America’s first unsuccessful well drilled for oil achieved many petroleum industry “firsts” in 1859.

Oil and natural gas exploration and production technologies began with the earliest wells of the mid-19th century in northwestern Pennsylvania. Just four days after America’s first commercial oil well of August 27, 1859, a second attempt nearby resulted in the first “dry hole” for the new U.S. petroleum industry.

Edwin L. Drake drilled the first U.S. oil well specifically seeking oil at a creek near Titusville, Pennsylvania. His historic feat included inventing the method of driving a pipe downhole to protect the integrity of the well bore. The former railroad conductor borrowed a kitchen water pump to produce the first barrel of oil.

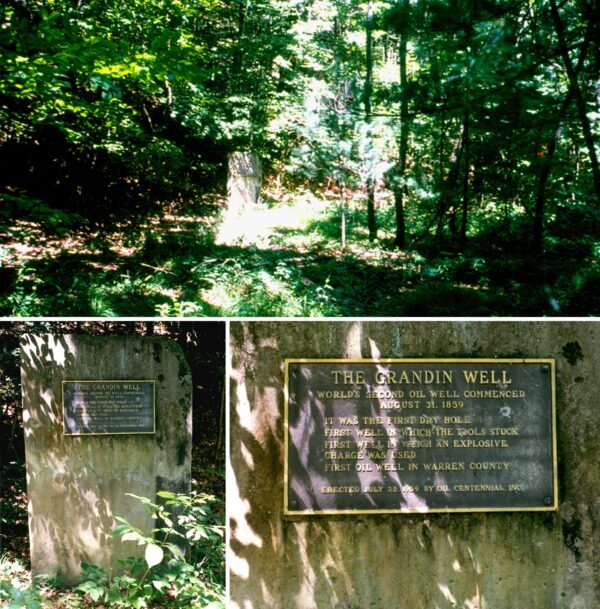

Historical marker near U.S. 62 at Tidioute, Pennsylvania, commemorates the well site of America’s first dry hole with a 1959 centennial monument to John L. Grandin’s drilling effort. Photos from a 1996 field trip, courtesy William R. Brice, PhD, Professor-Emeritus of Geology & Planetary Science at the University of Pittsburgh at Johnstown.

Although Drake’s headline-making discovery at Oil Creek launched an industry, an August 31 well would achieve far lesser known milestones. It was on that day that 22-year-old John Livingston Grandin began drilling America’s second well to be drilled for petroleum.

Today, visitors to the scenic Allegheny National Forest Region on U.S. 62 near Tidioute, Pennsylvania, will discover this Warren County roadside marker.

Firsts of the Second U.S. Well

Despite not finding the oil-producing formation (the Venango Sands), the Grandin well produced technology firsts for the young U.S. exploration and production industry, including:

♦ First dry hole,

♦ first well in which tools stuck,

♦ first well “shot” with an explosive charge.

Two days after “Drake’s Folly” at Titusville surprised everybody by producing commercial amounts of oil from a depth of 69.5 feet, the news arrived at a general store in Tidioute, 20 miles away. With each barrel of oil reportedly selling for 75 cents, John Grandin, the owner’s son and an aspiring entrepreneur, saw an opportunity.

Growing demand for a cheap fuel for lamps, led to early Pittsburgh refineries seeking oil for making kerosene.

Grandin knew of petroleum seeps on Gordon Run of the nearby Campbell Farm and rode south of town to buy the land. He bought 30 acres surrounding the oil spring at $10 per acre.

Within a day he had employed blacksmith Henry H. Dennis, said to be “the handiest man in the region,” to “kick down” a well using the time-honored spring-pole method.

Drilling with this simple method used in ancient China, the Grandin well reached almost twice as deep as Drake’s steam-powered, cable-tool effort, which had the financial backing (and patience) of the Seneca Oil Company of Connecticut’s George Bissell and company investors.

John Livingston Grandin (1836-1912).

The Drake well had used the latest drilling technology for making hole — a cable-tool rig powered by a steam boiler and with a six-horsepower horizontal steam engine.

Exploring Drilling Technologies

For their well, Grandin and Dennis constructed a rough 20-foot derrick above a spring pole. Using a discarded tram axle, Dennis made a surprisingly workable reamer. Drilling with the axle as a chisel worked well enlarging the borehole – until it became stuck at 134 feet, “where it never saw daylight again!” as described in a contemporary account.

