Exploring circa 1914 oilfield production technology found hidden in Pennsylvania woods.

The search for new technologies for pumping oil from wells — pump jacks — began soon after America’s first commercial discovery in 1859 near Titusville, Pennsylvania. For that well, driller Edwin L. Drake used a common water-well hand pump from a nearby kitchen.

By the end of the 19th century, a wide variety of methods, including a system for pumping multiple wells from a single power source, helped meet growing demand for petroleum to refine into the lamp oil kerosene.

Woodland Discovery

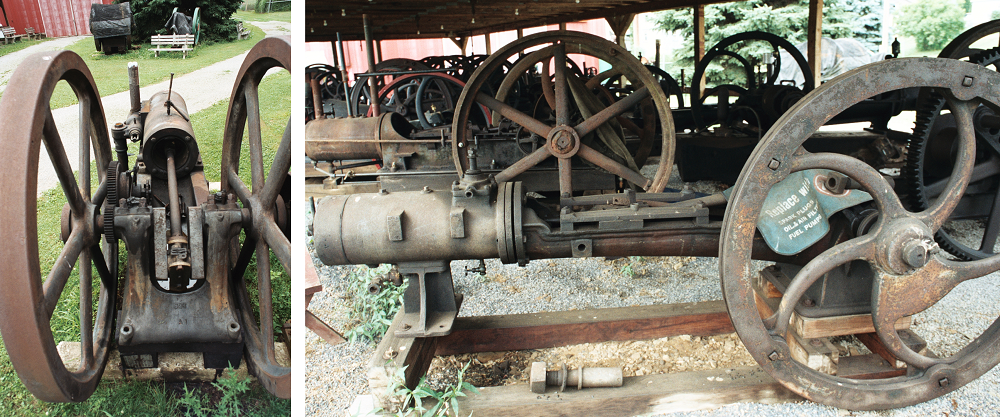

While hiking through Pennsylvania woods in 1992, photographer Patrice Gilbert discovered an abandoned circa 1910 pumping machinery in the heavily wooded area just southeast of Youngstown.

A 1992 photograph of a circa 1914 oil pumping jack, gears and flywheels. The oilfield technology artifact remained intact east of Powder Mill Creek in Butler County, Pennsylvania. Photo by Patrice Gilbert, Library of Congress Prints and Photographs Division.

The remarkably preserved steel and iron oilfield equipment probably had been too difficult or expensive to remove from the site when the well’s commercial oil production ended and it was capped.

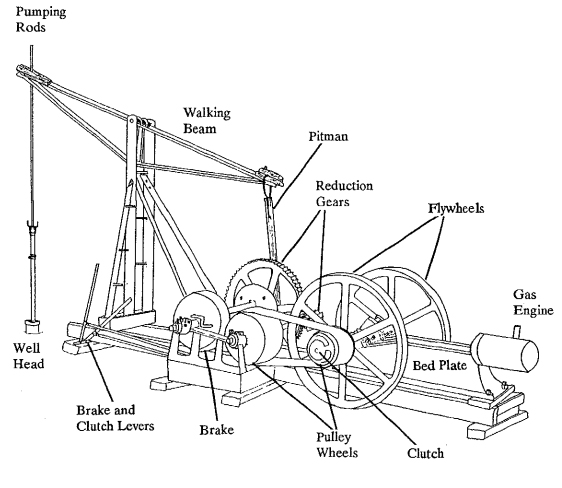

The oil pump’s advanced design, Gilbert learned from the National Park Service, was technologically significant, representing an early gear-driven pumping method designed during a time of experimentation in the early 1900s.

Bream Oil Company

The rusting pumping unit Gilbert discovered at Powder Mill Creek in Butler County recalled the many Pennsylvania oil booms along creeks that launched the U.S. industry (see Oil Boom at Pithole Creek). The county’s Bald Ridge oilfield became one of the state’s top three oil-producing counties from 1889 into the 1920s.

Other prolific wells beginning as early as 1872 brought hundreds of steam-powered, cable-tool drilling rigs as trees fell to become derricks.

