The science behind petroleum exploration and production — and finding oil and natural gas at greater depths.

“A good cable-tool man is just about the most highly skilled worker you’ll find,” one veteran of the oil patch noted. “Besides having a feel for the job, knowing what’s going on thousands of feet under the ground just from the movement of the cable, he’s got to be something of a carpenter, a steam-fitter, an electrician, and a damned good mechanic.” – A 1939 interview in Voices from the Oil Fields by Paul Lambert and Kenny Franks.

Petroleum exploration technologies have evolved from ancient “spring poles,” to steam-powered percussion cable-tools, to modern rotary rigs with steerable, diamond bits that can drill miles deep.

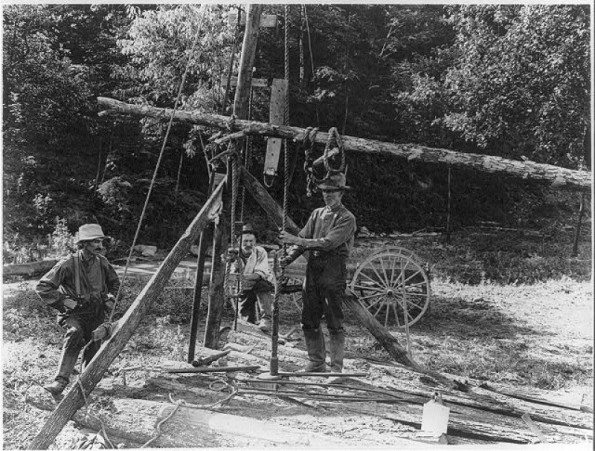

Often used for drilling brine wells, a “spring-pole” well discovered oil in Appalachia. Photo from “The World Struggle for Oil,” a 1924 film by the U.S. Department of the Interior.

“A cable tool driller knows more knots and splices than any six sailors you can find,” recorded historians Lambert and Franks in their 1984 book, a collection of 1930s Federal Writers Project interviews about oilfield life.

The book’s collection — featuring descriptions of cable-tools with giant “bull wheels” spinning off manila rope — includes many firsthand accounts of the “grueling toil, primitive living and working conditions, and ever-present danger in a time when life was cheap and oil was gold.”

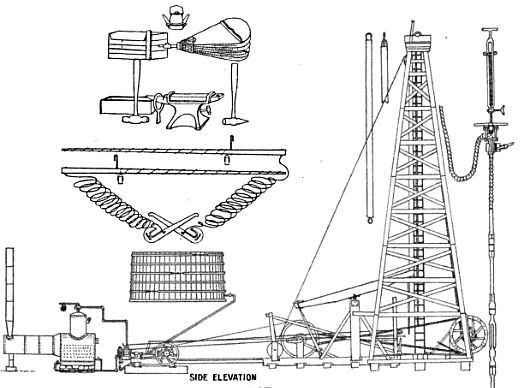

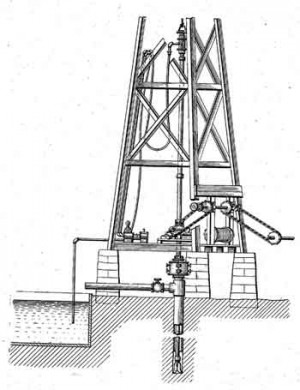

Standard cable-tool derricks stood 82 feet tall and were powered by a steam boiler and engine using a “walking beam” to raise and lower drilling tools. Image from The Oil-Well Driller, 1905.

Drilling or “making hole” began long before crude oil or natural gas were anything more than flammable curiosities found seeping from the ground.

For centuries, digging by hand or shovel were the best technologies that existed to pry into the earth’s secrets. Oil provided a balm for injuries. Natural gas seeps — when ignited — created folklore and places called “burning springs.”

Drilling technology advanced when the spring pole harnessed the resiliency of a bent tree to assist in pummeling a hole into the ground to find water.

Ancient histories record the technique, which is still used in some corners of the world. While repeatedly kicking down a stirrup was primitive and slow, the spring pole’s rope and chisel were practical drilling technologies.