All attempts to retrieve the axle drill bit failed — and the drilling tool was lost down-hole for the first time. This “stuck tool” milestone remains a small but important footnote in the oil and natural gas industry’s technology history.

Even as percussion drilling evolved into steam-powered cable-tools like the one used by Drake, heavy assemblies would get jammed in the borehole and could no longer be repeatedly lifted and dropped (learn more in Fishing Petroleum Wells).

However, all was not lost at Grandin’s spring-pole well, at least as far as blacksmith Dennis was concerned.

An early technology for drilling brine wells – the “spring-pole” – was replaced by steam-powered cable-tools. Photo from “The World Struggle for Oil,” a 1924 film by the Department of the Interior.

Dennis put together several makeshift “torpedoes” charged with blasting powder and experimented with timing fuses in hopes of breaking things loose downhole. “The explosion was sensibly felt upon the surface,” noted a report of his third attempt. “Mr. Dennis says, the ground trembled like an earthquake under his feet!”

With this noteworthy effort, the Grandin well was ruined in the first recorded “shooting” of an oil well — and its first failure. The U.S. petroleum industry had its first of dry hole.

Many more U.S. drilling attempts would end like the Grandin well, especially until the new sciences of petroleum geology and petroleum engineering radically changed exploration and production methods.

Drilling would make great advances as inventions like rotary drilling (used in 1901 gusher at Spindletop Hill) allowed exploration through hard rock formations miles beneath the surface.

A 15-inch bronze sculpture by Lincoln H. Fox titled, “Dressing the Bit” was presented to President Ford at the 1975 dedication of the Permian Basin Petroleum Museum in Midland, Texas. Photo courtesy Gerald R. Ford Presidential Museum, Grand Rapids, Michigan.

Even with advances in seismic surveys, geology and petroleum engineering, more than one-third of modern exploration wells drilled — costing millions of dollars each — end up as dry holes. Of the 2,803 exploratory wells drilled in 2009, natural gas was discovered by 1,188 and oil found by 626 wells. There were 989 dry holes.

John L. Grandin eventually became successful in the oilfield service industry. In addition to his father’s store in the booming oil region, the Grandin family found wealth in the lumber industry as wooden derricks multiplied. Drilling activity in Warren County centered at Tidioute and by late summer 1860 more than 60 wells had been drilled.

Grandin Wellsite Marker

“Firsts” get the jubilees, centennials and sesquicentennials. “Seconds” get roadside markers – and even those can be very hard to find. In 1959, during the centennial of Drake’s discovery, Grandin’s well was not neglected.

In 1959, a privately funded stone monument was erected at the Warren County well site with this inscription:

THE GRANDIN WELL — Worlds second oil well, commenced August 31st 1859. It was the First Dry Hole, First Well in Which Tools Stuck; First Well in Which an Explosive Charge Was Used; First Well in Warren, County, PA. Erected July 22, 1959, by Oil Centennial Inc.

A Pennsylvania Historical and Museum Commission roadside marker also can be found on U.S. 62, four-tenths of a mile south of the Allegheny River Bridge at Tidioute in Warren County. The first U.S. oil well’s sesquicentennial in 2009 was commemorated for a week in the “Valley that Changed the World.”

In Titusville, the Drake Well Museum annually draws thousands of visitors to exhibits that celebrate the August 1859 well that did discover oil and launched a new industry.

_______________________

Recommended Reading: Drilling Technology in Nontechnical Language (2012); Myth, Legend, Reality: Edwin Laurentine Drake and the Early Oil Industry

(2009); Western Pennsylvania’s Oil Heritage

(2008). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

_______________________

The American Oil & Gas Historical Society (AOGHS) preserves U.S. petroleum history. Become an AOGHS annual supporting member and help maintain this energy education website and expand historical research. For more information, contact bawells@aoghs.org. Copyright © 2023 Bruce A. Wells. All rights reserved.

Citation Information: Article Title: “First Dry Hole.” Authors: B.A. Wells and K.L. Wells. Website Name: American Oil & Gas Historical Society. URL: https://aoghs.org/technology/first-dry-hole. Last Updated: July 14, 2023. Original Published Date: December 1, 2005.