 30-foot Oil Worker Monument with a derrick and bronze sculptures of Kern County petroleum pioneers.

Both Kern County museums played credited roles in the 2008 Academy Award-winning movie “There Will Be Blood.” Production staff visited each museum while researching realistic California wooden derricks and oil production machinery. During a visit to the West Kern Oil Museum, the film’s production designer purchased copies of authentic 1914 cable-tool derrick blueprints.

______________________

Recommended Reading: A Wyatt Earp Anthology: Long May His Story Be Told (2019); Black Gold in California: The Story of California Petroleum Industry  (2016); Early California Oil: A Photographic History, 1865-1940

(2016); Early California Oil: A Photographic History, 1865-1940 (1985); Pico Canyon Chronicles: The Story of California’s Pioneer Oil Field

(1985); Pico Canyon Chronicles: The Story of California’s Pioneer Oil Field (1985); Black Gold, the Artwork of JoAnn Cowans

(1985); Black Gold, the Artwork of JoAnn Cowans (2009). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

(2009). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

_______________________

The American Oil & Gas Historical Society (AOGHS) preserves U.S. petroleum history. Please support AOGHS to help maintain this energy education website, a monthly email newsletter, This Week in Oil and Gas History News, and expand historical research. Contact bawells@aoghs.org. Copyright © 2026 Bruce A. Wells.

Citation Information – Article Title: “Wyatt Earp’s California Oil Wells.” Authors: B.A. Wells and K.L. Wells. Website Name: American Oil & Gas Historical Society. URL: https://aoghs.org/oil-almanac/wyatt-earps-california-oil-wells. Last Updated: February 19, 2026. Original Published Date: October 30, 2013.

(2008). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.