The Ruffner brothers’ tools for their spring pole consisted of a manila line and a variety of chisels.

Salt was an essential commodity for preserving food and extracting it from brine was a simple process.

In 1802 in what is now West Virginia, salt brine drillers David and Joseph Ruffner took 18 months to drill through 40 feet of bedrock to a total depth of 58 feet using a spring pole.

The Ruffner brothers drilling ingenuity and innovation made the Kanawha River Valley a major salt manufacturing and distribution center in the early 1800s. Many early drilling technologies were developed there.

“The Ruffner brothers’ well was the first well known to have been ‘drilled,’ as distinct from ‘dug,’ in the Western Hemisphere,” noted J.E. Brantly in his comprehensive 1971 book, History of Oil Well Drilling.

The well’s historic significance rests on the “development of well drilling tools and practices, which became almost immediately standard equipment used by many other well drillers in the new salt industry,” Brantly explained.

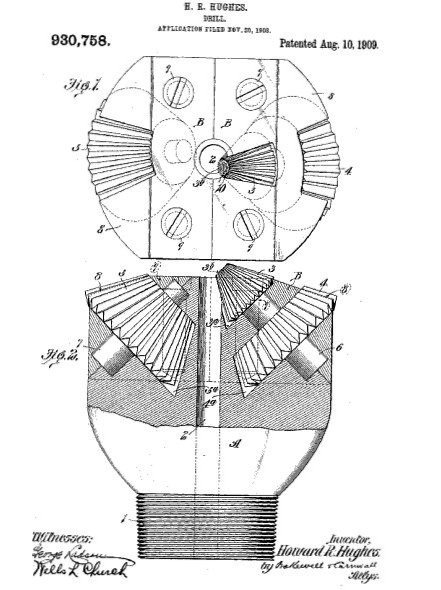

A Howard Hughes Sr. 1909 dual-cone drill bit patent would “create the cornerstone of Hughes Tool Company.”

There was money to be made from brine wells. The rapidly growing number of settlers in the frontier needed a lot of salt to preserve food.

However, sometimes a good well would be fouled with the intrusion of unsought and unwanted oil. The rainbow sheen and pungent smell of oil was bad news to brine drillers.

Chiseling Holes with Cable Tools

The advent of cable-tool drilling introduced the wooden derrick into the changing American landscape. Using the same basic notion of chiseling a hole deeper into the earth, along with adding steam power and clever mechanical engineering, wells could be drilled far more efficiently.

Frequent stops were needed to remove the chipped-away rock and other material, bail out water — and sharpen the bit. Bull wheels and hemp rope repeatedly hoisted and dropped heavy iron drill strings and a curious variety of bits deep into the borehole. Oil was still an adversary to those in search of either fresh water or brine.

However, savvy businessmen like the Ruffner brothers and Samuel Kier of Tarentum, Pennsylvania, learned to profit from this oil.

It had long been recognized that oil could be collected and used as a medicine, lubricant, and even a foul-smelling, smoky illuminant. American Indians gathered oil by using blankets to soak it up from natural seeps. The Ruffner brothers sold their oil to marketers of patent medicines and lubrication products.

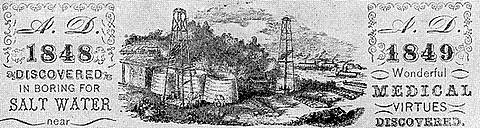

A decade before the birth of the petroleum industry, Samuel Kier of Pittsburgh, Pennsylvania, sold 50-cent, half-pint bottles of Pennsylvania “Rock Oil” proclaiming its “Wonderful Medical Virtues.” Kier’s advertisements featured wooden cable-tool derricks drilling brine wells.

Oil from natural seeps had been used as a balm by Native Americans. In 1848, Samuel Kier bottled and sold “Rock Oil” proclaiming its “Wonderful Medical Virtues.”

George Bissell became determined to make a lamp fuel from oil after seeing natural seeps at a creek in northwestern Pennsylvania. Bissell gave samples to Yale chemist Benjamin Silliman, who found the oil could be distilled into a quality kerosene illuminant. The world would soon change forever.

