Businesswoman prospered in booming turn-of-century Pennsylvania oilfields.

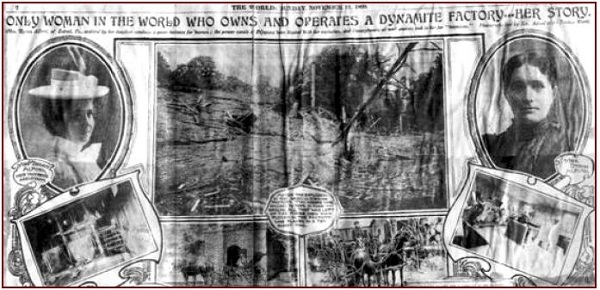

In 1899, Mary Byron Alford, the “Only Woman in the World who Owns and Operates a Dynamite Factory,” prospered in the midst of America’s first billion-dollar oilfield. Mrs. Alford’s oilfield nitro factory cooked 3,000 pounds of nitroglycerin every day.

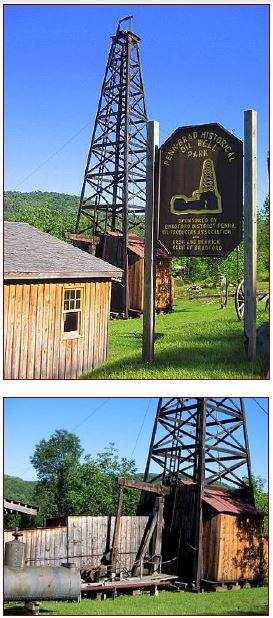

The 85,000-acre Bradford oilfield in north-central McKean County, Pennsylvania, and south-central Cattaraugus County, New York, remains an important part of U.S. petroleum heritage. There are many reasons, including Mary Alford’s pioneering oilfield career at the turn of the century.

Penn-Brad Oil Museum Director Sherri Schulze in 2005 exhibited a laminated (though wrinkled) newspaper article from 1899. “This was done by a student many years ago,” she said. “It was a school project done by one of Mrs. Alford’s descendants.”

“A light golden amber to a deep moss-green in color, the ‘miracle molecule ‘ from the Bradford field is high in paraffin and considered one of the highest grade natural lubricant crude oils in the world,” according to the Penn-Brad Oil Museum and historical oil well park.

In 1881, the Bradford field alone accounted for 83 percent of all the oil produced in the United States.

“It is located about equidistant between the place where oil was first discovered in America and the famous Drake well,” according to a 1929 abstract from the American Association of Petroleum Geologists (AAPG).

Thousands of acres of the oil-rich Bradford sands led to 25,000 producing wells, noted AAPG, adding that the 55 years of productive history, “make it one of the most outstanding oil fields of the world.”

Opened in 1971, the oil museum and park near Bradford, Pennsylvania, continues to preserve a billion-dollar oilfield’s history. Photos by Bruce Wells.

A New York historical marker erected in 1927 in Allegany County Historical Seneca Oil Spring Park commemorated “oil in American continent first recorded” in region 300 years earlier by a Franciscan Friar.

The University of the State of New York and the N.Y. State Oil Producers Association dedicated the tercentenary memorial of Friar Joseph de La Roche D’Allion’s 1627 report.

Oilfield Nitro Factory

In November 1899, the New York World newspaper featured the world-famous Bradford oilfield — and a nitroglycerin company run by a woman more than two decades before women won the right to vote.

“It is an odd business for a woman to be in,” said Mrs. Alford in the World’s article, “but I know no reason why a woman who understands it cannot manage it as well as a man.”

Alford entered the explosive-making business in 1884 with her husband. Ten years later, as Mr. Alford’s health began to fail, she took over company operations. By 1899, she had increased daily production to 3,000 pounds of nitroglycerin and 6,000 pounds of dynamite.

“She did most all of the business duties including; purchasing chemicals, pay roll, sales, billing and shipping, hands on visiting of the factory manufacturing,” notes one historian (writing about the National Powder Company). “She was known to keep late nights working until midnight.

Demand was high since nitroglycerin detonations — “shooting” a well — increased a well’s production from petroleum bearing formations.

Learn more about well fracturing in Shooters – A “Fracking” History.

Mrs. Alford’s manufacturing plant consisted of 12 cheaply built and unpainted wood buildings located outside of Eldred, Pennsylvania. Brick buildings would have been prettier at her nitro factory, Alford told the New York newspaper, but it would cost more to replace them.

