This Week in Petroleum History: May 5 – 11

May 5, 1889 – Construction begins on Giant Refinery –

On the southern shore of Lake Michigan near Chicago, Standard Oil Company of New Jersey began construction of its 235-acre refinery complex with advanced processing technologies. A newly patented refining method would allow the Whiting, Indiana, facility to process sulfurous “sour crude” from Lima, Ohio, oilfields.

Standard Oil of Indiana emerged as an independent company following the 1911 breakup of the Standard Oil Trust.

The refinery would be operated by a new subsidiary established in June, Standard Oil Company of Indiana. The Whiting refinery (in 2025 operated by BP) originally produced high-quality kerosene for lamps. BP completed a multi-billion dollar modernization project there in 2013.

Learn more in Standard Oil Whiting Refinery.

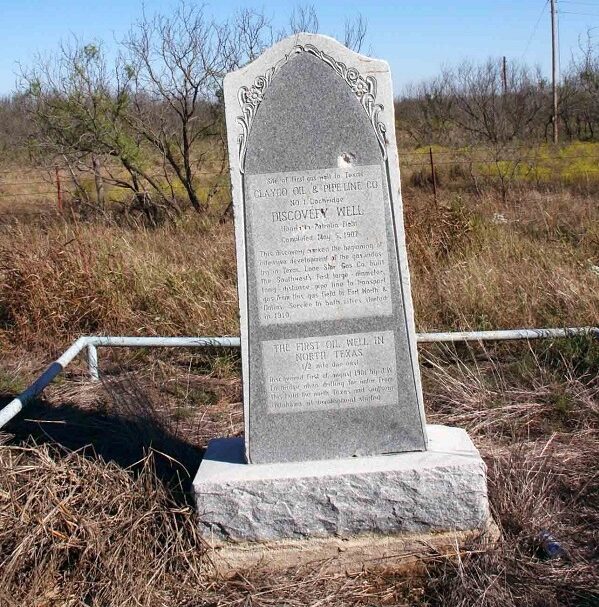

May 5, 1907 – A Marker to North Texas Petroleum History

Outside Oil City (today Petrolia), Texas, the Clayco Oil & Pipe Line Company completed its Lochridge No.1 well, “site of the first gas well in Texas,” according to a granite marker that credits local rancher J.W. Lochridge for the discovery east of Wichita Falls.

“This discovery marked the beginning of intensive development of the gas industry in Texas,” the marker explains. Lochridge had been disappointed with a 1901 well that produced some oil, which he used in his dipping vats to rid his cattle of parasites, according to a 2016 article in North Texas Farm & Ranch.

Clayco Oil & Pipe Line Company commemorated its 1907 discovery in North Texas with a marker that has endured near Highway 148 south of Petrolia.

The Clayco Oil & Pipe Line Company marker in the Henrietta-Petrolia field acknowledges Lone Star Gas Company for constructing the state’s first large-diameter natural gas pipeline in 1920 to Fort Worth and Dallas. Lone Star Gas changed its name to Enserch Corporation in 1975.

May 7, 1920 – Halliburton founds Well Cementing Company

As mid-continent oil and gas discoveries continued, Erle Palmer Halliburton founded the Halliburton Company as an oilfield well service and cementing company. The Wilson, Oklahoma, venture succeeded his New Method Oil Cementing Company, established a year earlier during the Burkburnett oil boom in North Texas.

In 1922, Halliburton patented an innovative “jet-cement” mixer that increased the speed and quality of the mixing process. By the end of the year, 17 Halliburton trucks were cementing wells in Texas, Oklahoma, Louisiana, and Arkansas. Cement injection protects the well casing, seals off water formations from the oil, and minimizes the danger of blowouts.

The company introduced cement pumps powered by truck motors (instead of steam from the rig boiler) and a device that allowed testing of a formation without setting casing. Halliburton was the first to offer self-contained cementing units operating under their own power. More advances in cementing technology followed.

Learn more in Halliburton cements Wells.

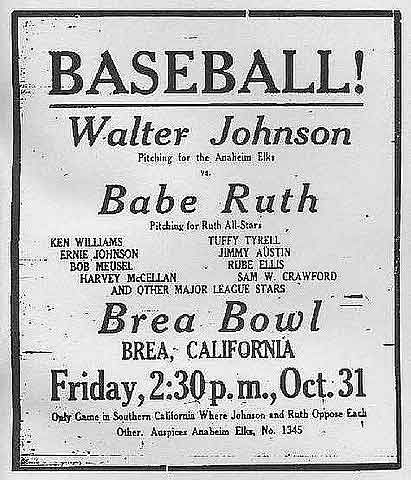

May 8, 1918 – Shreveport Gassers go Extra Innings

As baseball became America’s favorite pastime, the Texas League’s Shreveport Gassers played 20 innings against the Fort Worth Panthers before the game was declared a tie. The Gassers were just one of many oilfield-related teams in the National Association of Professional Baseball Leagues, today known as Minor League Baseball.

Former Olinda Oil Wells pitcher Walter Johnson joined Babe Ruth for a 1924 exhibition game at Brea, California.

At the time, the leagues’ 96 teams included the Okmulgee Drillers, the Tulsa Oilers, the Independence Producers, the Beaumont Exporters, the Corsicana Oil Citys, the Wichita Falls Spudders, and the Iola Gasbags. In Oklahoma oilfields, the Okmulgee Drillers for the first time in baseball history had two players who combined to hit 100 home runs in a single season of 160 games.

