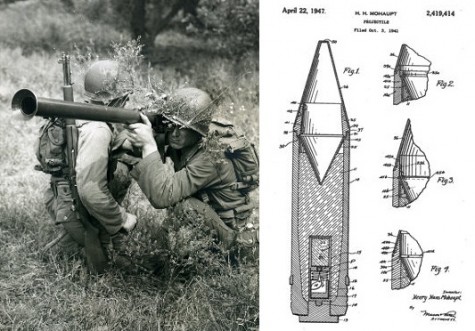

World War II anti-tank weapon improved technologies for perforating well casing.

Swiss inventor Henry Mohaupt used his experience from creating a World War II anti-tank weapon to develop a new technology for improving production of oil and natural gas wells. To improve perforating well casing, he used conically hollowed-out explosive charges to focus each detonation’s energy.

Cement casing, a key oilfield technology developed in 1919 by Erle Halliburton’s New Method Oil Well Cementing Company, Duncan, Oklahoma, isolates wellbore zones and guards against collapse. But far down the borehole, a newly completed well’s cemented casing stands between the petroleum company’s huge investment and the production of oil or natural gas.

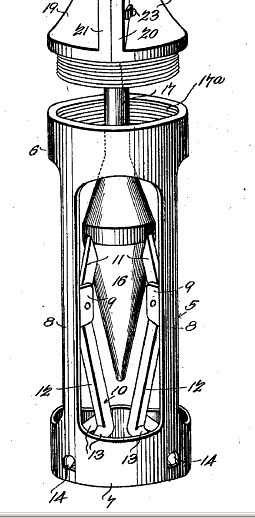

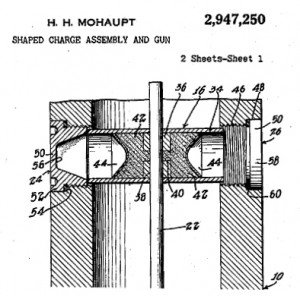

After World War II, Henry H. Mohaupt received several U.S. patents for his “Shaped Charge Assembly and Gun” based on anti-tank technologies he had invented a decade earlier — including a conically hollowed out explosive fired from bazookas.

In the early days of well “perforating” technology, a variety of mechanical means of penetrating casings were used. The U.S. Patent Office records many technologies designed to solve the problem of safely perforating well casing.

Perforating Levers, Scissors and Bullets

In 1902, one invention, Thomas Clark’s “device for perforating well-casings” (patent no. 702,128), relied upon a scissors-like expanding mechanism to drive and then retract “perforating levers” through the casing.

Thomas Clark of Visalia, California, patented his device, “for perforating well tubes or casings; and it has for its object to provide a simple and efficient collar for the upper end of the casing of the perforator which maybe quickly and easily applied and removed and which will remain firmly in place.”

A 1902 patent illustration of scissors-like expanding mechanism to drive and then retract “perforating levers” through casing.

Clark’s scissor-like mechanism included sets of levers where the upper ends would be “forced outwardly as the perforating portions of the levers are drawn inwardly.” More complex than other methods, Clark’s invention did not reach the oilfields.

By the 1930s, “bullet” devices using projectiles – usually steel bullets – would become the most popular in the petroleum industry worldwide.

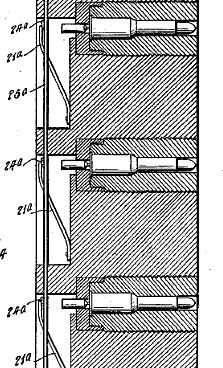

“A device for perforating casing after it has been installed in a well” was designed by Ira J. McCullough of Los Angeles. His April 18, 1939, invention fired down-hole projectiles to increase a well’s production. McCullough received two patents for his multiple bullet-shot casing perforator and mechanical firing system.

The perforating innovation, a technology that simultaneously fired charges at several depths, would improve well production.

The 1930s brought various downhole “guns” that shot steel-jacketed bullets through casing.

“My invention relates to the art of perforating well casing, and relates particularly to a well casing perforating gun for use in perforating, at elevations below the surface, in casing which has already been installed in the well,” McCullough reported in his patent application.

“It is the object of my invention to provide a device for perforating a well after the casing has been installed in the well in which there is plurality of projectiles, each of which is adapted to be propelled by the burning of a separate charge of powder,” McCullough added.

“The charges of powder are simultaneously ignited in order that all of the projectiles will be shot or projected from the apparatus at substantially the same time and with ample force and velocity to penetrate a plurality of casings and intervening walls of cement,” he explained.

McCullough’s device for perforating well casing (patent no. 2155322) also included a “disconnectable means” that – once the charges are lowered into the borehole – can render percussion inoperative as “a safeguard against accidental or inadvertent operation.”

First Perforating Guns

“Across America were numerous cased wells which produced poorly or not at all. Various methods had been tried to get at the oil-bearing formations in these wells – with little success,” explained Noel Atzmiller of Baker Atlas Corporation, Houston. He described the importance of the technology in a 1977 trade magazine article,

“A new and effective method of casing perforation was needed, one that could accurately reach the profitable strata without splitting the casing or breaking the cement-to-casing bonds,” he noted in the article.

The great advancement in well perforating technologies came In 1930, when two enterprising oilfield tool salesmen, Bill Lane and Walt Wells, came up with the idea of using guns to get the oil. The two inventors envisioned a tool which would shoot steel bullets through casing and into the formation.

