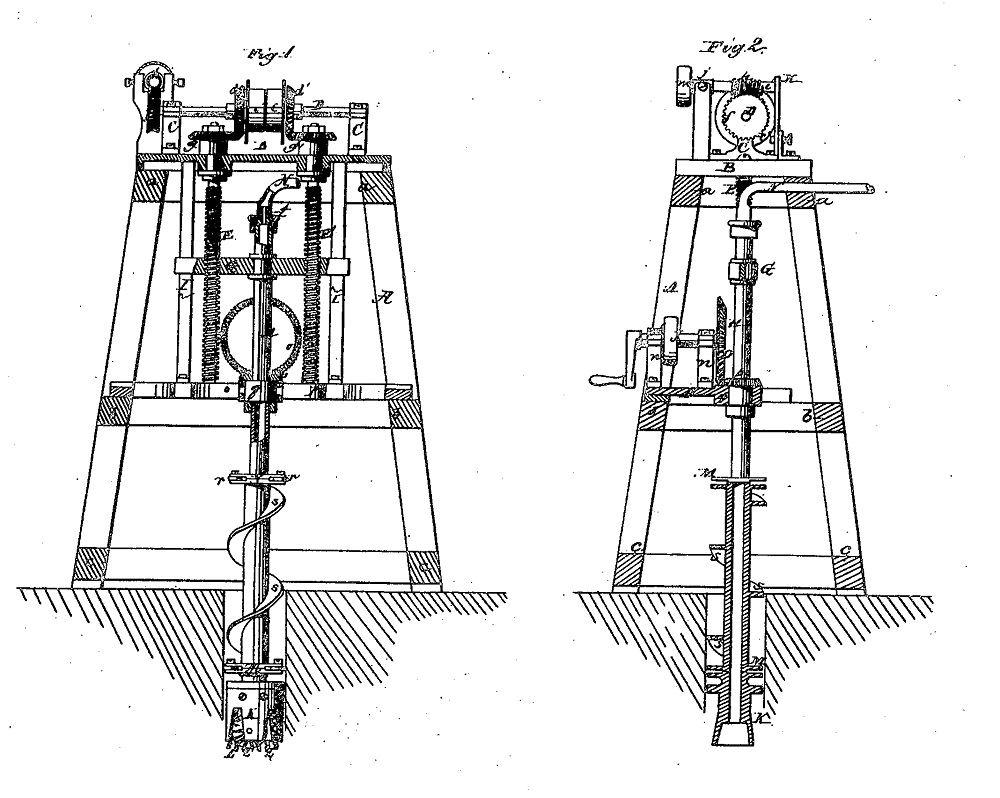

Early patent for a hollow “drill-rod” and roller bit for “making holes in hard rock.”

An “Improvement in Rock Drills” patent issued to a New Yorker after the Civil War included the basic elements of the modern petroleum industry’s rotary rig.

On January 2, 1866, Peter Sweeney of New York City was granted U.S. patent No. 51,902 for a drilling system with many innovative technologies. His rotary rig design, which improved upon an 1844 British patent by Robert Beart, applied the rotary drilling method’s “peculiar construction particularly adapted for boring deep wells.”

Peter Sweeney’s innovative 1866 “Stone Drill” patent included a roller bit using a “rapid rotary motion” that would evolve into modern rotary drilling technologies.

More efficient than traditional cable-tool percussion bits, Sweeney’s patent provided for a roller bit with replaceable cutting wheels such “that by giving the head a rapid rotary motion the wheels cut into the ground or rock and a clean hole is produced.”

Deeper Drilling

The Sweeney design utilized a roller bit with replaceable cutting wheels such “that by giving the head a rapid rotary motion the wheels cut into the ground or rock and a clean hole is produced.

In another innovation, the “drill-rod” was hollow and connected with a hose through which “a current of steam or water can be introduced in such a manner that the discharge of the dirt and dust from the bottom of the hole is facilitated.”

Better than commonly used steam-powered cable-tools, which used heavy rope to lift and drop iron chisel-like bits, Sweeney claimed his drilling apparatus could be used with great advantage for “making holes in hard rock in a horizontal, oblique, or vertical direction.”

Drilling operations could be continued without interruption, Sweeny explained in his patent application, “with the exception of the time required for adding new sections to the drill rod as the depth of the hole increases. The dirt is discharged during the operation of boring and a clean hole is obtained into which the tubing can be introduced without difficulty.”

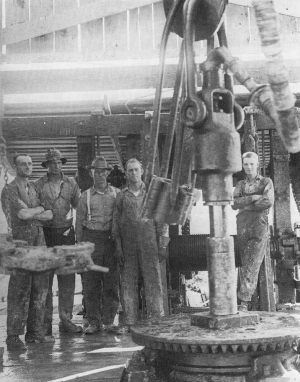

A 1917 rotary rig in the Coalinga, California, oilfield. Courtesy of the Joaquin Valley Geology Organization.

Foreseeing the offshore exploration industry, Sweeney’s patent concluded with a note that “the apparatus can also be used with advantage for submarine operations.”

With the U.S. oil industry’s growth after the first commercial well in 1859, drilling contractors quickly improved upon Sweeney’s idea. A device was fitted to the rotary table that clamped around the drill pipe and turned. As this “kelly bushing” rotated, the pipe rotated and with it the bit downhole. The torque of the rotary table was transmitted to the drill stem.

Thirty-five years after Sweeney’s patent, rotary drilling revolutionized the petroleum industry after a 1901 oil discovery by Capt. Anthony Lucas launched a drilling boom at Spindletop Hill in Texas.

Learn more at Making Hole – Drilling Technology.

_______________________

Recommended Reading: History Of Oil Well Drilling (2007); The Prize: The Epic Quest for Oil, Money & Power (1991); The Extraction State, A History of Natural Gas in America (2021). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

_______________________

The American Oil & Gas Historical Society (AOGHS) preserves U.S. petroleum history. Please become an AOGHS annual supporter and help maintain this energy education website and expand historical research. For more information, contact bawells@aoghs.org. Copyright © 2024 Bruce A. Wells. All rights reserved.

Citation Information – Article Title: “Sweeney’s 1866 Rotary Rig.” Authors: B.A. Wells and K.L. Wells. Website Name: American Oil & Gas Historical Society. URL: https://aoghs.org/technology/1866-patent-rotary-rig. Last Updated: December 27, 2024. Original Published Date: January 2, 2013.