Learn more in Oilfields of Dreams.

May 8, 1920 – Burbank field discovered in Oklahoma

Drilling for natural gas 20 miles east of Ponca City, Oklahoma, the Kay County Gas Company’s Bertha Hickman No. 1 well revealed a giant oilfield. Marland Oil & Refining Company assumed control of the discovery well, which produced 150 barrels of oil a day from a depth of about 3,000 feet. The Burbank field would extend over 33 square miles, mostly in Osage County, and produce between 20 million and 31 million barrels of oil annually for the next four years.

E.W. Marland in 1928 built his Ponca City mansion, now a museum. Fellow Oklahoman Will Rogers was a frequent guest.

With Oklahoma petroleum production booming since the Red Fork Gusher of 1901, independent producers agreed to use a 10-acre well spacing for oil conservation. Ernest W. Marland (Oklahoma governor from 1935 to 1939) applied new seismography technologies to discover the Tonkawa oilfield in June 1921. Visit the Marland Estate in Ponca City.

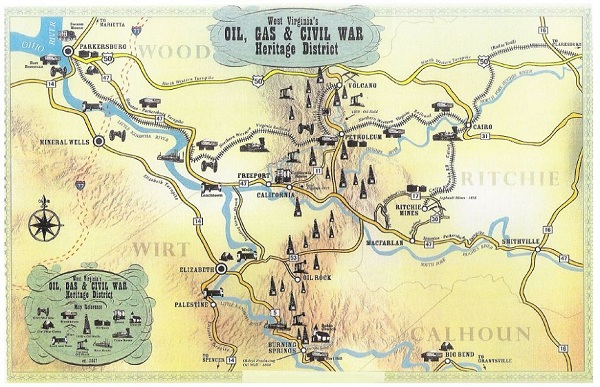

May 9, 1863 – Confederate Cavalry raids Oilfield

Confederate cavalry attacked a thriving oil town near the Ohio River in what would soon become West Virginia. Confederate Gen. William “Grumble” Jones led the rebel cavalry brigade raid on Burning Springs oilfield storage facilities containing thousands of barrels of oil.

Rebels attacked the Burning Springs oilfield on the banks of the Little Kanawha River, just a few miles southeast of Parkersburg and the Ohio River. Heritage district map courtesy Oil & Gas Museum, Parkersburg, West Virginia.

About 1,300 Confederate troopers raided Burning Springs, destroying cable-tools and burning 150,000 barrels of oil. “All the oil, the tanks, barrels, engines for pumping, engine-houses, and wagons — in a word, everything used for raising, holding, or sending it off was burned,” Gen. Jones reported to Gen. Robert E. Lee. The destruction and fires along the Kanawha River marked the first time an oilfield was targeted in warfare, according to West Virginia historian David McKain.

Learn more in Confederates attack Oilfield.

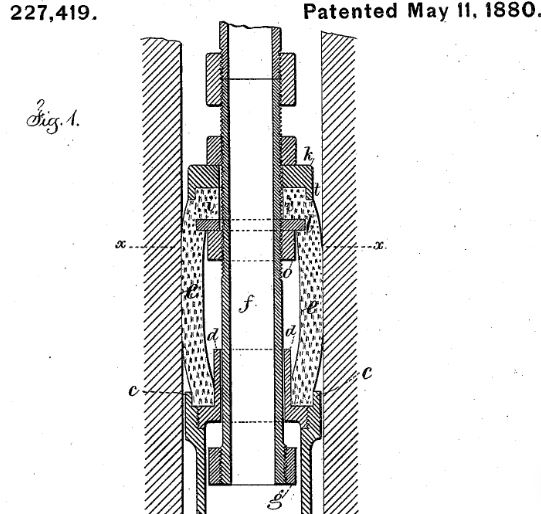

May 11, 1880 – Dresser patents Oil Well Device

Solomon R. Dresser of Bradford, Pennsylvania, patented a rubber “packer” for sealing downhole pressure in wells. The technology behind the patent (no. 227419) helped confine gas, “which enters the well from the lower rocks and utilizes its force or pressure to expel the oil from the well.”

Detail from Solomon R. Dresser 1880 patent for a rubber “packer” to seal downhole pressure in wells.

With the success of his Dresser “Cap Packer” in the giant Bradford oilfield, the inventor founded the S.R. Dresser Manufacturing Company. In 1885, he patented a flexible coupling known as a “Dresser Joint,” a widely adopted pipeline coupling method using rubber for tight seals, which permitted long-range transmission of natural gas.

After expanding into manufacturing oilfield pumps, engines, and compressors, Dresser’s company went public in 1928, moving its headquarters from Bradford to Dallas in 1950. Dresser Industries merged with oilfield supply rival Halliburton for about $7.7 billion in stock in 1998.

Recommended Reading: Erle P. Halliburton, Genius with Cement (1959); Oil in Oklahoma

(1976); Textile League Baseball: South Carolina’s Mill Teams, 1880-1955

(2004); The Civil War and Northwestern Virginia

(2004); Conoco: 125 Years of Energy

(2000); Phillips, The First 66 Years

(1983). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

_______________________

The American Oil & Gas Historical Society preserves U.S. petroleum history. Please become an AOGHS annual supporter and help maintain this energy education website and expand historical research. Contact bawells@aoghs.org. Copyright © 2025 Bruce A. Wells. All rights reserved.