Bissell formed the Pennsylvania Rock Oil Company with the idea of using cable tool drilling to extract the oil beneath Oil Creek near Titusville. It worked, and the petroleum age was born.

Kier soon abandoned his patent medicine and went into the kerosene refining business, buying all the oil he could get. Edwin L. Drake’s August 27, 1859, discovery of commercial quantities of oil at 69. 5 feet brought America’s first drilling boom — and created an industry. Soon, cable-tool wooden derricks were everywhere, pounding into the earth, searching for oil.

In June 1860, J.C. Rathbone used a steam engine to drill a 140-foot-deep well on the bank of the Great Kanawha River, within the city limits of what is now Charleston, West Virginia. His discovery well produced about 100 barrels of oil a day.

In Pennsylvania, West Virginia and Ohio, the soft soil yielded to cable-tool drilling. But as wells got deeper, some drilling experts found resistant rock strata that made progress far more difficult. Sometimes the drilling stools got stuck, threatening the well. Learn more in Fishing in Petroleum Wells.

Innovative Patents

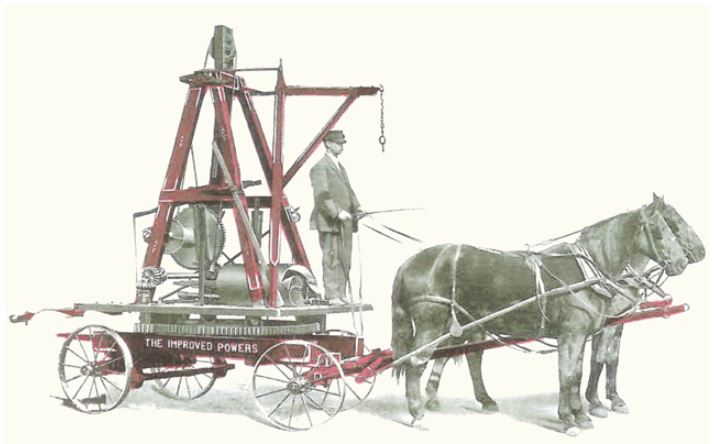

In 1895, Oscar Benjamin of Lafayette, Louisiana, patented a “Well Boring Machine,” that improved portable cable-tools drilling technology for “artesian and oil wells.” His design used a framework mounted on wheels with a hinged derrick, “adapted to swing over in transit.” When in use, the derrick would be steadied by stay-ropes, Benjamin noted in his patent (548,109).

In September 1903, Seth Powers of Stanberry, Missouri, received a U.S. patent for his “Combined Well Boring and Rock Drilling Machine,” and the Lisle Manufacturing Company was launched in Clarinda, Iowa, to produce the “One-Man Machine.”

Seth Powers manufactured a portable drilling rig for boring deeper wells. Image courtesy Superstition Mountain Museum.

Powers’ wheel-mounted framework — used primarily for water wells but capable of finding oil — included a derrick, steam-engine, and boring augers.

The earliest model was powered by a horse moving in a circle after the operator hitched it to a gearbox to rotate the entire platform, boom, and auger. The Superstition Mountain Museum of Apache Junction, Arizona, has preserved an original of this 1890 version of the Powers Well Boring Machine Rig.

By World War I, the Lisle Company manufactured a complete line of portable drilling machines that could bore up to 1,000 feet deep with the gasoline powered model.

Rotary Rigs cut Faster, Deeper

A new technology answered the call of necessity and the lure of opportunity. Rotary drilling is most often associated with the spectacular 1901 “Lucas Gusher” at Spindletop Hill near Beaumont, Texas.

Instead of the repetitive lift and drop of heavy cable-tool bits, rotary drilling introduced the hollow drill stem that enabled broken rock debris to be washed out of the borehole with re-circulated mud while the rotating drill bit cut deeper.

Rotary drilling introduced the hollow drill stem that enabled broken rock debris to be washed out of the borehole.

