This Week in Petroleum History: June 16 – 22

June 16, 1903 – Ford Motor Company Incorporated –

After successfully testing his gasoline-powered Quadricycle in 1896, Henry Ford and a group of investors (including machinist John Dodge) filed articles of association for the Ford Motor Company. Ford’s contributions included machinery, drawings, and several patents. The first sale was a Ford Model A to a Chicago physician in July as the Detroit-based automaker began ordering carriages, wheels, and tires for a low-cost car that would become the Model T by 1908, according to the Henry Ford Heritage Association (HFHA).

June 18, 1889 – Standard Oil of New Jersey adds Indiana

Standard Oil Company of New Jersey incorporated a subsidiary, Standard Oil Company of Indiana, and began processing oil at its new refinery in Whiting, Indiana, southeast of Chicago. In 1910, the refinery added pipelines connecting it to Kansas and Oklahoma oilfields. When the Supreme Court mandated the break up of John D. Rockefeller’s empire in 1911, Standard Oil of Indiana emerged as an independent company. Amoco branded service stations arrived in the 1950s. Amoco merged with British Petroleum (BP) in 1998, the largest foreign takeover of a U.S. company at the time.

June 18, 1946 – Truman establishes National Petroleum Council

At the request of President Harry S. Truman, the Department of the Interior established the National Petroleum Council to make policy recommendations relating to oil and natural gas. Transferred to the new Department of Energy in 1977, the Council became a privately funded advisory committee with 200 members appointed by the Secretary of Energy. “The NPC does not concern itself with trade practices, nor does it engage in any of the usual trade association activities,” notes the NPC, which held its 134th meeting on April 23, 2024, in Washington, D.C.

June 18, 1948 – Service Company celebrates 100,000th Perforation

Fifteen years after its first well-perforation job, the Lane-Wells Company returned to the well at Montebello, California, to perform its 100,000th perforation. The return to Union Oil Company’s La Merced No. 17 well included a ceremony hosted by Walter Wells, chairman and company co-founder.

Los Angeles headquarters of Lane-Wells by architect William Mayer, completed in 1937. Photo courtesy Water and Power Associates.

In 1930, Wells and oilfield tool salesman Bill Lane developed a practical multiple-shot perforator that could shoot steel bullets through casing. After many tests, success came at the La Merced No. 17 well. By late 1935, Lane-Wells established a small fleet of trucks for well-perforation services. The company merged with Dresser Industries in 1956 and later became part of Baker-Atlas.

Learn more in Lane-Wells 100,000th Perforation.

June 20, 1977 – Oil begins Flowing in Trans-Alaska Pipeline

The Trans-Alaska Pipeline began carrying oil 800 miles from Prudhoe Bay to the Port of Valdez at Prince William Sound. The oil arrived 38 days later, culminating the world’s largest privately funded construction project. The Prudhoe Bay field had been discovered in 1968 by Atlantic Richfield and Exxon about 250 miles north of the Arctic Circle.

After years of controversy, construction of the 48-inch-wide pipeline began in April 1974. Above-ground sections of the pipeline (420 miles) were built in a zigzag configuration to allow for expansion or contraction and include heat pipes. Oil throughput of the $8 billion pipeline peaked in 1988 at just over 2 million barrels per day, according to the Energy Information Administration (EIA), adding that since 2003, deliveries have been less than 1 million barrels per day and averaged a record low of 464,748 barrels per day in 2024.

“That creates challenges for the pipeline’s operators, including the formation of ice and the buildup of wax that is in the oil on the inside pipeline wall, EIA notes. “The amount of time it takes for oil to travel the 800 miles through the pipeline from the North Slope to the Valdez port increased from 4.5 days in 1988 to about 19 days in recent years.”

Learn more in Trans-Alaska Pipeline History.

June 21, 1893 – Submersible Pump Inventor born

Armais Arutunoff, inventor of the electric submersible pump for oil wells, was born to Armenian parents in Tiflis, Russia. He invented the world’s first electrical centrifugal submersible pump in 1916. At first, Arutunoff could not find financial support for his oilfield production technology after emigrating to the United States in 1923.

Thanks to help from Frank Phillips, president of Phillips Petroleum, Arutunoff moved to Bartlesville, Oklahoma, in 1928 and established a manufacturing company. The Tulsa World described the Arutunoff pump as “An electric motor with the proportions of a slim fencepost which stands on its head at the bottom of a well and kicks oil to the surface with its feet.”

REDA Pump Company manufactured pump and motor devices — and employed hundreds during the Great Depression. The name stands for Russian Electrical Dynamo of Arutunoff, the cable address of his first company in Germany and since 1998 a subsidiary of SLB (Schlumberger).

Learn more in Inventing the Electric Submersible Pump.

June 21, 1932 – Oklahoma Governor battles “Hot Oil”

Thirty National Guardsmen marched into the Oklahoma City oilfield when Governor William H. “Alfalfa Bill” Murray took control of oil production after creating a proration board despite objections from independent producers.

The Oklahoma History Center in Oklahoma City includes petroleum equipment on display in the Devon Energy Park, which opened in 2005. Photo by Bruce Wells.

Murray declared martial law again in March 1933 to enforce his regulations preventing the sale or transport of oil produced in excess of the quota, referred to as “hot oil.”

The state legislature passed a law in April giving the Oklahoma Corporation Commission authority to enforce its rules — taking away Murray’s power to regulate the petroleum industry. The commission had been established in 1907 to regulate railroad, telephone, and telegraph companies.

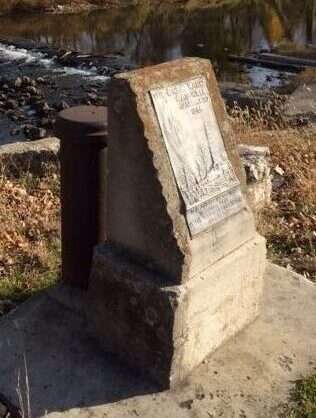

June 21, 1937 – “Great Karg Well” Marker dedicated in Ohio

Similar to the Indiana natural gas boom, discoveries in Ohio brought petroleum prosperity as evidenced by a 1937 historic marker at one well — “erected in humble pride by the people of Findlay, Ohio,” in celebration of the “Great Karg Well” that revealed a giant natural gas field in January 1886.

Marker dedicated in 1937 at the wellhead of the famous 1886 natural gas discovery at Findlay, Ohio. Photo by Michael Baker, courtesy Historical Marker Database.

“At that time gas was simply a by-product of oil drilling, and with no way to store it they ended up piping it away for free to heat homes and drive industrial machinery,” notes the historic marker inscription at the wellhead. Many companies promoted Ohio’s natural gas supplies, which “attracted glass companies from around the world” — until the gas ran out.

Learn more in Indiana Natural Gas Boom.

_______________________

Recommended Reading: From Here to Obscurity: An Illustrated History of the Model T Ford, 1909 – 1927 (1971); Standard Oil Company: The Rise and Fall of America’s Most Famous Monopoly

(2016); The Prize: The Epic Quest for Oil, Money & Power

(2008); Wireline: A History of the Well Logging and Perforating Business in the Oil Fields

(1990)

; The Great Alaska Pipeline

(1988); Artificial Lift-down Hole Pumping Systems

(1984); Oil in Oklahoma

(1976); Ohio Oil and Gas, Images of America

(2008). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

_______________________

The American Oil & Gas Historical Society (AOGHS) preserves U.S. petroleum history. Please become an AOGHS annual supporter and help maintain this energy education website and expand historical research. For more information, contact bawells@aoghs.org. Copyright © 2025. Bruce A. Wells. All rights reserved.