“The owner of a nitroglycerin factory never knows beforehand when it is going to blow up or afterward why it did blow up,” the article explained. “There is never anyone to explain how it happened.”

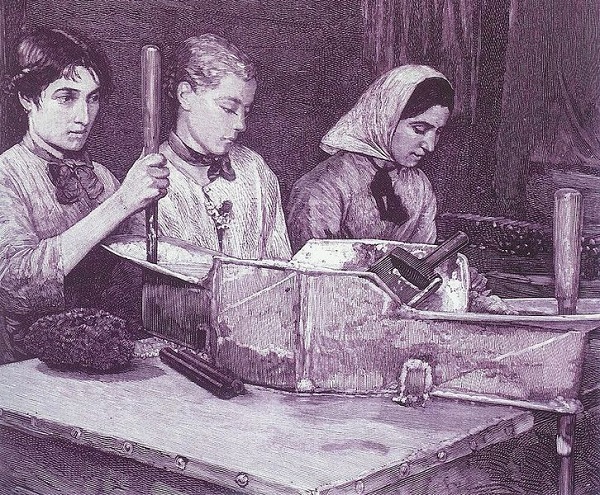

Illustration of women hand mixing nitroglycerin ingredients at a “Dynamitfabrik” in Isleten, Switzerland, circa 1880.

In 1899, the manufacture of nitroglycerin was a primitive, cautious, temperature-sensitive churning of nitric and sulfuric acids with glycerin. Knowing the temperature was vital. “On the accuracy of the thermometer depend the lives of the employees,” Mrs. Alford said.

“When the mixing is done, the liquid is the color of milk,” she added. “It is drawn off into a wooden tank in which there is eighteen inches of cold water. As the milky fluid strikes the water, red fumes light the surface and there is a sound like the hissing of geese.”

If successful, the nitroglycerin settled to the bottom of the wooden tank. Poured and readied for transport, an eight-quart can weighed 26 pounds and sold for $8 dollars. It was delivered by wagon — trains would not transport nitroglycerin for any price.

Mrs. Alford maintained that if people were kind to nitroglycerin, they could live with it for a long time, despite her own close call. She lived with her husband and daughter only about 80-yards from their factory.

One evening, an employee may have absent-mindedly lit a match or otherwise erred. The oilfield nitro factory and the Alford’s home were obliterated and the family buried under the debris. Neighbors dug them out to find they were not seriously injured. They rebuilt and started again.

Meanwhile, Mrs. Alford raised her daughter, Dessie, in the business.

“Dessie is my right bower,” she said. “I believe in bringing up a girl to work, even if it is not necessary from a financial point of view. Riches, if they fly away, do not work so much hardship for a girl who has been taught to work.”

The 19th century oilfield was a dangerous place — made even more so by nitroglycerin. Despite the hazards, Mrs. Alford lived long and prospered. She died of natural causes in 1924 at the age of 77. Daughter Dessie followed in 1947 at 79.

A 2016 fall open house celebration at the Penn-Brad Oil Museum included Director Sherri Schulze explaining oilfield production equipment to the Bradford Neighborhood of Girl Scouts. Photo courtesy Wade Aiken, Bradford Era.

Today, surrounded by the Allegheny National Forest, Bradford is home to Zippo Manufacturing Company and the American Refining Group, the oldest continuously operating refinery in the United States.

Advanced drilling technologies have led to producing natural gas from a 400-million-year-old rock formation, the Marcellus Shale, according to geologists members of AAPG.

The Penn-Brad Oil Museum includes a replica circa 1880s wooden cable-tool derrick 72 feet tall. Local volunteers and supporters of the nonprofit museum maintain it and other Pennsylvania oil history icons.

_______________________

Recommended Reading: Images of America: Around Bradford (1997); Breaking the Gas Ceiling: Women in the Offshore Oil and Gas Industry (2019); Anomalies, Pioneering Women in Petroleum Geology, 1917-2017 (2017). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

_______________________

The American Oil & Gas Historical Society (AOGHS) preserves U.S. petroleum history. Become an AOGHS annual supporting member and help maintain this energy education website and expand historical research. For more information, contact bawells@aoghs.org. Copyright © 2023 Bruce A. Wells. All rights reserved.

Citation Information – Article Title: “Mrs. Alford’s Nitro Factory.” Authors: B.A. Wells and K.L. Wells. Website Name: American Oil & Gas Historical Society. URL: https://aoghs.org/petroleum-pioneers/mrs-alfords-nitro-factory. Last Updated: November 1, 2023. Original Published Date: September 1, 2005.