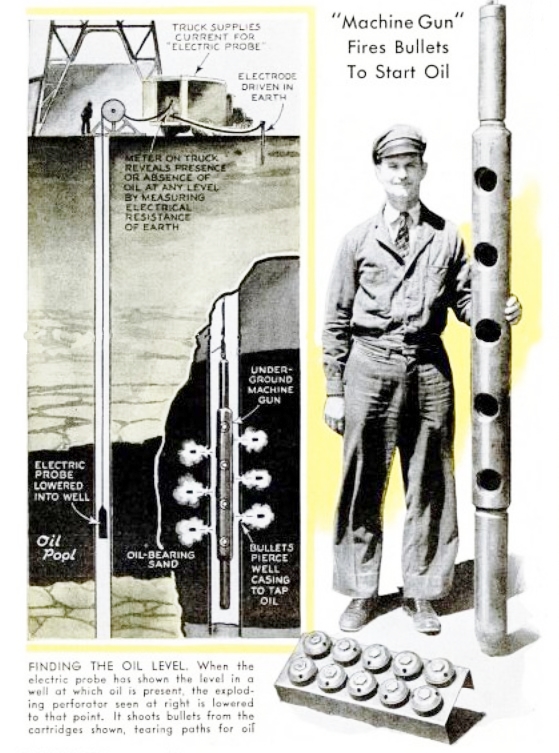

Although not a “machine gun” as noted in this August 1938 Popular Science Monthly article, vital production technologies provide explosive energy to cut through casing and strata – and produce petroleum.

After many tests, the two men created a multiple-shot perforator which fired bullets individually by electrical detonation of the powder charges. “By late 1935 Lane-Wells had a small fleet of trucks, and the company was growing rapidly into being the leading provider of well-perforation technology,” Atzmiller concludes. (Also see Lane-Wells 100,000th Perforation.)

Meanwhile, improved drilling methods made deeper wells possible. An August 1938 Popular Science Monthly article describes exploration and production technologies used for “the deepest hole man has ever made in the crust of the earth” – a 15,000-foot well in Wasco, California.

“Apparently the well had just missed an oil pool, blocked off from it by a formation impervious to oil,” noted the Popular Science article.

At this point, another of the latest scientific aids to oil men, the “underground machine gun,” was called into play. Down the well on the end of a cable went a torpedo-shaped cylinder of steel, studded with recessed knobs along its outer shell. Each knob formed the barrel of a pistol.

As the device reached the 13,100-foot level, a thousand feet below the former world’s deepest “producer,” an operator at the surface closed an electric switch. Slugs of solid steel punctured the well casing and ripped through the surrounding sand. As if released from a bullet riddled tank, oil gushed through the holes and up the pipe…

Inventors continued to scramble and multiple gun barrel type devices assume many forms as the problems of control and “sanding up” of the producing strata are challenged. Solutions will come from battlefields.

Bazooka Technology

The tank was a new and terrible weapon during World War I. Attacks on infantry positions produced chaos. By the 1930s, further advancements in German armor had military planners in England and France scrambling to develop a counter weapon.

Improved perforating technology evolves from the rocket grenade used in the Army’s M1A1 “bazooka.”

Swiss Army veteran and chemical engineer Henry Mohaupt brought his research to America, where the U.S. Army’s Ordnance Department put him in charge of its secret program to develop an anti-tank weapon. Mohaupt’s idea for using a conically hollowed-out explosive charge to direct and focus the detonation’s energy ultimately produced a rocket grenade used in the Army’s 60-millimeter, M1A1 Rocket Launcher – the GI’s bazooka.

After the war, the industrial potential of shaped charges prompted a Fort Worth, Texas, company, Well Explosives Company, to recruit Mohaupt. The inventor’s September 24, 1951, patent submission for a “Shaped Charge Assembly and Gun” brought bazooka technology to the oilfield.

Henry Mohaupt’s leap in oilfield downhole technology used a conically hollowed-out explosive charge to direct and focus the detonation’s energy.

“This invention relates to improvements in means for perforating casing in wells and for perforating and fracturing earth formations around well bores,” Mohaupt explained in his patent application for the new downhole technology.

Focused explosive energy easily cut through casing and strata. In the coming years, Welex Jet Services (Well Explosives Company in 1948 had changed its name to avoid the word “explosives”), continued to explore the opportunities. DuPont, maker of shaped charges, was also interested in oilfield applications.

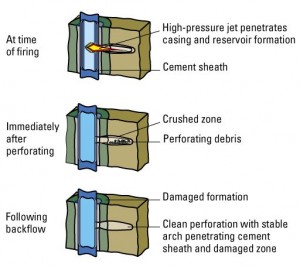

Almost any drilling process will create some damage to the formation adjacent to the wellbore. Bypassing the damage is a key objective when perforating. Image courtesy Schlumberger.

Today, petroleum industry R&D creates technologies to go safer and deeper into tighter zones and more sensitive environments than ever before – and a new generation of patents reflects the demands of higher pressures.

Editor’s Note – Noel Atzmiller’s article about the gun perforator, “Shooting through Steel and Rock,” is in the August 2007 Hart’s E&P magazine. Learn more about the evolution of technologies for increasing oil and natural gas production in Shooters – A “Fracking” History.

_______________________

Recommended Reading: The Bazooka (2012); Wireline: A History of the Well Logging and Perforating Business in the Oil Fields

(1990). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

_______________________

The American Oil & Gas Historical Society (AOGHS) preserves U.S. petroleum history. Please become an AOGHS annual supporter and help maintain this energy education website and expand historical research. For more information, contact bawells@aoghs.org. © 2024 Bruce A. Wells. All rights reserved.

Citation Information: Article Title: “Downhole Bazooka.” Authors: B.A. Wells and K.L. Wells. Website Name: American Oil & Gas Historical Society. URL: aoghs.org/technology/oil-well-perforating-guns. Last Updated: April 10, 2024. Original Published Date: September 21, 2014.