Rotary drilling uses fluids (drilling mud) to circulate out the rock as it is chipped away. The fluid washes out the drill hole as it goes, making the process more efficient. By applying downward pressure, drilling mud also stops an oil well from bursting forth unexpectedly – producing dangerous and wasteful gushers.

Meanwhile, grinding their way through layers of rock rather than pounding, the heavy fishtail bits made history. Rotary rigs soon became the preferred means of drilling for oil, although to this day they still share the oil patch with a few cable-tool rigs.

The record depth recorded for a cable-tool rig is 11,145 feet. On Russia’s Kola Peninsula, a rotary rig reached more than 40,000 feet after ten years of drilling.

Equipping a Rotary Rig

Today, the latest technologies are used for rotary drilling and production. John Bestoloffe in 2010 investigated the Eagle Ford shale formations in South Texas – among the most actively drilled geologic zones in the United States. He also offered basic descriptions of the technologies used to improved efficiency and safety.

Modern rotary rigs still include many of the basic components applied more than a century ago. Below are the descriptions Bestoloffe noted in his “Anatomy of an Oil Rig.”

Swivel – a big handle that holds the weight of a drill string and allows the string to rotate, making a pressure tight seal on the drilling hole.

Drill String – made up of the drill pipe (normally sections of drill pipe are about 30 feet and are connected together) and drill collars which fit around the pipe in order to put weight on the drill bit.

Howard Hughes Sr. of Houston, Texas, received a patent in 1909 for a drill that “relates to boring drills.”

Drill Bit – the very end of the drill, which is capable of cutting through rock. Bits come in many different sizes and shapes and can be made of various materials including diamond and carbide steel. Drill bits are specialized for different types of rock formations and drilling tasks.

Rotary or Turntable – the component that drives rotating motion by utilizing power from electric motors.

Kelly – a four or six-sided pipe that will transfer the rotary motion to the rotary table and drill string.

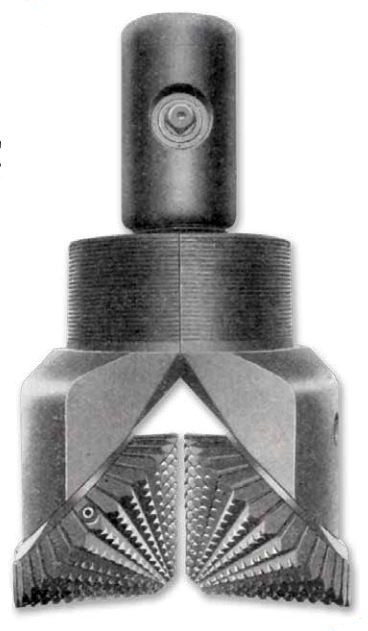

Dual-Cone Bit of Howard Hughes Sr.

Fishtail bits became obsolete in 1909 when Howard Hughes Sr. introduced the twin-cone roller bit. History remembers several men who were trying to develop better drill bit technologies, but it was Hughes who made it happen.

The Society of Petroleum Engineers (SPE) has noted that about the same time Hughes developed his bit, Granville A. Humason of Shreveport, La., patented the first cross-roller rock bit, the forerunner of the Reed cross-roller bit. Biographers note that Howard Hughes Sr. met Granville Humason in a Shreveport bar, where Humason sold his roller bit rights to Hughes for $150.

The Hughes two-cone drill bit was designated a Historic Mechanical Engineering Landmark in 2009.

The University of Texas’ Center for American History has a rare 1951 recording of Humason’s recollections of that chance meeting. Humason recalls he spent $50 of his sale proceeds at the bar during the balance of the evening.

While waiting for approval of the patent in 1909, Hughes and and business partner Walter B. Sharp had a machine shop manufacture a prototype bit to test in the field. Their secret drilling experiment took place near Houston. In June the partners loaded their newly cast steel bit on a horse-drawn wagon and took it to the Goose Creek oilfield, according to historian Donald Barlett.

After stopping at an oil well that had defied conventional drills, the men ordered field hands away and secretly brought out the bit and attached it to the pipe stem of the rotary rig. For the next 11 hours, the bit bored through 14 feet of solid rock, “a feat so miraculous for the time that drillers dubbed the mysterious device the “rock eater.”