On the Powder Mill site circa 1914, on land owned by a man named Heckert, a Bream Oil Company drilling rig reached 1,566 feet and struck an oil-producing geological formation — the “pay sand” — six feet thick.

Early 1900s pump technologies like this would lead to the first a prototype of a modern counterbalanced pump jack – the nodding donkey – which was invented in Lufkin, Texas, in 1925.

Bream Oil’s cable-tool derrick was removed and production began with a pump jack powered by a one cylinder, two-cycle, engine built in 1910 by the local T.W. Phillips Manufacturing Company. The 15-horsepower engine was a model equipped to run on casing head gas, which was readily available at the well.

“One-Lunger” Oilfield Engine

“The oilfield engine is usually somewhat crude and heavy and is usually manufactured for severe duty and limited maintenance,” according to Paul Harvey, founding director of Pennsylvania’s Coolspring Power Museum. “Made to quickly fill the need of the great oil boom, they were mostly of a very simple design.”

Oil producing typically was carefully watched over by a skilled “pumper,” who cleaned and oiled the high-tech equipment. A cabin would be built nearby where the oilfield worker could listen to the engine and its pump at work.

The widely used single cylinder engines, often called “one lungers” or “hit-and-miss engines,” made very distinctive sounds.

Volunteers at the Coolspring Power Museum in Pennsylvania preserve hundreds of one-cylinder engines once common in America’s oilfields. 2005 photos by Bruce Wells.

“In many pumping oilfields, these engines could be heard with a chug, chug, rattle, rattle, rattle, chug, chug, chug…and then there was a sort of a wheeze, a gasp and a cough, as though the last breath had been taken,” explained historian J.E. Brantly in his 1971 book History of Oil Well Drilling.

“At this instant, the kinetics of the flywheels took over and momentarily restored complete and serene composure,” noted the author. “Then the clamorous cycle was started over again.”

The noise was a melody to the oil well pumper’s ears — and to the producer who was producing inexpensive oil for the market, according to Brantly. Casing-head fueled engines usually were sturdy and needed less attention or repair, but the fuel was dangerously explosive but (see New London School Explosion).

The Bream Oil Company well’s mechanical gear-driven apparatus was special, according to the National Park Service. The circa 1900 pump design incorporated many elements of modern counter-balanced pump units.

The well’s Phillips Manufacturing Company engine worked into the 1980s. After the oil well was sealed and capped, the antique equipment – too heavy to be economically removed – was left as a rusting monument to Pennsylvania petroleum heritage.

An early pump jack on exhibit in front of the Fellows Hotel at the Kern County Museum, Bakersfield, California, in 2005.

Today in the 33 petroleum-producing states, oil well pumping jacks — “nodding donkeys” — can be seen bobbing up and down in America’s oilfields. The modern counter-balanced pump jack, invented in Lufkin, Texas, in 1925 by Walter Trout, works on the same principle as the old jacks of yesteryear.

Learn more in All Pumped Up – Oilfield Technology.

Gilbert’s old oil patch photograph, now in the collection of the Library of Congress, was featured in a 2015 limited-edition “Today in American Petroleum History” calendar published by the American Oil & Gas Historical Society.

_______________________

Recommended Reading: Myth, Legend, Reality: Edwin Laurentine Drake and the Early Oil Industry (2009); Artificial Lift-down Hole Pumping Systems: Conference Transcript (1984); History of Oil Well Drilling (1971). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

_______________________

The American Oil & Gas Historical Society (AOGHS) preserves U.S. petroleum history. Become an AOGHS supporting member and help maintain this energy education website and expand historical research. For more information, contact bawells@aoghs.org. © 2024 Bruce A. Wells.

Citation Information – Article Title: “Pump Jack at Powder Mill Creek.” Author: Aoghs.org Editors. Website Name: American Oil & Gas Historical Society. URL: https://aoghs.org/technology/pump-jack-at-powder-mill-creek. Last Updated: June 22, 2023. Original Published Date: June 19, 2014.