Hughes took over the tool company after Sharp died in 1912. Rotary drilling with the new bit soon revolutionized the search for petroleum by allowing deeper wells through harder rock formations.

In 1933, Hughes engineers invented the tri-cone bit, which drilled holes straighter and faster, according to a Nicholas Lemann article in Texas Monthly.

Sharp-Hughes Tool Company manufactured its new drill bits in Houston. Circa 1915 photo courtesy Houston Public Library.

“For the 17 years that the patent on it ran (1934 through 1951) Hughes’s market share approached 100 per cent,” Lemann noted in a 1982 article. “The bit found virtually all the oil discovered in the glory days of wildcatting, and Howard Junior got to be the richest man in the world.”

Howard Hughes Jr. took the tool company public in 1972 and made $150 million, Lemann noted in his 1982 article “Texas Primer: The Hughes Drill Bit. “With the money earned from drill bits, Hughes made dozens of movies, took over Trans World Airways, “and built a good chunk of Las Vegas, among other things.”

Innovations by others accompanied the advancements in drilling time and depth. Frank and George Christensen developed the earliest diamond bit in 1941. The tungsten carbide tooth came into use in the early 1950s. The company Hughes founded would merge in 1987 with another founded in 1913 by Carl Baker – the Baker Casing Shoe Company (renamed Baker Oil Tools in 1928).

Howard Hughes Jr. will greatly expand the petroleum service company fortune created by his father, who paid $150 for the rights to the roller bit.

Learn more in Carl Baker and Howard Hughes.

In 1990, Baker Hughes purchased the Christensen company, which in 1992 resulted in the first rolling cone bit company and first diamond bit company becoming today’s Hughes Christensen, a Baker Hughes company.

To learn more about early petroleum technologies, see All Pumped Up – Oilfield Technology.

How did a derrick get its Name?

A noun commonly defined as “a hoisting apparatus employing a tackle rigged at the end of a beam,” or a “framework or tower over a deep drill hole (as of an oil well) for supporting boring tackle,” the word derrick originated in 17th century English sailors’ gallows humor.

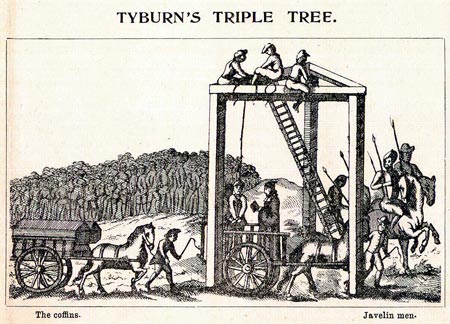

A hanging at Tyburn, about two miles from London’s Newgate prison.

Elizabethan sailors hoisting cargo from London’s Thames River docks observed that the process bore a macabre resemblance to the monthly hangings held at Tyburn, about two miles from Newgate prison. The executioner, who served Queen Elizabeth I and King James I, was Thomas Derrick, and his name became associated with dockside loading rigs.

By 1656, Thomas Blount’s Glossographia (dictionary) recorded that the term was in common use “for a hangman because one of that name was not long since a famed executioner at Tiburn.”

_______________________

Recommended Reading: Voices from the Oil Fields, 1939 (2020); History Of Oil Well Drilling (2007); Drilling Technology in Nontechnical Language

(2012); Myth, Legend, Reality: Edwin Laurentine Drake and the Early Oil Industry

(2009). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

_______________________

The American Oil & Gas Historical Society (AOGHS) preserves U.S. petroleum history. Become an AOGHS annual supporting member and help maintain this energy education website and expand historical research. For more information, contact bawells@aoghs.org. Copyright © 2023 Bruce A. Wells. All rights reserved.

Citation Information – Article Title: “Making Hole – Drilling Technology.” Authors: B.W. Wells and K.L. Wells. Website Name: American Oil & Gas Historical Society. URL: https://aoghs.org/technology/oil-well-drilling-technology. Last Updated: February 20, 2024. Original Published Date: September 1, 2006.